A riveting device for the bottom of the inner container of a galvanized steel refrigerator

A freezer liner and riveting device technology, applied in the field of galvanized sheet freezer liner bottom riveting device, can solve the problems of easy corrosion, high process requirements, affecting product quality, etc., and achieve the effect of ensuring quality and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

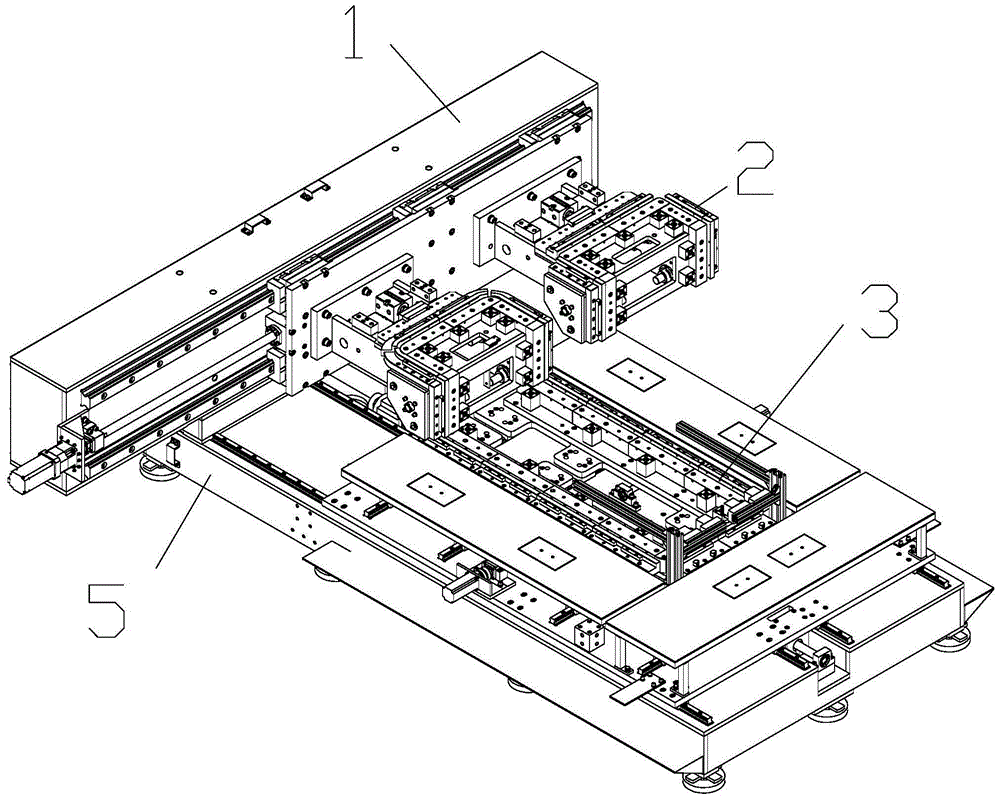

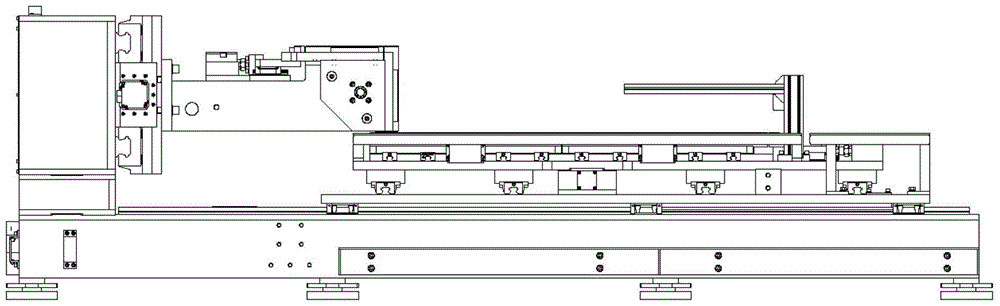

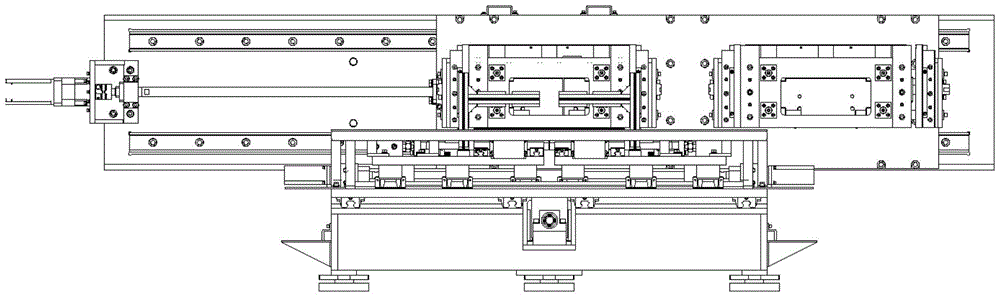

[0043] Embodiment 1: as Figure 1-3 As shown, a riveting device for the bottom of the liner of a galvanized steel freezer includes a base 5, one end of the base 5 is equipped with a sliding beam mechanism 1, and a plurality of small coaming riveting mechanisms 2 are installed on the sliding beam mechanism 1. The front of the seat 5 is equipped with a large coaming riveting mechanism 3;

[0044] The small coaming riveting mechanism 2 can move left and right under the drive of the sliding beam mechanism 1; the large coaming riveting mechanism 3 and the small coaming riveting mechanism 2 cooperate to realize the large coaming 4-1 and the small coaming 4-2 Respectively with the riveting of the bottom plate 4-3.

[0045] refer to Figure 4 As shown, in the above-mentioned device, the sliding beam mechanism 1 includes a beam main body 1-4, and the beam main body 1-4 is installed on the base 5 through a beam base 1-8, and a servo motor 1-4 is installed at one end of the beam main b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com