Furniture based on fishing rope knot and manufacturing process thereof

A production process and furniture technology, applied in the field of fishing rope knots, can solve the problems of troublesome operation, time-consuming, difficult to repair or recycle, etc., and achieve the effects of convenient connection, reduced difficulty, good elasticity and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

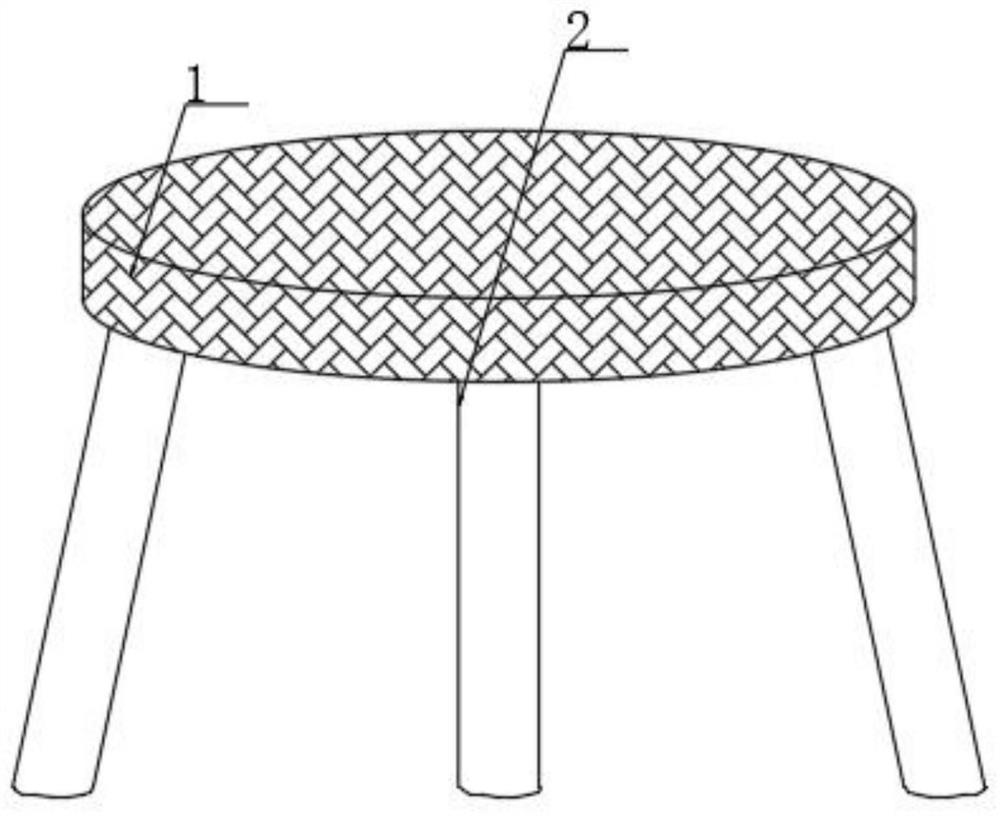

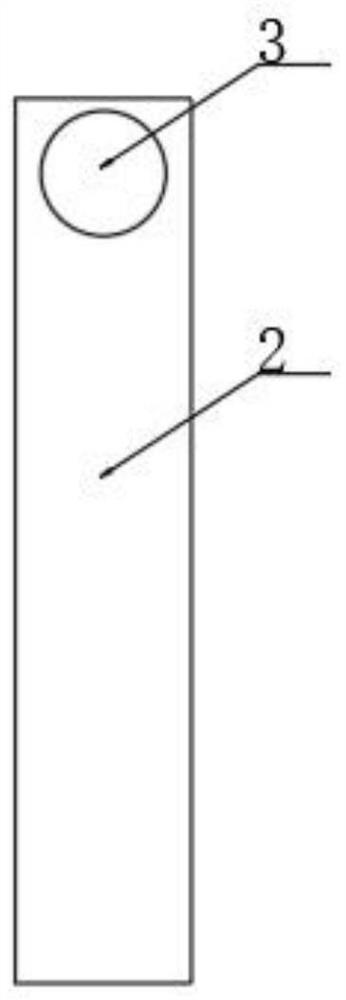

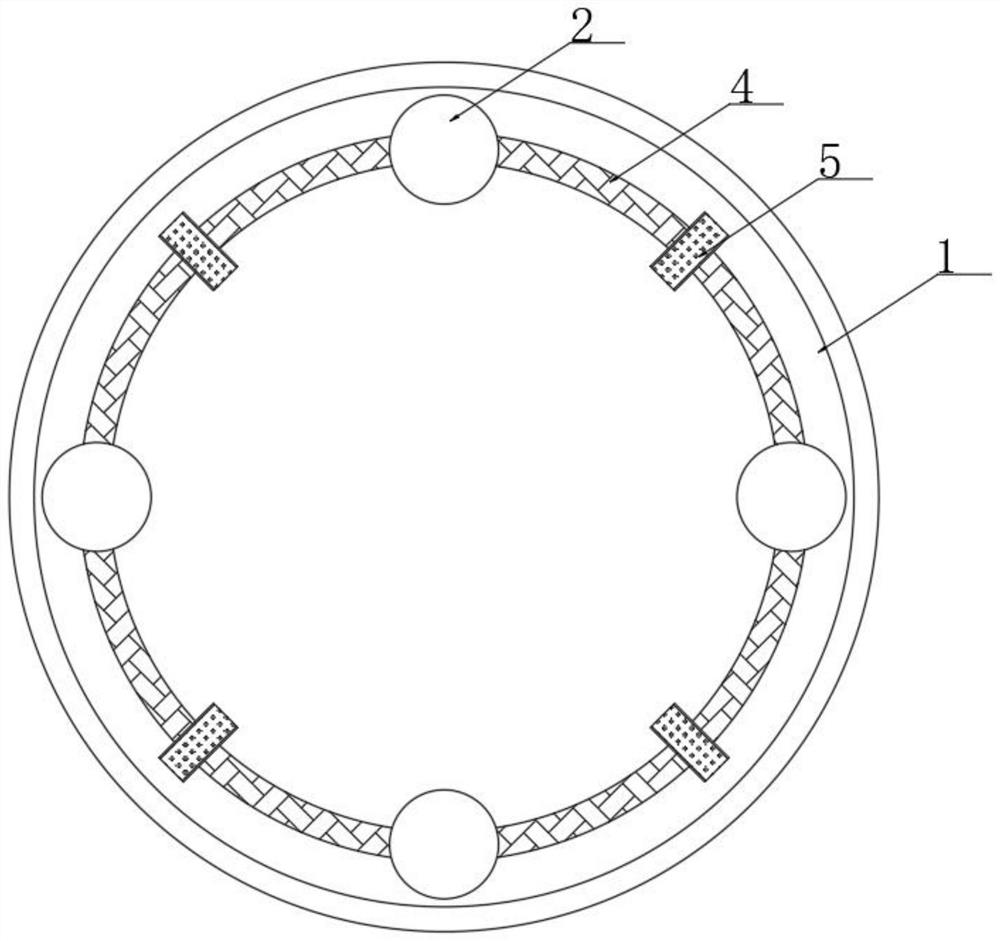

[0030] according to Figure 1-4 The shown furniture based on fishing rope knots includes a seat plate 1, four pillars 2 are arranged at the four corners of the bottom end of the seat plate 1, and a through hole 3 is opened at the inner end of the pillar 2, and the pillars One end of the 2 is provided with a ferrule 4, and the ferrule 4 is connected to the four pillars 2 through the through hole 3, and the outer surface of the ferrule 4 is provided with a rope buckle 5, and one end of the rope buckle 5 is connected to the The seat plate 1 is integrally connected.

[0031] In a preferred embodiment, the material of the seat plate 1 , the ferrule 4 and the cord buckle 5 are all plastic fibers.

[0032] A kind of furniture manufacture technology based on fishing rope knot, described comprises the steps:

[0033] Step 1: Select materials, select a number of plastic fibers and wood, and screen out the unqualified parts;

[0034] Step 2: Preliminary treatment, the selected plastic...

Embodiment 2

[0047] A kind of furniture based on fishing rope knots, comprising a seat plate 1, four pillars 2 are arranged at the four corners of the bottom end of the seat plate 1, a through hole 3 is opened at one end of the pillar 2, and a through hole 3 is opened at one end of the pillar 2 A ferrule 4 is sleeved, and the ferrule 4 is connected to the four pillars 2 through the through hole 3. The outer surface of the ferrule 4 is covered with a rope buckle 5, and one end of the rope buckle 5 is connected to the seat plate 1 All in one connection.

[0048] In a preferred embodiment, the material of the seat plate 1 , the ferrule 4 and the cord buckle 5 are all plastic fibers.

[0049] A kind of furniture manufacture technology based on fishing rope knot, described comprises the steps:

[0050] Step 1: Select materials, select a number of plastic fibers and wood, and screen out the unqualified parts;

[0051]Step 2: Preliminary treatment, the selected plastic fibers are trimmed by a c...

Embodiment 3

[0064] A kind of furniture based on fishing rope knots, comprising a seat plate 1, four pillars 2 are arranged at the four corners of the bottom end of the seat plate 1, a through hole 3 is opened at one end of the pillar 2, and a through hole 3 is opened at one end of the pillar 2 A ferrule 4 is sleeved, and the ferrule 4 is connected to the four pillars 2 through the through hole 3. The outer surface of the ferrule 4 is covered with a rope buckle 5, and one end of the rope buckle 5 is connected to the seat plate 1 All in one connection.

[0065] In a preferred embodiment, the material of the seat plate 1 , the ferrule 4 and the cord buckle 5 are all plastic fibers.

[0066] A kind of furniture manufacture technology based on fishing rope knot, described comprises the steps:

[0067] Step 1: Select materials, select a number of plastic fibers and wood, and screen out the unqualified parts;

[0068] Step 2: Preliminary treatment, the selected plastic fibers are trimmed by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com