Cleaning apparatus

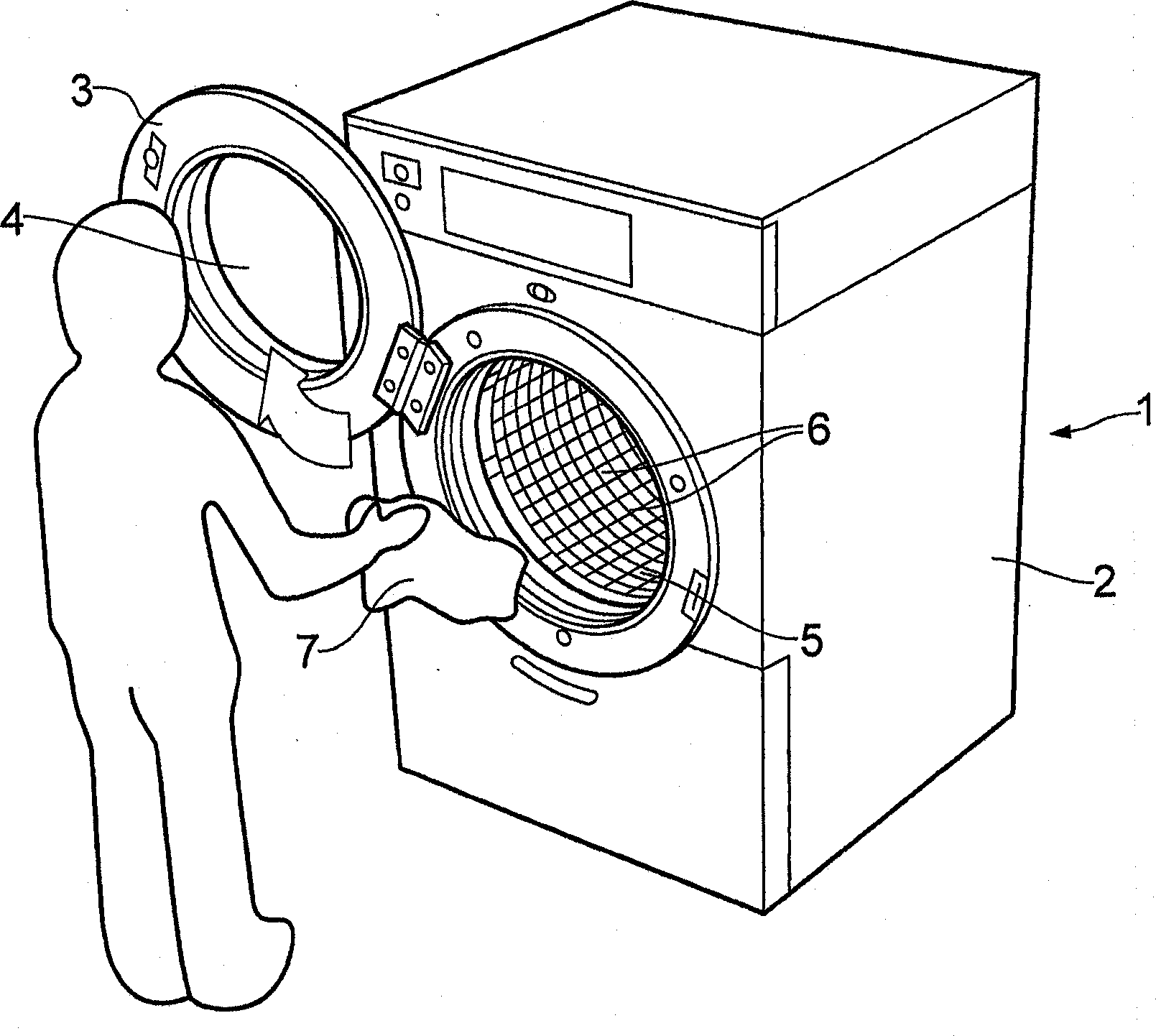

A device, cylindrical technology, used in washing devices, other washing machines, cleaning methods and utensils, etc., which can solve problems such as complexity, low solvency, environmental difficulties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

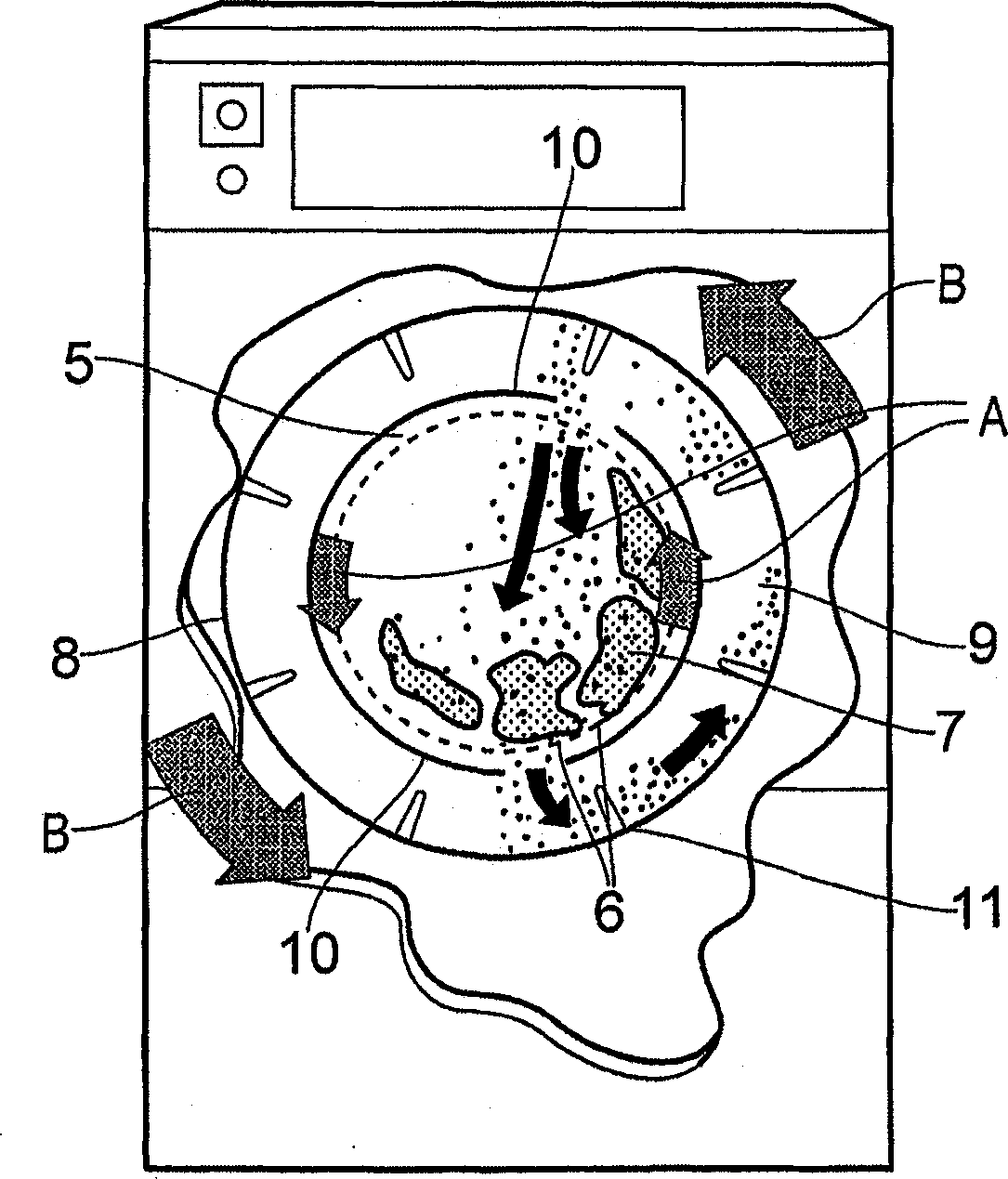

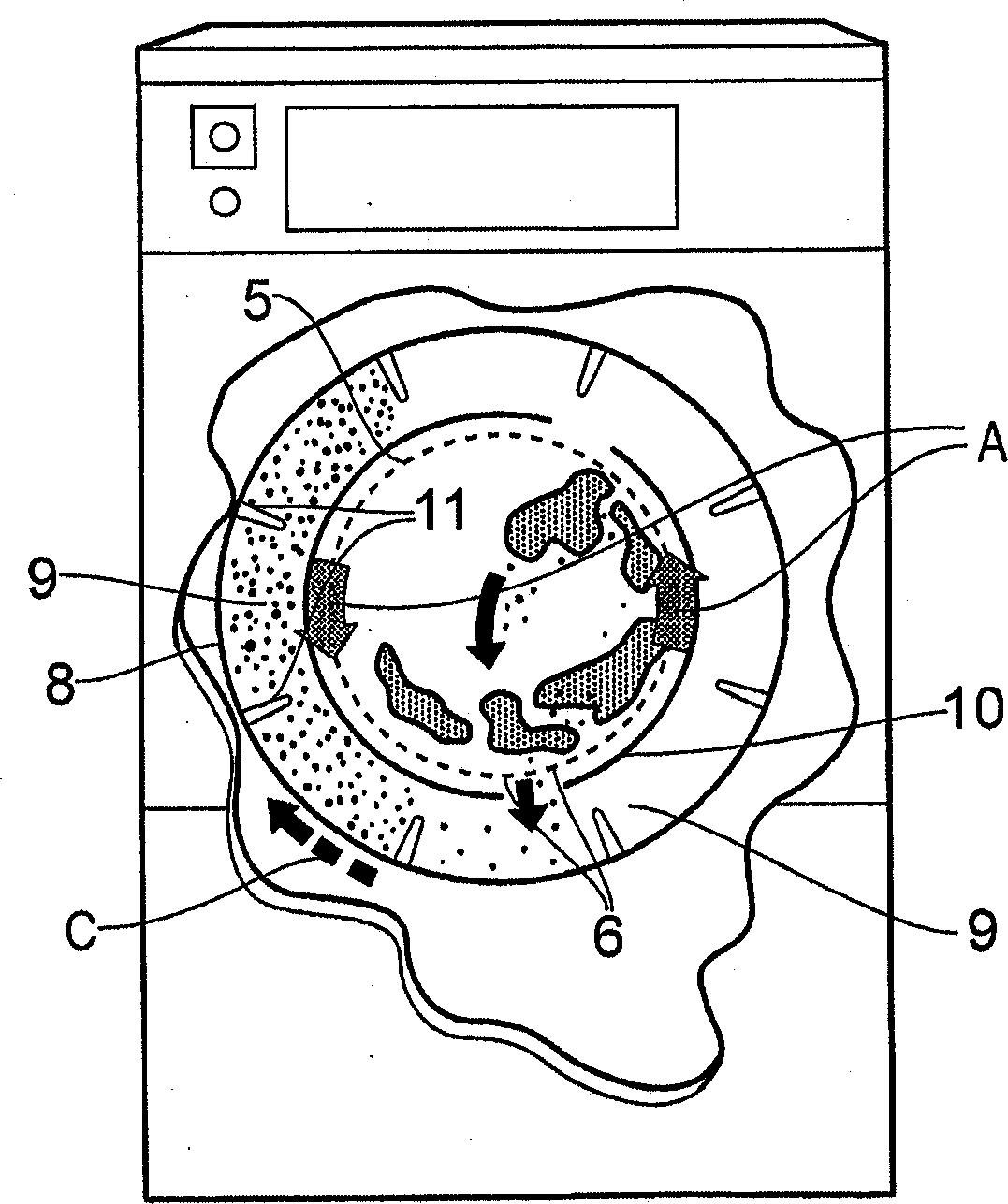

Method used

Image

Examples

example 1

[0075] The polymer particles comprise cylindrical nylon crumbs comprising nylon 6 having a molecular weight in the interval of 15000 Da to 16000 Da, having an average size of 4 mm in length and 2 mm to 3 mm in diameter, and an average particle weight of 30 mg to 40 mg, 6 polymers.

[0076] The fabric to be cleaned comprised soiled and stained nylon 6,6 fibres, and the wetted dyed fibres, were loaded into an apparatus according to the invention containing 75 g (air dry mass) of polymer particles. The temperature was raised to 40°C and held at 40°C for 10 minutes, then increased to 70°C at a rate of 2°C per minute, and then held at 70°C for 20 minutes to complete the wash cycle, after which time removal of nylon debris was performed The crumbs were cycled for 5 minutes, then the fabric was removed from the appliance, rinsed and dried. Complete soil and stain removal was achieved and the fabric was found to be free of residual nylon debris.

example 2

[0078] The fabrics to be cleaned consisted of soiled cloth which was mercerized cotton stained with coffee in a hydrophilic delivery medium. This pre-soiled fabric sample was placed in a device according to the invention containing 75 g (air dry mass) of polymer particles comprising nylon 6 with an average size of 4 mm in length and 4 mm in diameter, 6 Cylindrical crumbs of polymer. Pre-soiled fabric samples were wetted with tap water prior to washing to obtain a 1:1 ratio of substrate to water. The equipment was operated to a maximum temperature of 70°C in a 30 minute wash cycle with a cooling phase at the end of the cycle, followed by a 5 minute cycle to remove nylon debris. Once this time is complete, the washed fabrics are removed from the appliance and dried flat. After the washing process, the degree of soiling of the cloth is very significantly reduced.

example 3

[0080] The fabrics to be cleaned consisted of soiled cloths of mercerized cotton soiled with urban road dust in a hydrophilic transport medium. This pre-soiled fabric sample was placed in a device according to the invention containing 75 g (air dry mass) of polymer particles comprising nylon 6 with an average size of 4 mm in length and 4 mm in diameter, 6 Cylindrical crumbs of polymer. Pre-soiled fabric samples were wetted with tap water prior to washing to obtain a 1:2 ratio of substrate to water. The equipment was operated to a maximum temperature of 70°C in a 30 minute wash cycle with a cooling phase at the end of the cycle, followed by a 5 minute cycle to remove nylon debris. Once this time is complete, the washed fabrics are removed from the appliance and dried flat. After the cleaning process, a significant reduction of dust particles was observed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com