Microorganism-graphene combined treatment method for pig farm breeding wastewater

A technology of joint treatment of aquaculture wastewater, applied in the field of water pollution control, can solve the problems of low removal rate of nitrogen and phosphorus, high energy consumption in operation, poor removal effect, etc., and achieve the effect of strong adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

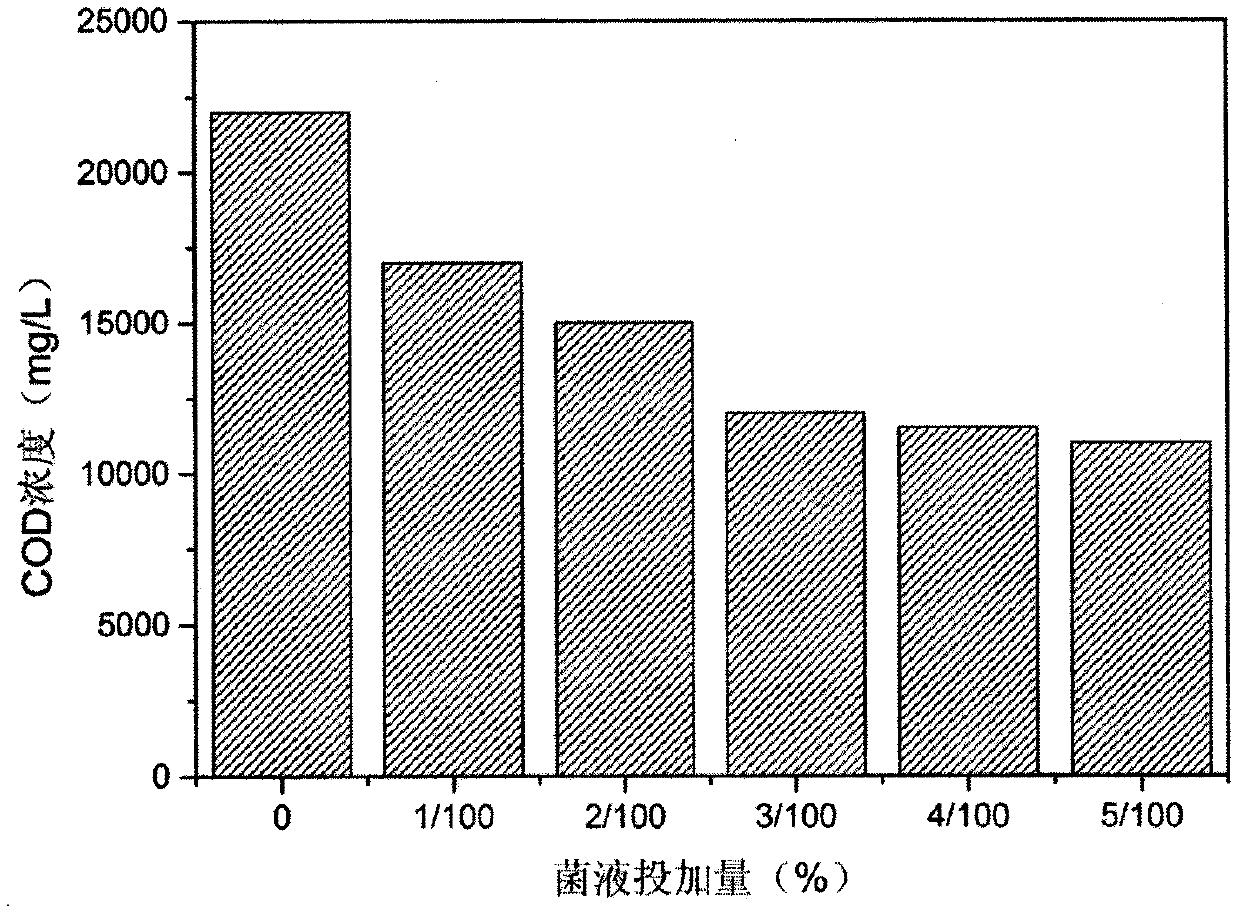

[0030]Shake Pseudomonas flava WD-3 from the LB medium newly inoculated from the solid medium in a constant temperature shaker at 25°C for 12 hours, so that Pseudomonas flava WD-3 is in the logarithmic phase, and then according to the volume ratio of the bacterial solution to the pig farm wastewater 1 %, 2%, 3%, 4%, 5% dosage, taking the COD concentration of pig farm wastewater as a typical evaluation factor, to evaluate the optimal dosage of Pseudomonas flava WD-3. Such as figure 1 As shown, under the conditions of 1%, 2%, 3%, 4%, and 5% of the bacterial solution dosage, the COD removal rates were 22.7%, 31.8%, and 45.5% when the COD concentration was no longer changed. , 47.7% and 50%, according to the change of COD concentration, figure 1 The change trend and the actual dosage of bacteria solution selected 3% as the optimal dosage of Pseudomonas flava WD-3.

Embodiment 2

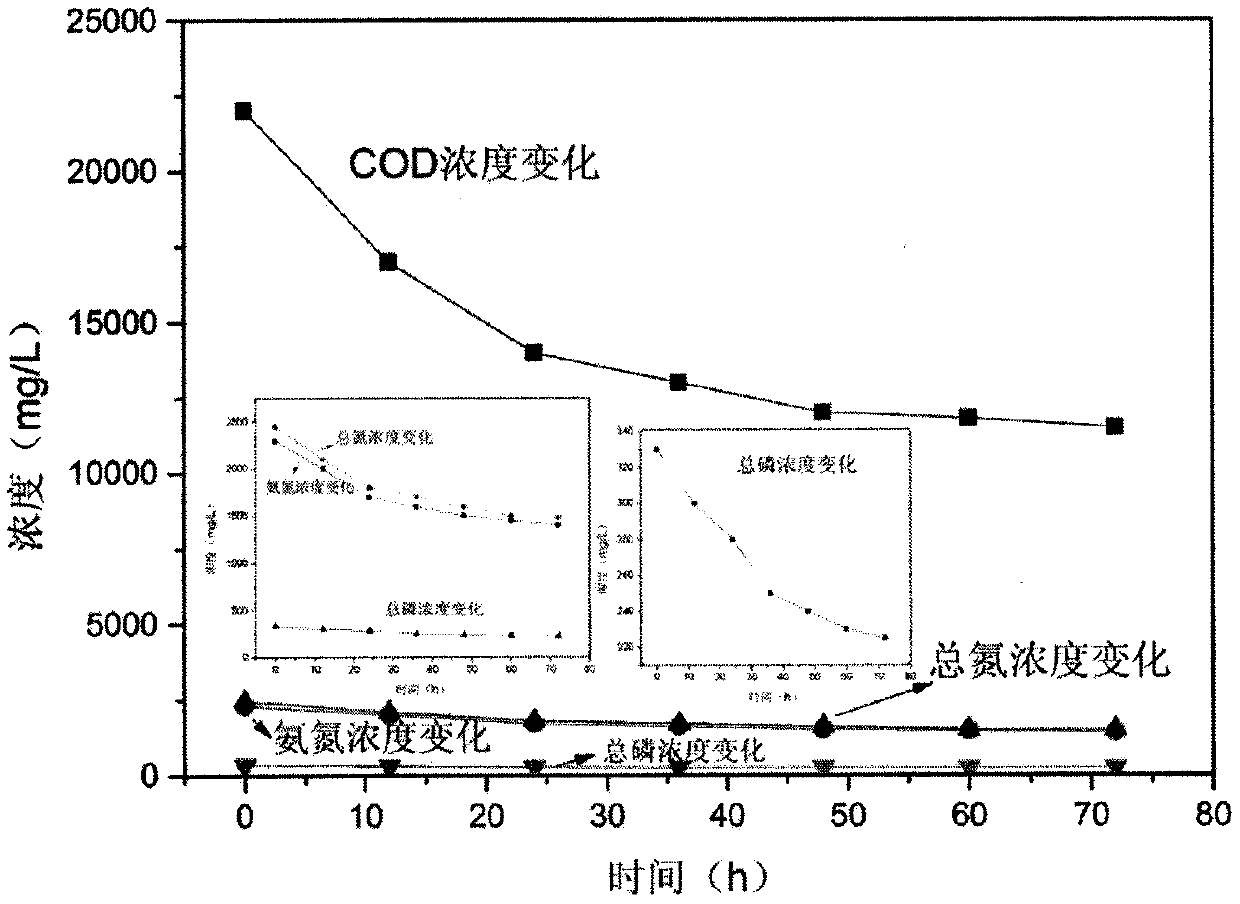

[0032] Add Pseudomonas flava WD-3 with a volume ratio of 3% of the bacterial solution to the pig farm wastewater at different times, and monitor the changes in the concentrations of COD, ammonia nitrogen, total nitrogen, and total phosphorus every 12 hours to determine the concentration of Pseudomonas flava WD. Best reaction time of -3. Such as figure 2 As shown, the concentration of COD, ammonia nitrogen, total nitrogen and total phosphorus showed a gradually decreasing trend with time, and the removal rates of COD at 12h, 24h, 36h, 48h, 60h and 72h were 22.7%, 36.4%, 40.9%, 45.5% %, 46.4% and 47.7%; the removal rates of ammonia nitrogen at 12h, 24h, 36h, 48h, 60h and 72h were 13.0%, 26.1%, 30.4%, 34.8%, 36.9% and 39.1%; total nitrogen at 12h, 24h , 36h, 48h, 60h and 72h removal rates were 14.3%, 26.5%, 30.6%, 35.0%, 38.8% and 39.6%; total phosphorus removal rates at 12h, 24h, 36h, 48h, 60h and 72h were 9.1%, 15.2%, 24.2%, 27.3%, 30.3%, and 31.8%. According to the changes...

Embodiment 3

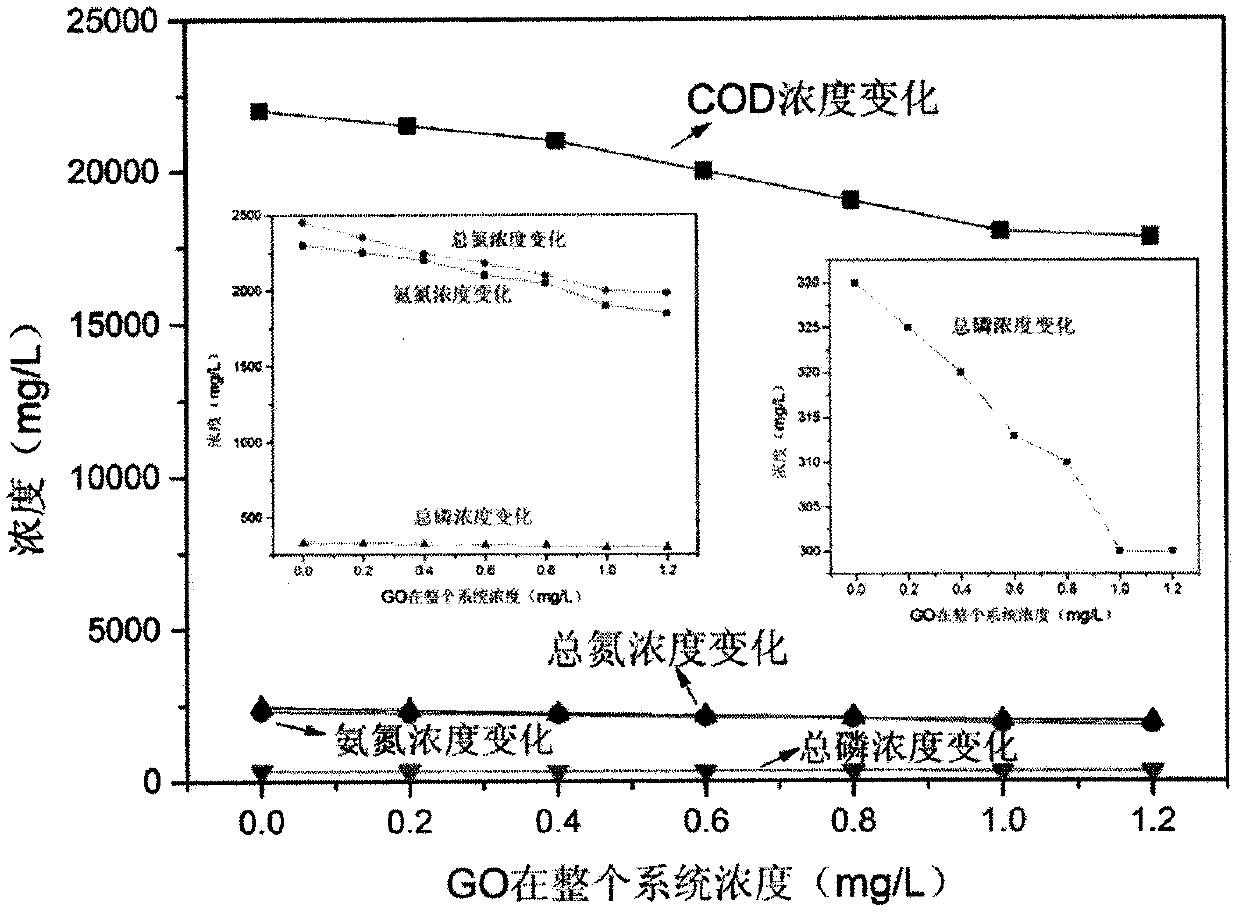

[0034] The concentrated GO solution was added to the pig farm wastewater, so that the concentration of GO in the whole system was 0.2, 0.4, 0.6, 0.8, 1.0, 1.2mg / L, and the optimal reaction concentration of the GO solution was determined. Such as image 3 As shown, the concentrations of COD, ammonia nitrogen, total nitrogen and total phosphorus showed a trend of decreasing gradually with the increase of GO concentration, and the removal rates of COD were 2.3 %, 4.5%, 9.1%, 13.6%, 18.2%, 19.0%; the removal rates of ammonia nitrogen at GO concentrations of 0.2, 0.4, 0.6, 0.8, 1.0, 1.2m8 / L were 2.2%, 4.3%, 8.7% respectively , 10.9%, 17.4%, 19.6%; the removal rates of total nitrogen at GO concentrations of 0.2, 0.4, 0.6, 0.8, 1.0, and 1.2 mg / L were 4.1%, 8.6%, 11.0%, 14.3%, and 18.4%, respectively , 19.2%; the removal rates of total phosphorus at GO concentrations of 0.2, 0.4, 0.6, 0.8, 1.0, and 1.2 mg / L were 1.5%, 3.0%, 5.2%, 6.1%, 9.1%, and 9.1%, respectively. According to the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com