Rotary cutting tool

A technology of cutting tools and knives, which is applied in the direction of rotary cutting tools, manufacturing tools, wood processing appliances, etc., can solve problems such as burrs on one side edge, cutting damage, and hindering the stability of being cut, so as to reduce prices, suppress burrs and Defect effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

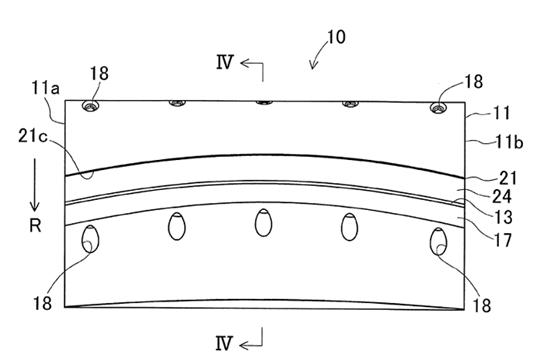

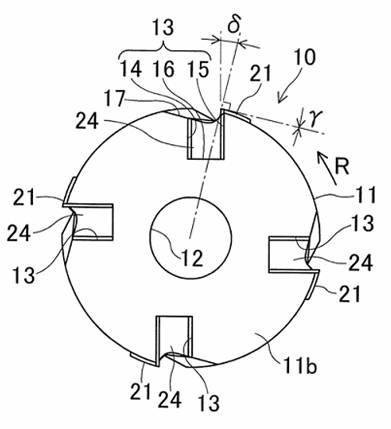

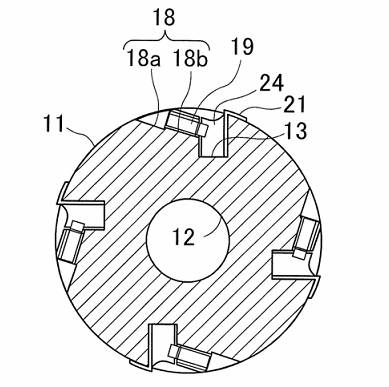

[0027] Such as Figure 1-6 As shown, the body 11 of the rotary cutting tool provided by the present invention is a metal cylinder, and is provided with a hole shaft 12 in the center, and four equidistant points on the outer edge of the cylindrical body 11 are provided with four holes of the same shape. The installation slot 13 is curved in an arc shape opposite to the rotation direction R of the main body 11 , and is symmetrical in the axial direction of the main body 11 . The front wall surface 14 and the rear wall surface 15 of the installation groove 13 are equal in length across, and the bottom wall surface 16 of the installation groove 13 is at right angles to the front wall surface 14 and the rear wall surface 15, and forms a parallel extending plane in the axial direction. After the cutter 21 described later, the inclination angle δ of the rear wall surface 15 relative to the radial direction is 15°, and increases with the bending of the mounting groove 13, and reaches ...

no. 2 example

[0035] Such as Figure 8-9 As shown, the installation groove 33 protrudes toward the direction of the rotation direction R on the outer circumference of the cylindrical body 31, and the bending direction of the metal pressing tool 37 is the same as Figure 5 The direction of bending is shown in the opposite direction.

[0036] In this embodiment, the tool 35 protrudes toward the direction of the rotation direction R of the body 31. The two ends of the blade of the tool 35 have a certain inclination angle relative to the axis of the body 31, and there is a positive angle with respect to the two ends of the body 31. , Negative torsion angle, same as above-mentioned embodiment 1. Therefore, the bending rigidity of the cutter 35 is even higher. Therefore, in Example 2, since the use of relatively expensive materials can be reduced, the price cost is greatly reduced compared to the previous blade with a thickness of 3 mm. Also, in this embodiment 2, the blade 35c has positive an...

no. 3 example

[0038] Such as Figure 10-13As shown, the cylindrical body 41 and the handle 42 are connected on the same axis. There are two symmetrical mounting grooves 43 and two mounting holes 47 on the outer periphery of the body 41 . The front wall surface 44 of the mounting groove 43 is curved in the front direction of the rotation direction R of the main body 41 , the rear wall surface 45 is curved in an arc shape in the opposite direction, and the bottom wall surface 46 forms a plane parallel to the axial direction. In the mounting groove 43, the metal pressing tool 55 on the side of the front wall 44 and the tool pressing tool 61 next to the rear wall surface 45 are installed in the mounting groove 43, and the cutting tool 51 is sandwiched between the metal pressing tool 55 and the tool pressing tool 61.

[0039] The front side 55a of the metal presser 55 is flat with the front wall 44 , the back side 55b is curved outwards in a circular arc when it fits with the rear wall 45 , and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap