Box body welding tracer

A profiling device and box technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effect of simple and compact structure, low manufacturing cost and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

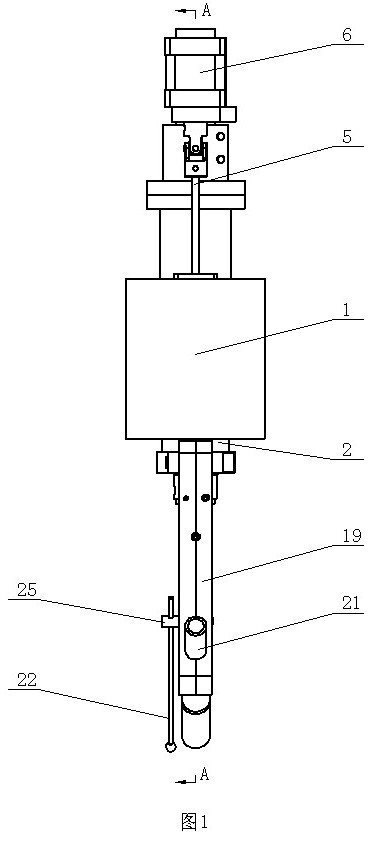

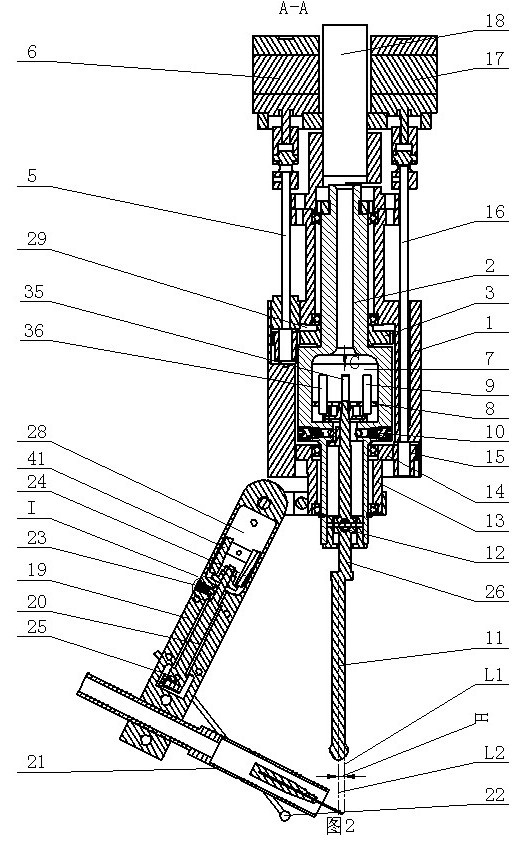

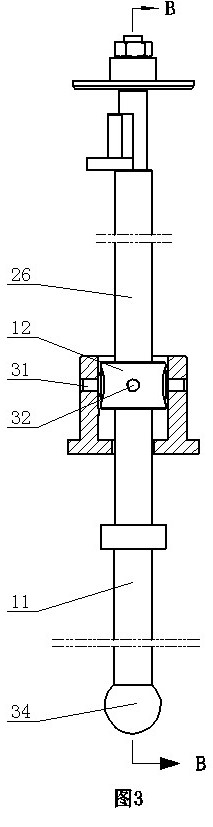

[0009] The box welding profiler of the present invention comprises an outer shell 1, a cavity 29 is provided in the outer shell 1, and an inner shell 2 is installed in the cavity 29, and the inner shell 2 can rotate relative to the outer shell 1. In order to reduce the rotational friction between the inner shell 2 and the outer shell 1, such as figure 2 As shown, a bearing is installed between the outer shell 1 and the inner shell 2. The inner shell rotating device is installed on the outer shell 1, and the execution part of the inner shell rotating device is connected with the inner shell 2 to provide power for the inner shell 2 to rotate relative to the outer shell 1. An inner cavity 7 is provided in the inner shell 2, and the first probe 9, the second probe 35 and the third probe 36 are fixedly installed in the inner cavity 7, and the first probe 9, the second probe 35 and the third probe 36 are not collinear. Such as figure 2 As shown, a universal joint is installed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com