Safety elevator

A technology for safe elevators and elevators, applied to elevators, vertical pipes, building components, etc. in buildings, can solve the problems of prolonging the delivery time of elevators, affecting the normal life of residents, and long construction period, so as to shorten the construction period The effect of shortening the construction period, shortening the construction period, and improving the installation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment one: if Figure 7 Shown, a kind of safety elevator comprises hoistway wall 8, car 2, counterweight 5, and car 2 runs in hoistway wall 8, and hoistway wall 8 of the present embodiment is wall body or civil engineering structure, and car 2 adopts In the traction and drag mode of the existing elevator, the car 2 is connected with the counterweight 5 by the traction sheave 112 and the guide wheel 121 with a wire rope 254 .

[0041] Such as Figure 13 As shown, the elevator described in this embodiment includes a hoistway wall 8, a car frame 21 and a car guide rail located on the hoistway wall 8. The described guide rail is not a common T-shaped guide rail, but a rack guide rail 110. The rack guide rail 110 is symmetrically arranged on the left and right and is fixed on the inner side of the hoistway wall 8 through the guide rail bracket 111. The front side or the rear side of the rack guide rail 110 is provided with a rack, and the bottom of the car frame 21 is ...

Embodiment 2

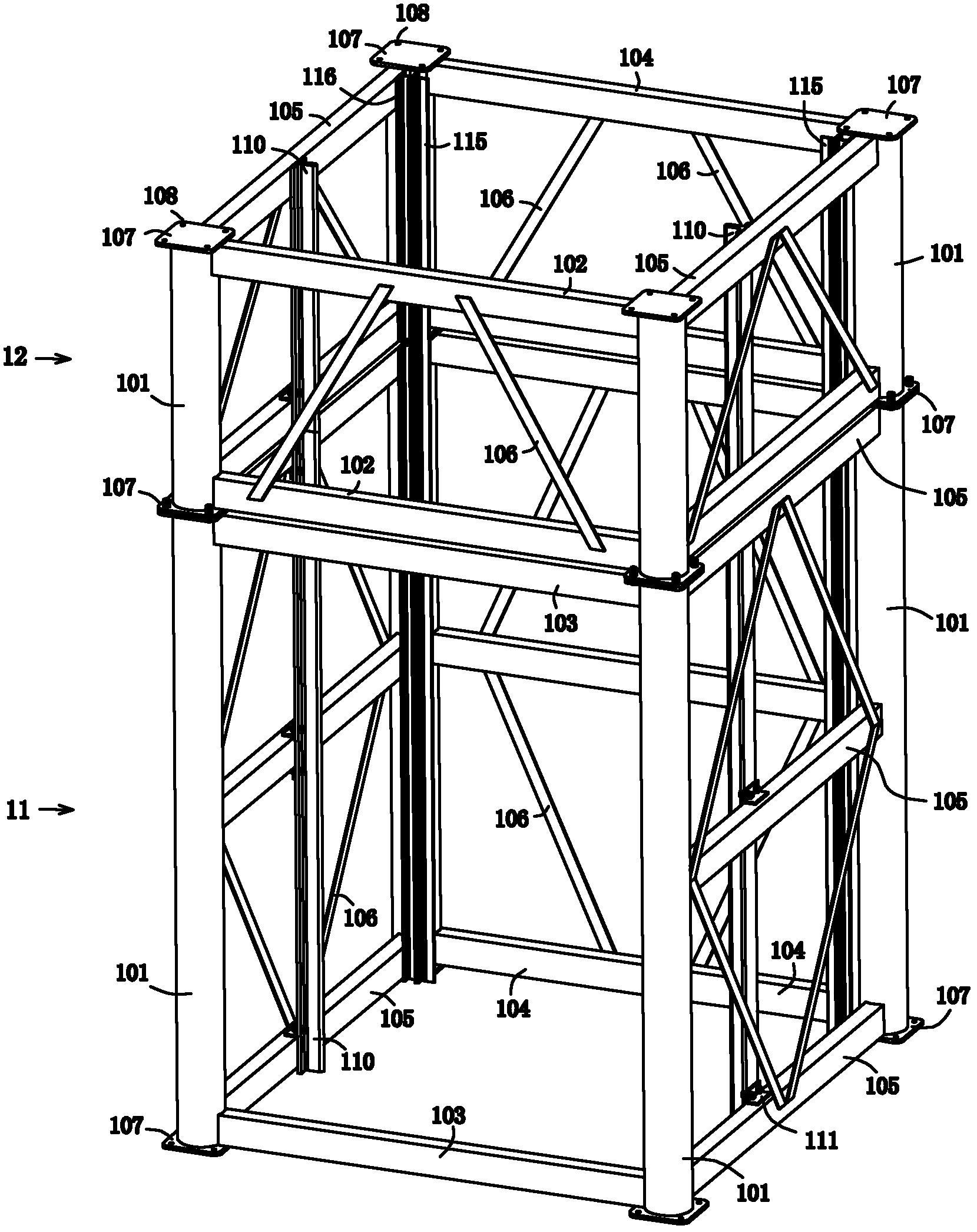

[0046] Embodiment two: if Figure 12 As shown, this embodiment is basically the same as Embodiment 1, the difference is that the hoistway wall 8 is improved. The hoistway wall 8 of this embodiment adopts a metal frame hybrid structure, and the hoistway wall 8 includes a well tower and a bottom pit body 13. The well tower is composed of more than two derricks according to the number of floors where the elevator is installed. 1. It is assembled by lamination of high-strength bolts. The derrick at the bottom of the well tower is called the bottom derrick, and the bottom derrick is horizontally fixed on the pit body 13 by high-strength bolts.

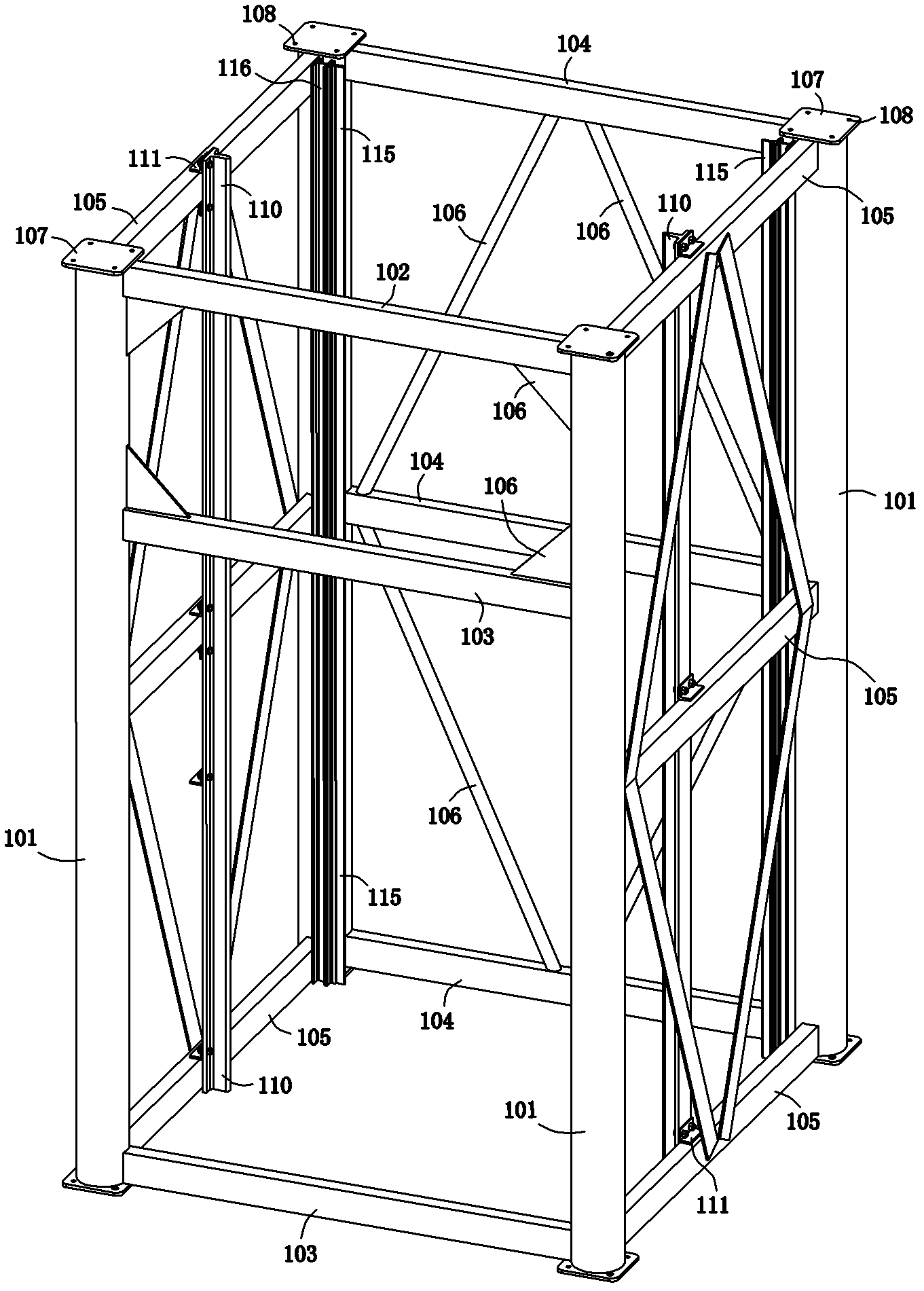

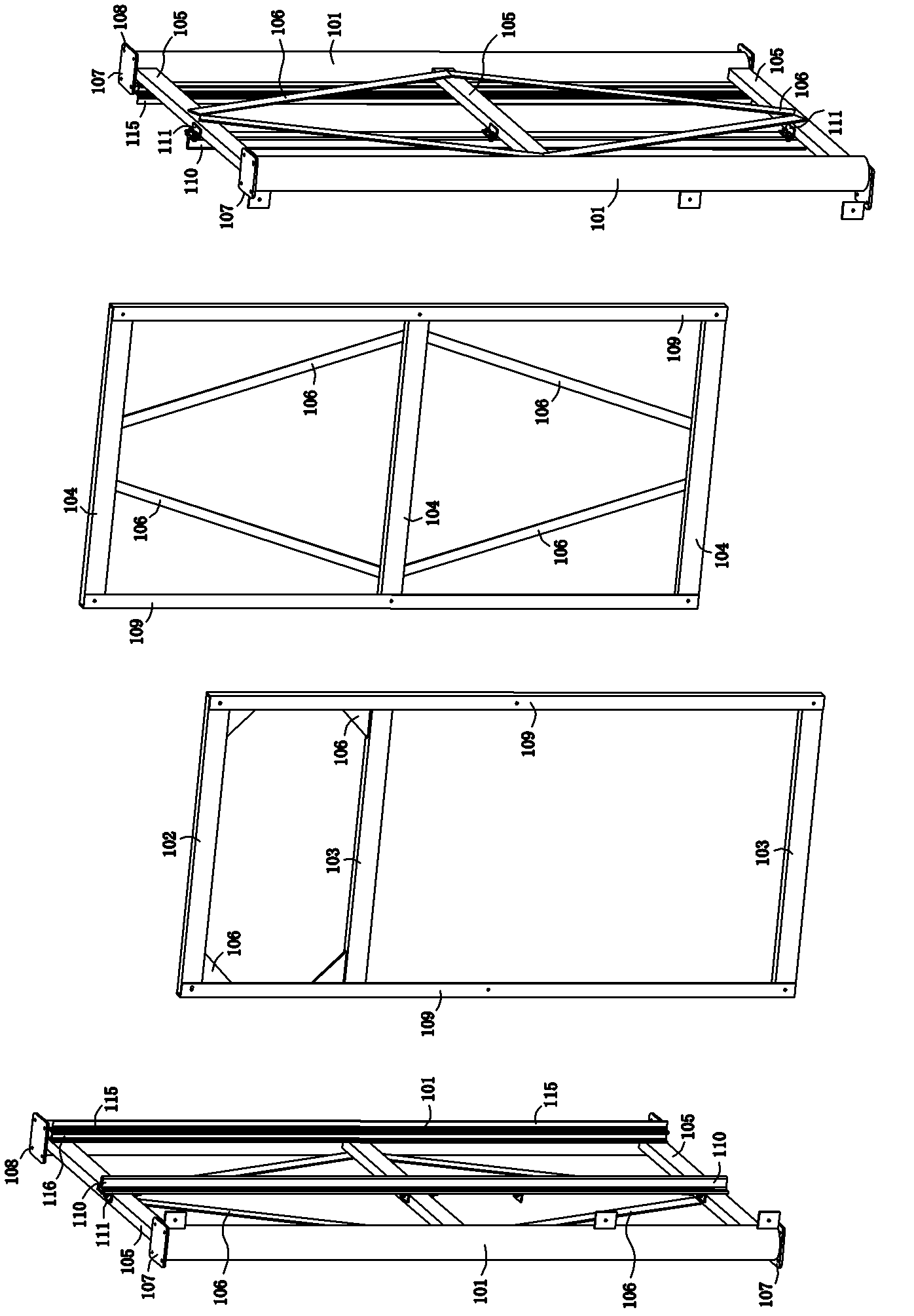

[0047] Such as figure 1 As shown, the derrick 1 includes 4 columns 101, 3 rear beams 104 and 3 left and right side beams 105 respectively. A connecting seat 107 is provided, and the connecting seat 107 is provided with 4 connecting holes 108 (in other embodiments, the connecting holes 108 may also be 3 or more); Then, a brace 106 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com