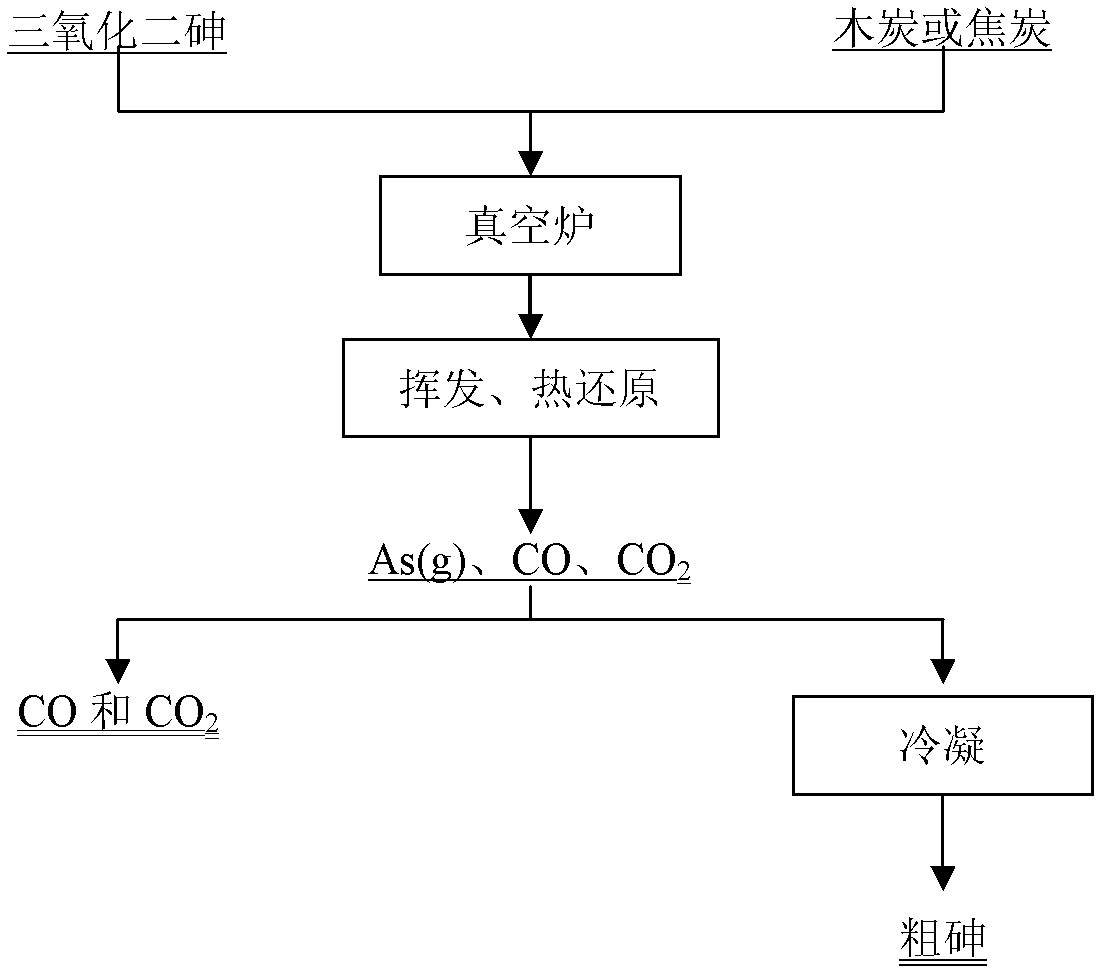

Method for preparing raw arsenic by vacuum carbon thermal reduction of arsenic trioxide

A technology of arsenic trioxide and carbon heat, applied in the field of thermal reduction pyrometallurgy, can solve the problems of difficult control of arsenic reduction atmosphere, corrosion of arsenic to shaft furnace, high production cost, etc., and achieve the effects of no pollution to the environment, high reduction rate and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0012] Embodiment 1 puts 200g charcoal into the reducing agent layer of the vacuum furnace, arsenic ash (As 2 o 3 >90%) 500g into the volatilization crucible of the vacuum furnace, turn on the vacuum system, start to heat up when the pressure is stable (10-12Pa), and raise the temperature of the charcoal layer to 600°C at a speed of 20°C / min. At this time, the pressure in the furnace reaches 31Pa ; Then heat the arsenic trioxide to 400°C. At this time, the pressure in the furnace is 97Pa, and the volatilization temperature is maintained for 4 hours. During the process, the pressure in the furnace fluctuates in the range of 14-186Pa. When the pressure in the furnace is stabilized to about 14Pa, turn off the heating system and wait for natural cooling Finally, the vacuum furnace was opened, and the solid crude arsenic was taken out from the condenser with a purity of 95.3%.

Embodiment 2

[0013] Embodiment 2 1000g coke is put into the reducing agent layer of vacuum furnace, arsenic ash (As 2 o 3 >90%) 2000g into the volatilization crucible of the vacuum furnace, turn on the vacuum system, start to heat up when the pressure is stable (15-18Pa), and raise the temperature of the charcoal layer to 700°C at a speed of 15°C / min, at this time the pressure in the furnace reaches 35Pa ; Then heat the arsenic trioxide to 350°C. At this time, the pressure in the furnace is 104Pa, and the volatilization temperature is maintained for 8 hours. During the process, the pressure in the furnace fluctuates in the range of 21-162Pa. When the pressure in the furnace is stabilized to about 21Pa, turn off the heating system and wait for natural cooling Finally, the vacuum furnace was opened, and the solid crude arsenic was taken out from the condenser with a purity of 96.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com