Backlight module and liquid crystal display device

A technology of backlight module and light guide plate, which is applied to lighting devices, fixed lighting devices, and damage prevention measures of lighting devices, etc. The effect of avoiding shaking, low cost, and avoiding breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

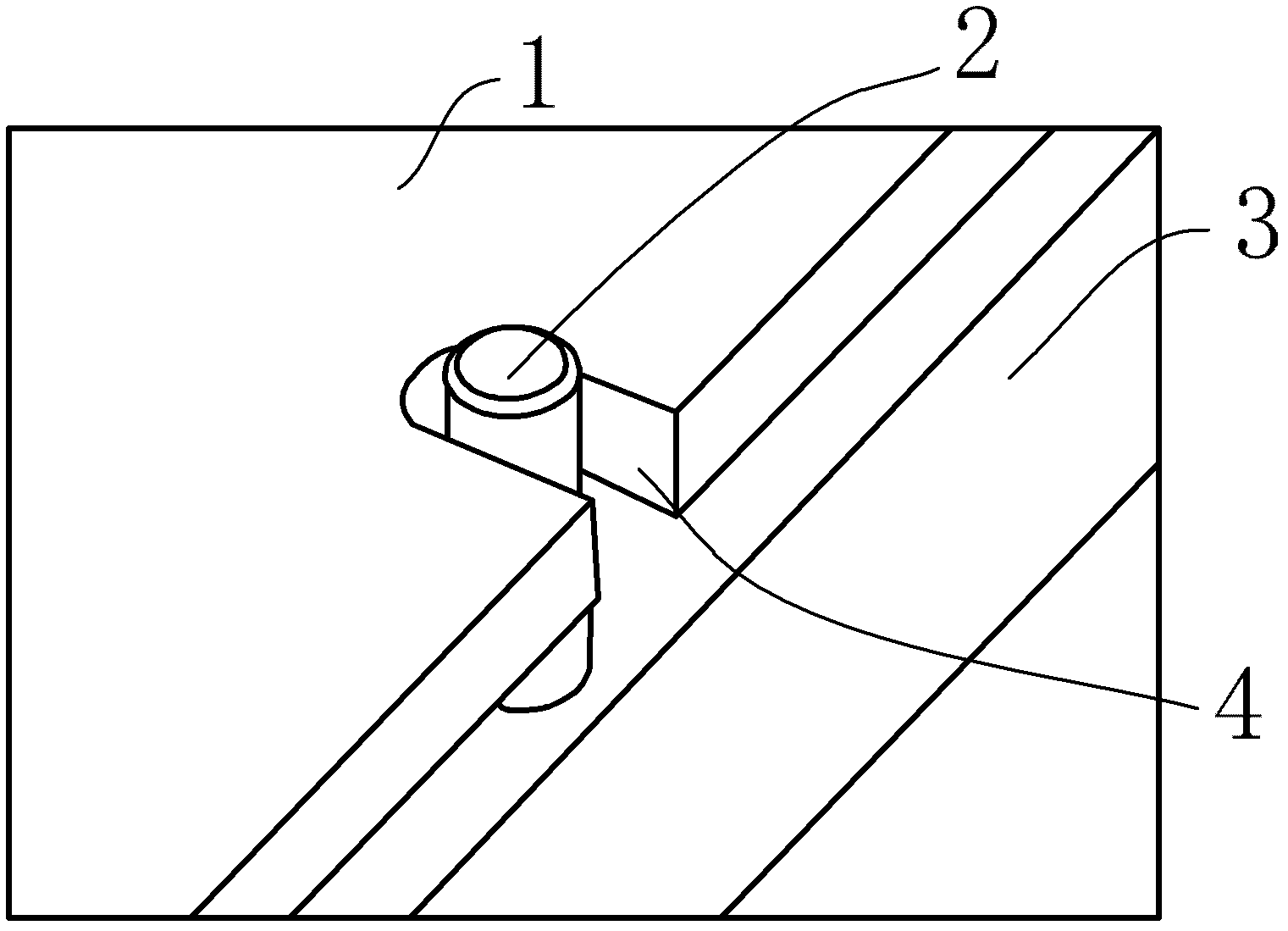

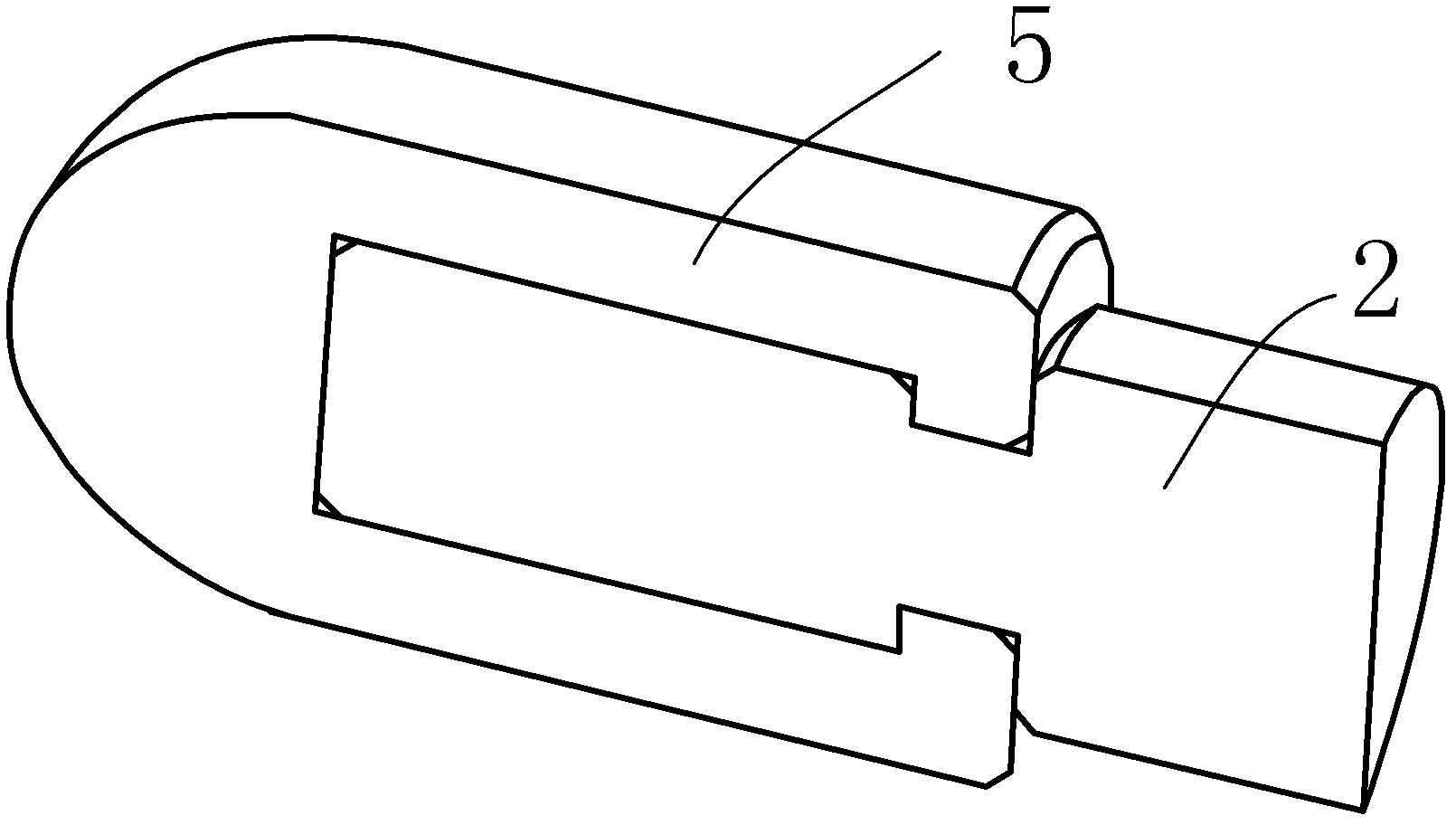

[0025] Such as figure 2 As shown, the rivet column 2 is covered with a buffer sleeve, which is made of silica gel, rubber or other foaming materials, so the buffer sleeve can be a rubber sleeve, and the rubber sleeve is provided with an inwardly extending flange at the opening Correspondingly, grooves are provided on the cylinder of the rivet column 2, and when the rubber sleeve is inserted into the cylinder, the flange can be embedded in the groove to realize the fastening of the rubber sleeve. In order to ensure the cushioning effect of the rubber sleeve, the thickness of the rubber sleeve should not be less than 1.2mm.

[0026] The method of adopting the rubber sleeve is simple in process, as long as it is installed on the existing rivet column 2, it is convenient for production and use.

[0027] The groove also surrounds the entire cylindrical surface of the rivet post, and correspondingly, the flange is also an annular flange. The ring-shaped flange and the groove coop...

Embodiment 2

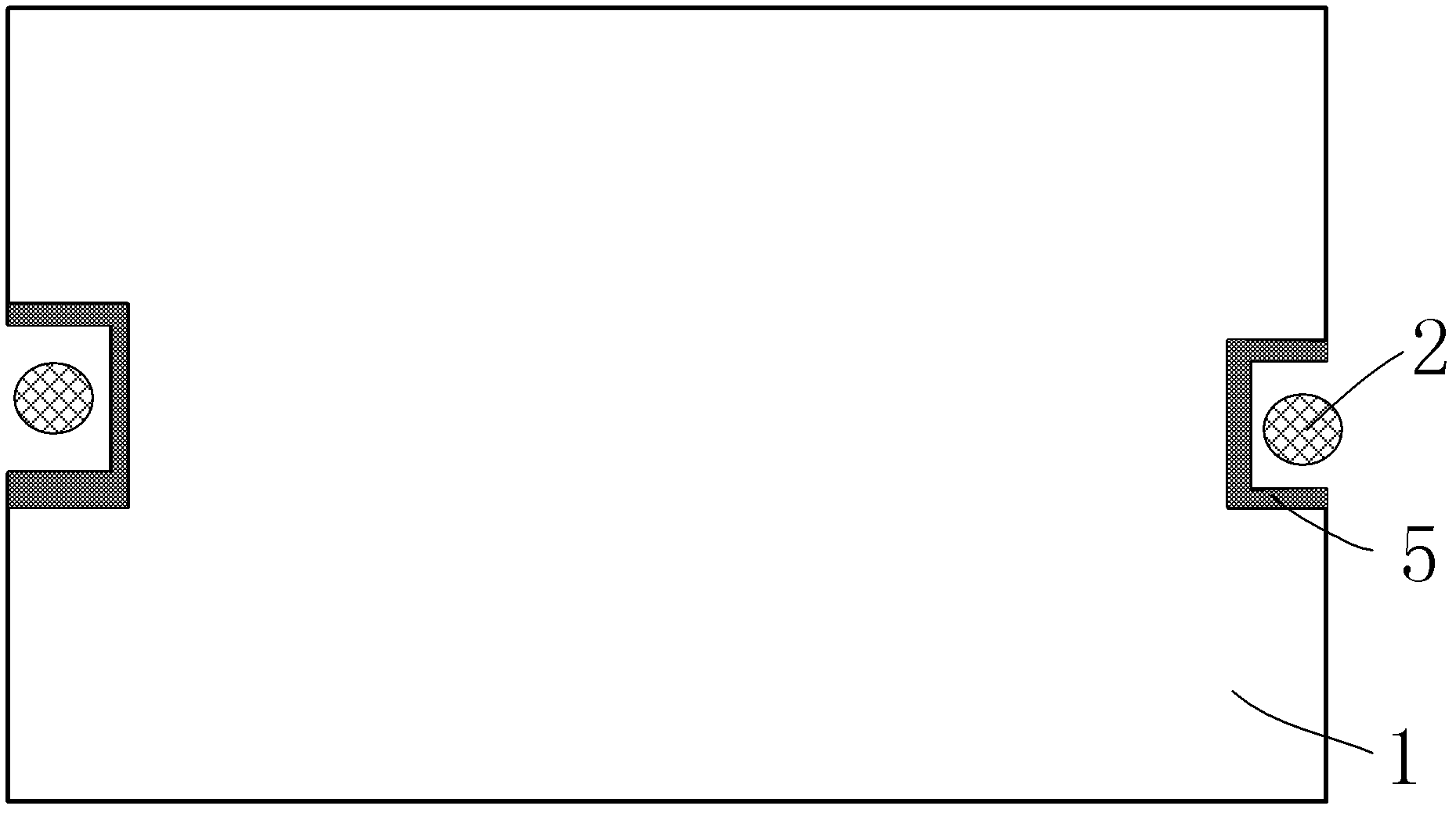

[0029] Such as image 3 As shown, in this embodiment, a buffer pad is attached to the inner surface of the notch 4 with double-sided tape, and the buffer pad can be made of silica gel, rubber or foam materials.

Embodiment 3

[0031] Such as Figure 4 As shown, in this embodiment, a glue dispenser is used to inject transparent elastic colloid into the gap between the notch 4 and the rivet post 2 , so that the buffer member 5 fills up all the gaps and has stronger impact resistance.

[0032] In the present invention, by adding cushioning materials such as silica gel and rubber between the gap 4 of the light guide plate 1 and the rivet post 2, effective buffering can be provided when the impact force is received, and damage caused by direct collision between the light guide plate 1 and the rivet post 2 can be avoided. , the process is simple, the material is cheap, and the low cost can be realized. In addition, when the light guide plate 1 is heated and expanded, the buffer material can also prevent the extrusion damage caused by the direct extrusion of the light guide plate 1 and the rivet post 2; The increase of the distance will easily cause shaking, and the existence of the buffer member 5 can be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com