Membrane wall flue gas waste heat absorption device of vertical boiler chimney

A flue gas waste heat, vertical boiler technology, applied in the direction of climate sustainability, greenhouse gas reduction, lighting and heating equipment, etc., to achieve the effect of large replacement area, considerable energy saving and consumption reduction effect, and good replacement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

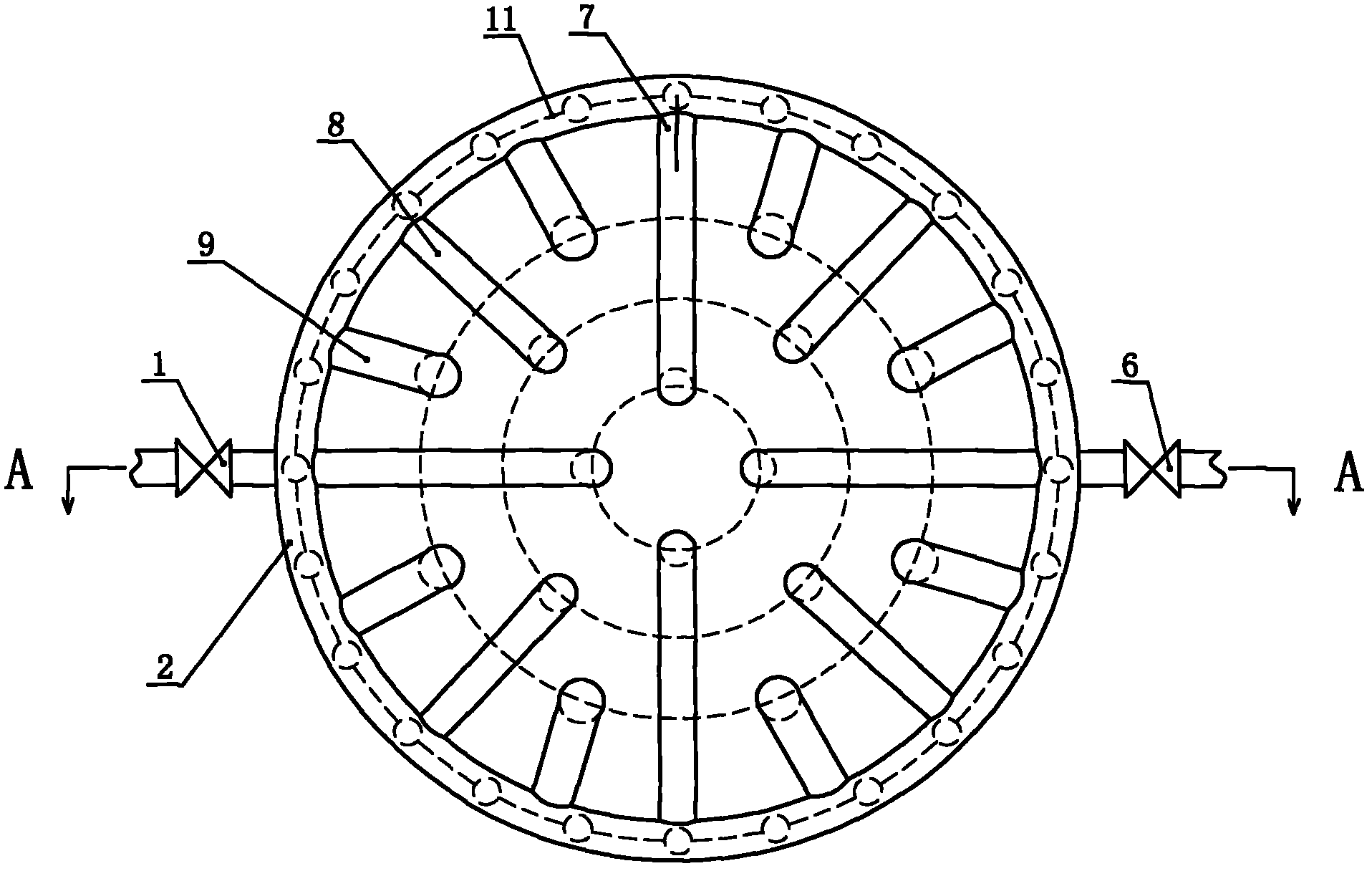

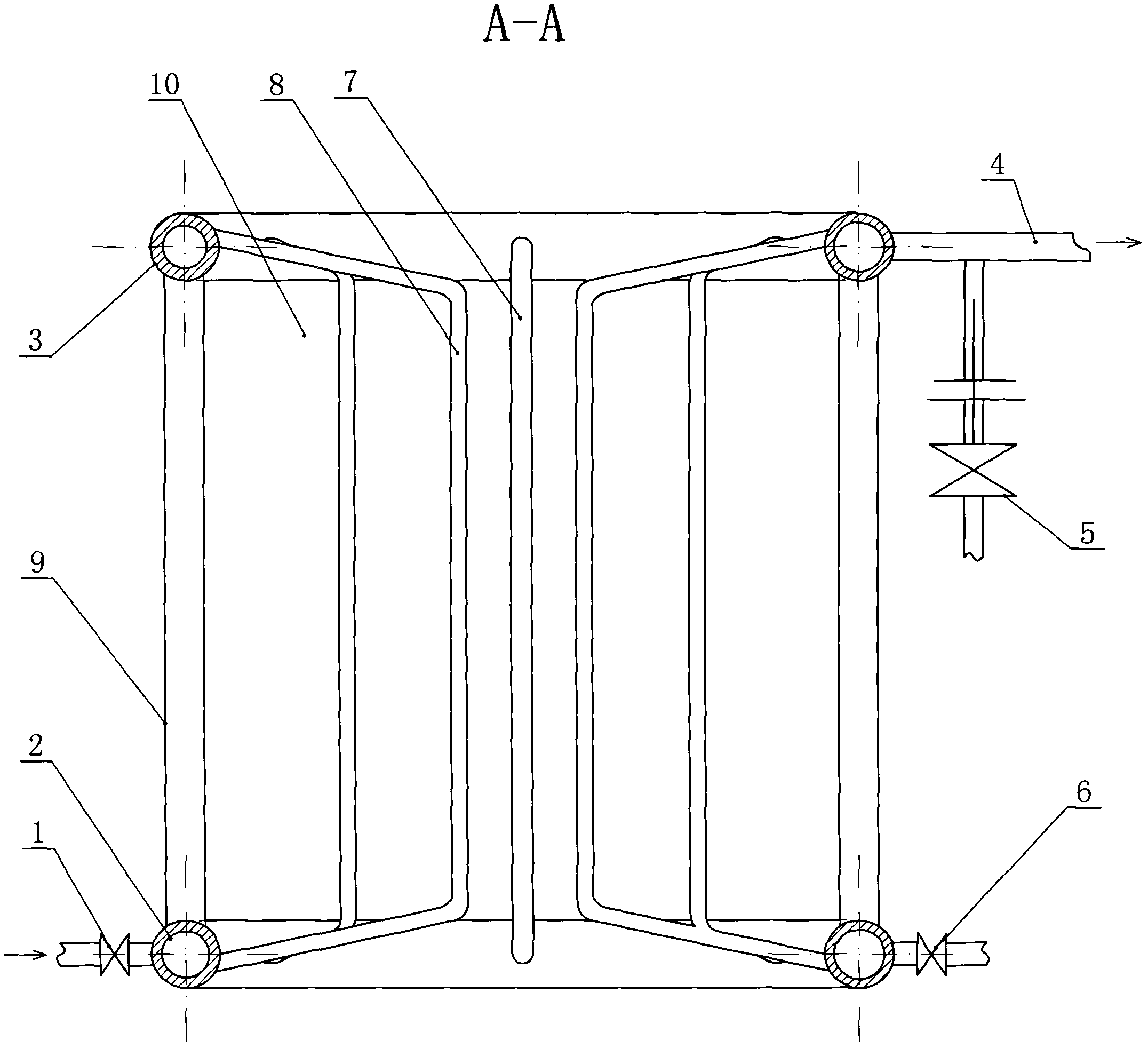

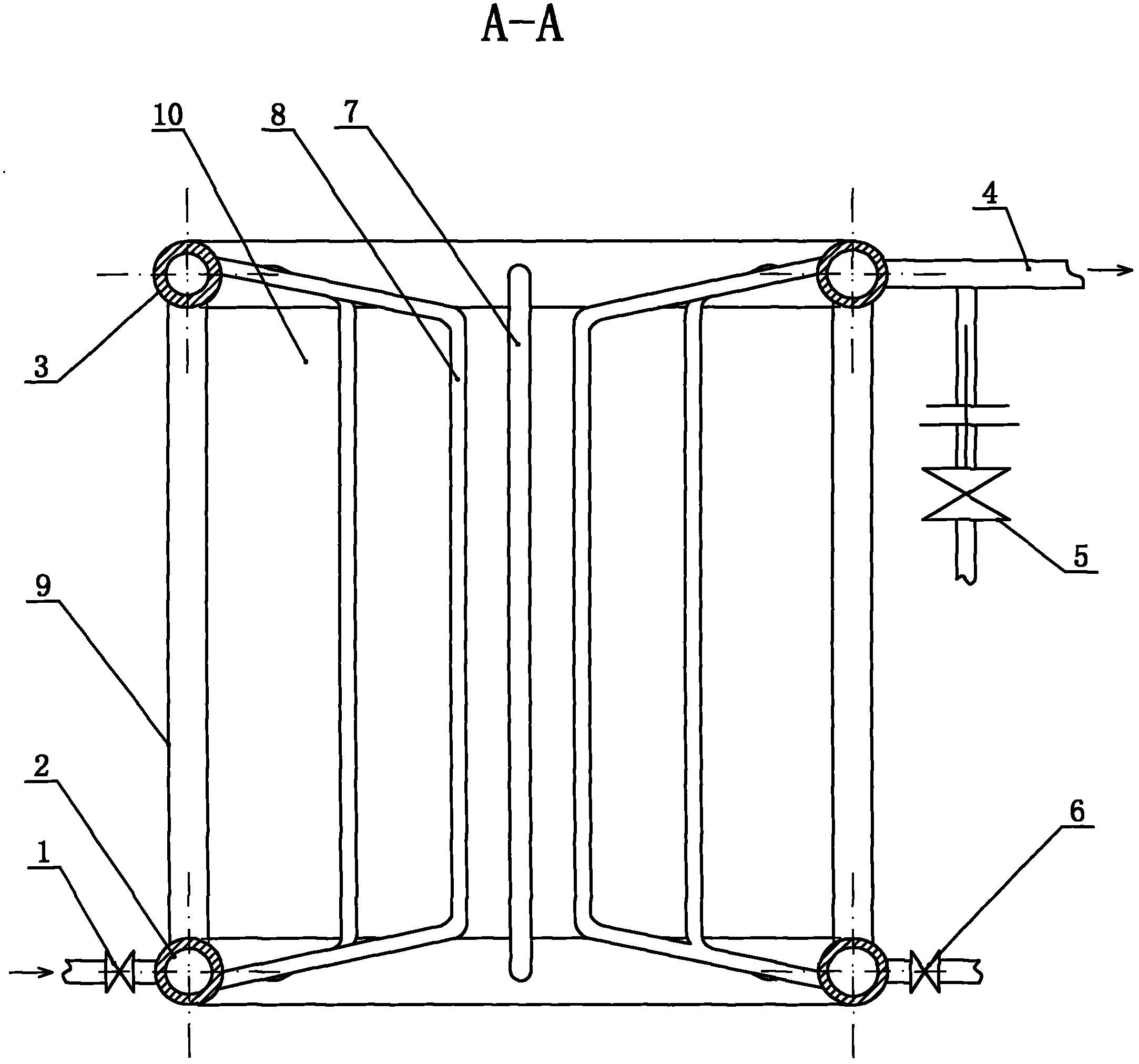

[0015] The structure of the present invention is as figure 1 , 2 As shown, a vertical boiler chimney membrane wall flue gas waste heat absorption device includes an annular lower header 2 and an annular upper header 3, and is characterized in that: the annular lower header 2 is connected with a lower water supply valve 1, and the annular lower header 2 The lower drain valve 6 is connected, the annular lower header 2 and the annular upper header 3 are connected through the membrane wall pipe 9, the annular upper header 3 is connected to the upper water outlet pipe 4, and there is a branch pipe on the upper water outlet pipe 4, and the branch pipe Connected with an upper header emptying valve 5, the annular lower header 2 is connected with the annular upper header 3 through a long-wall threaded pipe 7, and the long-wall threaded pipe 7 is located in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com