Integrated cooker with waste heat recovery function

A waste heat recovery and integrated stove technology, applied in the field of integrated stoves, can solve problems such as self-cleaning and lower work efficiency, and achieve the effects of convenient cleaning, improved efficiency, and improved practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

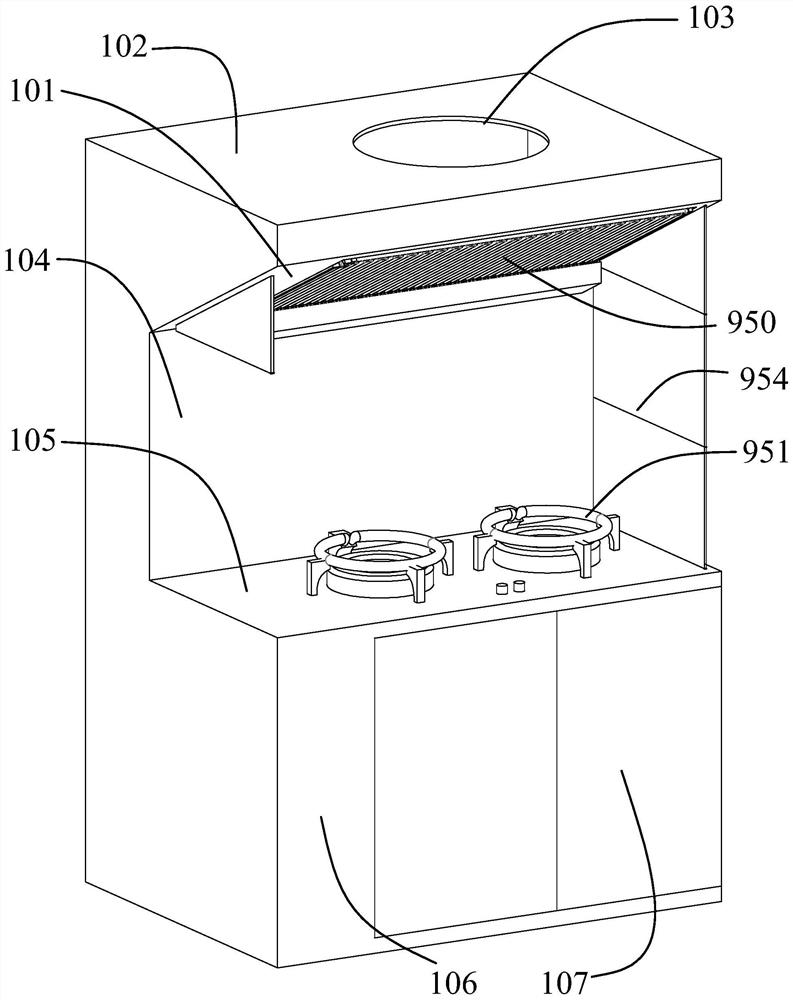

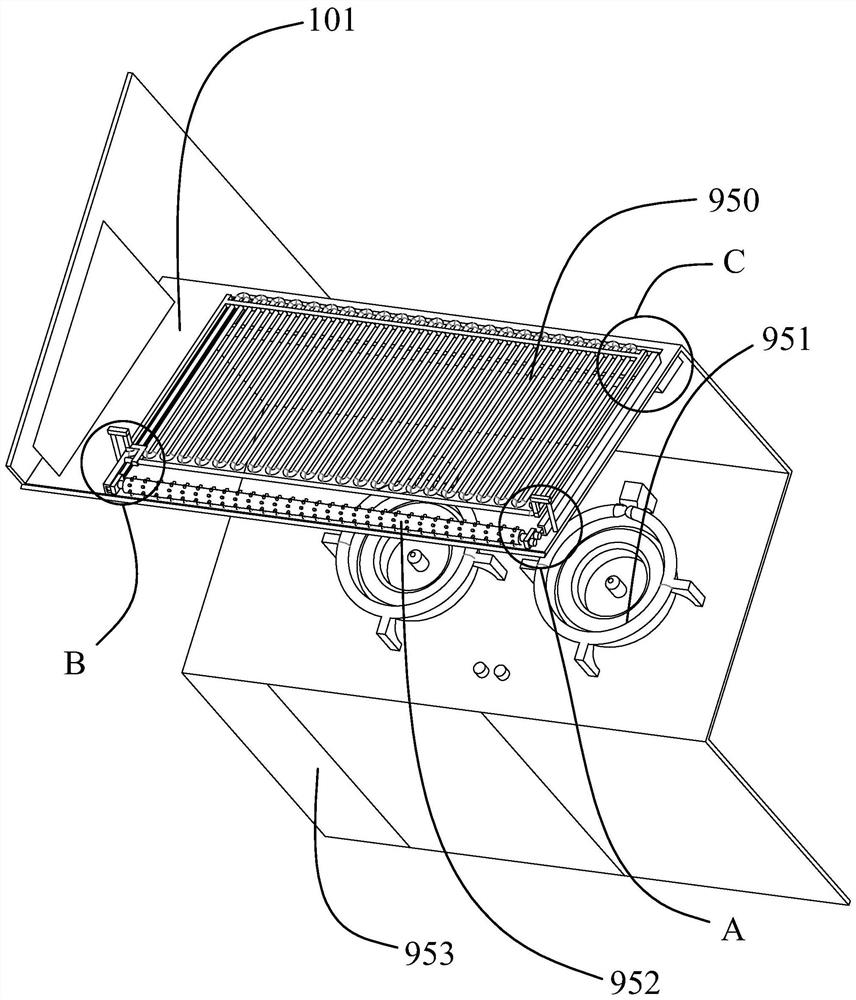

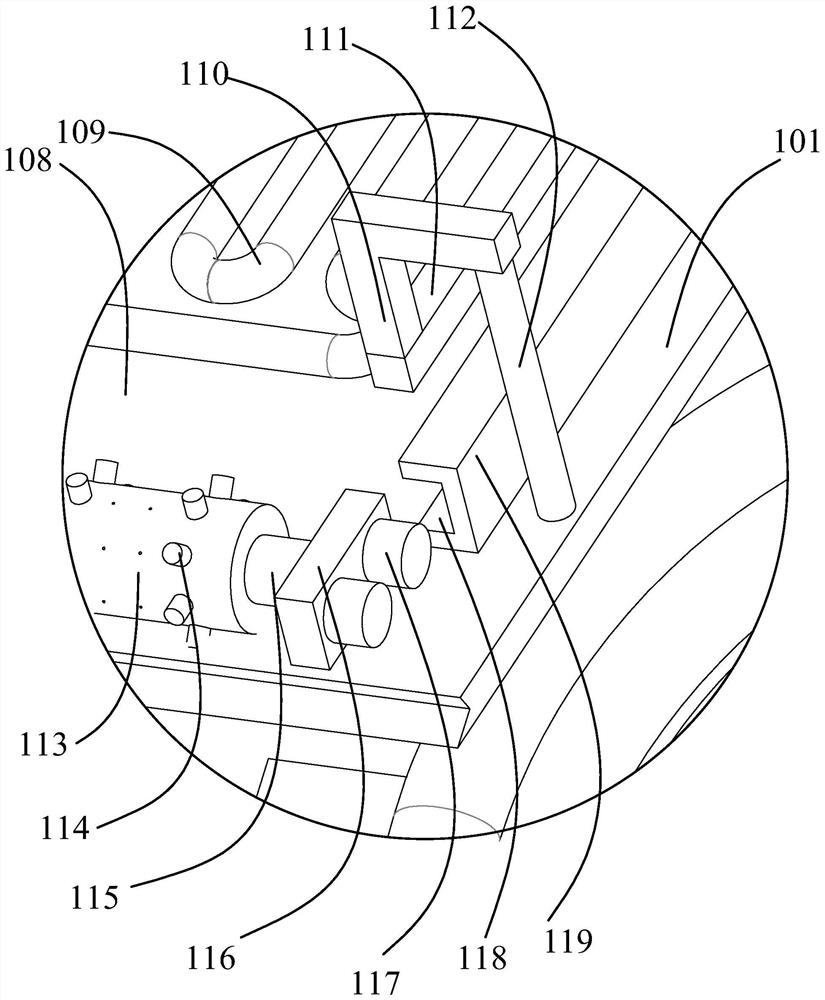

[0033] Such as Figure 1-Figure 9 As shown, the present invention is described in detail. For the convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship are the same. An integrated stove for waste heat recovery according to the present invention includes an integrated frame 104, an operating table 105 is fixed on one side of the integrated frame 104, and a heating pot and a collection device are arranged on the upper side of the operating table 105. The heating device 951 for waste heat utilization, the front plate 106 is fixed on the lower side of the operation table 105, the storage device 953 capable of storing items and circulating hot water is set on the side of the front plate 106, and the top plate 102 is fixed on the upper side of the integrated frame 104, Ventilation holes 103 are opened in the top plate 102, and the ventilation holes 103 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com