Water-proof installation process and construction method for communication optical cable line connector box

A communication optical cable and installation process technology, applied in the direction of optical fiber/cable installation, fiber mechanical structure, etc., can solve the problems of wasting manpower, material and financial resources, water in the optical cable joint box, and fragile optical fibers, etc., to improve the installation quality and improve The effect of work efficiency and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

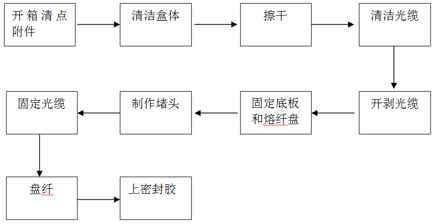

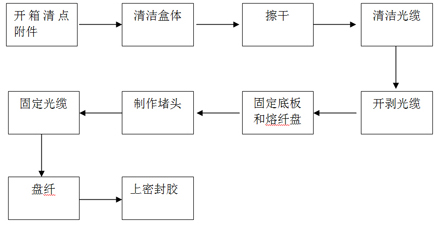

[0034] In the first embodiment, the specific steps of the waterproof installation process and construction method of the communication optical cable line splice box are as follows: figure 1 As shown, its specific implementation steps are:

[0035] Step 1: Open the box and check the accessories;

[0036] When the construction team arrives at the splicing site, they should first check the tools, splicing boxes and their accessories. Pay attention to keep the material dry, clean and free of defects, and replace it immediately if there is a defect;

[0037] The second step: cleaning fit;

[0038] After opening the joint box, use alcohol cotton balls to clean all the upper surfaces of the two box bodies. Note: If the shell is not clean, the waterproof effect of the cement will be greatly reduced. If it is a dirty joint box or a joint box to be reused, it can be rinsed with clean water first;

[0039] The third step: dry;

[0040] All upper plaster surfaces of the two boxes mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com