Method for realizing sag control of color-coating production line by speed regulation

A speed adjustment and production line technology, applied in the field of sag control, can solve the problems of excessive sag fluctuation, unstable sag, and excessive undulation, so as to improve the excessive sag fluctuation, reduce the generation of waste, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

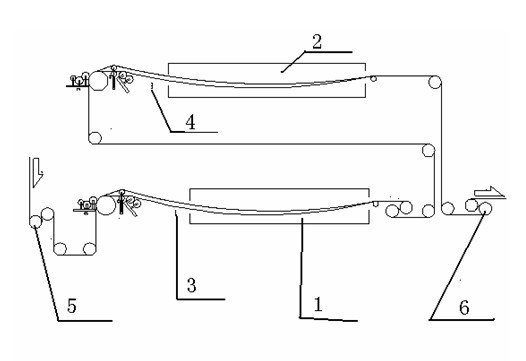

[0012] The technical solution of the present invention will be further described by embodiments in conjunction with the accompanying drawings.

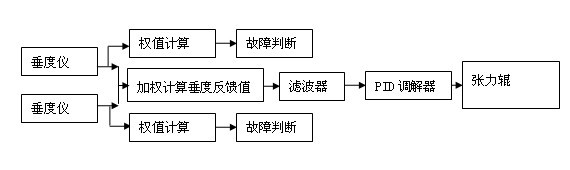

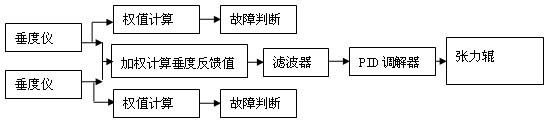

[0013] The method to realize the sag control of the color coating production line through speed adjustment includes the following steps: the data is measured by the sag meter 3 and 4 in front of the curing oven 1, 2 and the weighted average is used as the sag feedback data, and the sag The deviation is introduced into the closed loop control of the speed of the tension rollers 5 and 6 outside the curing furnace, and the speed of the tension roller is adjusted according to the data of the sag feedback, and finally the sag control of the color coating production line is realized.

[0014] The said sag feedback data is filtered by the sag meter before the sag deviation calculation to reduce the sudden change of the on-site sag feedback and make the feedback curve softer; then, by optimizing the proportional coefficient in the sag deviation PID...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com