Vorrichtung, insbesondere am vorbau eines kraftfahrzeuges

A car body and end-side technology, which is applied to the connection between superstructure subassemblies, vehicle components, superstructure, etc., can solve the problem of increasing installation costs, inability to ensure that the corners of the steel plate are really attached, and the strength cannot be impressive Satisfaction and other issues to achieve the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

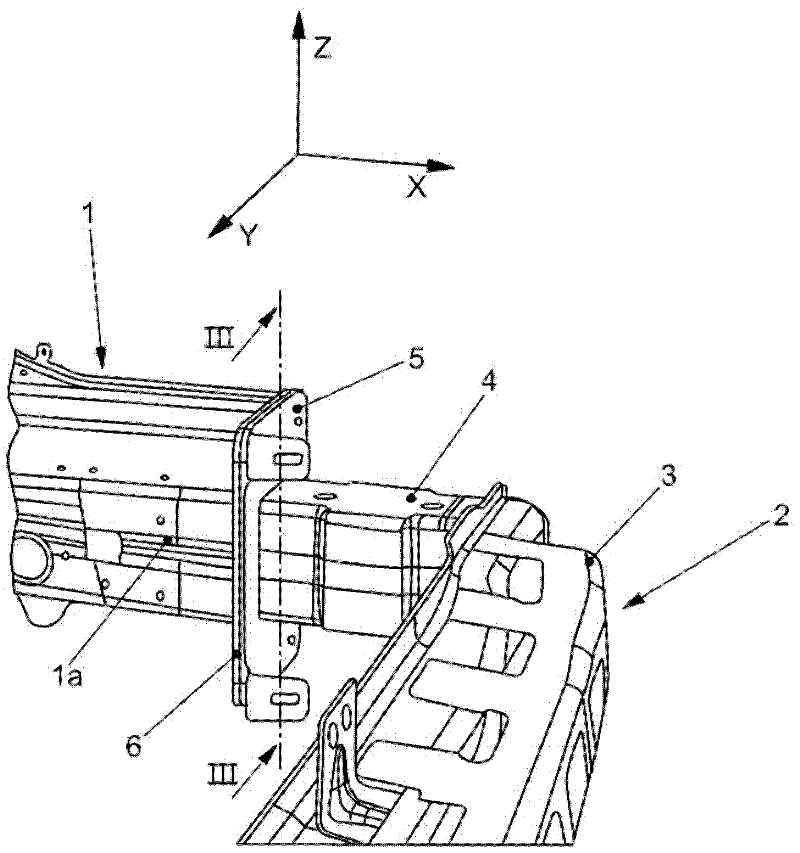

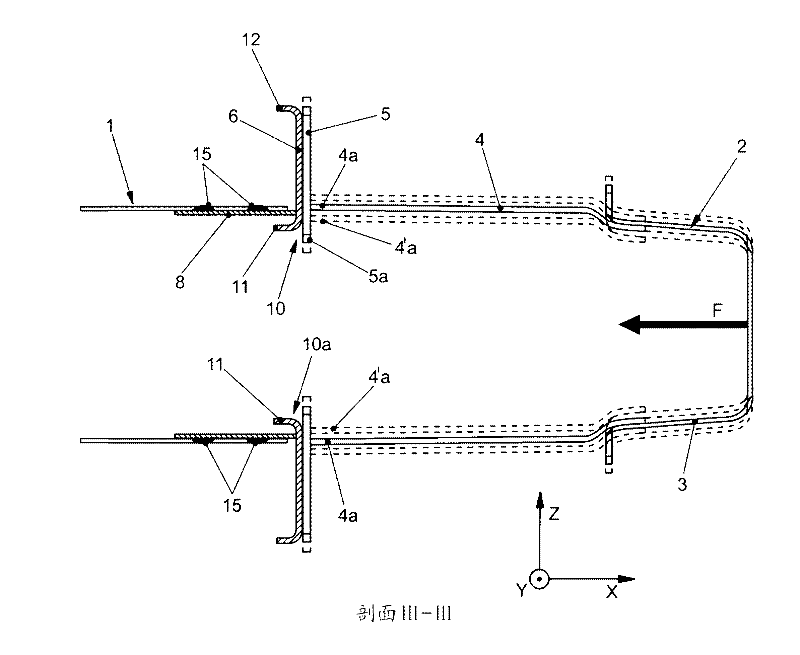

[0028] figure 1 Shown is the front end region of a longitudinal member 1 with a hollow profile and a cross member 2 fastened to the longitudinal member 1 of the front end of the vehicle body, not shown further, with two parallel to each other and extending in the longitudinal direction of the vehicle (X direction) The longitudinal beam 1 and the cross beam 2 connecting the two longitudinal beams 1. The cross member 2 supports, in a known manner, the front module components of the motor vehicle body, which are dimensionally precisely connected to the adjoining body components. This requires that the beams 2 be dimensionally accurately configured with the longitudinal beams 1 in the Y-direction (transverse), Z-direction (vertical) and X-direction.

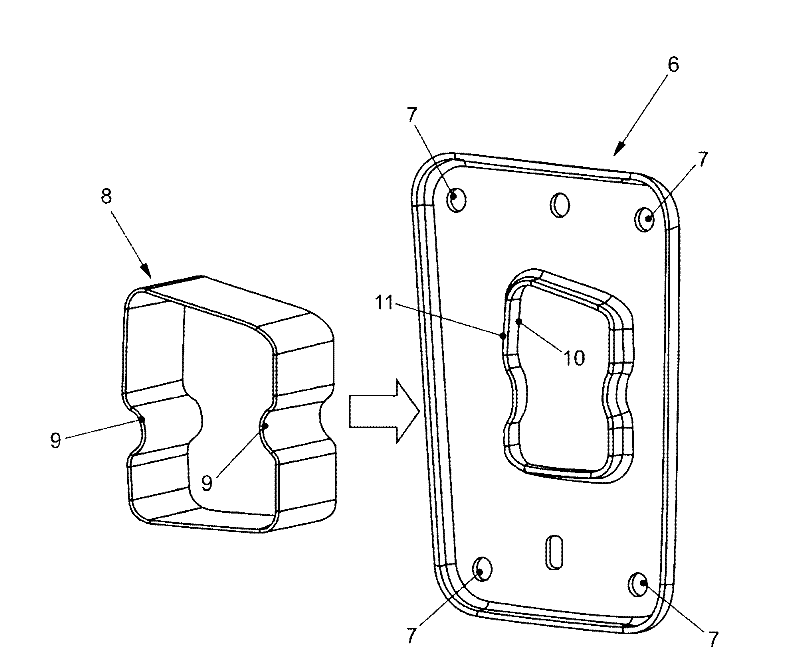

[0029]The cross member 2 has a front deformation element 3 and a side deformation element 4 with a hollow profile oriented in the longitudinal direction of the vehicle. On the deformation element 4 ( figure 1 Only the left-hand de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com