Filament bundle fiber chemical modification production device

A production device and a technology for chemical modification, applied in the field of functional fiber preparation, can solve the problems of unsuitability for chemical modification of filament bundles, poor uniformity, etc., achieve good product uniformity, improve production efficiency, and realize continuous industrial production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0019] The superabsorbent fiber is prepared by using the production device of the present invention.

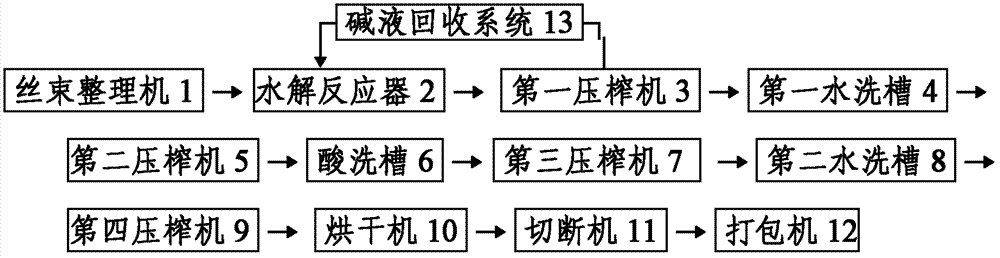

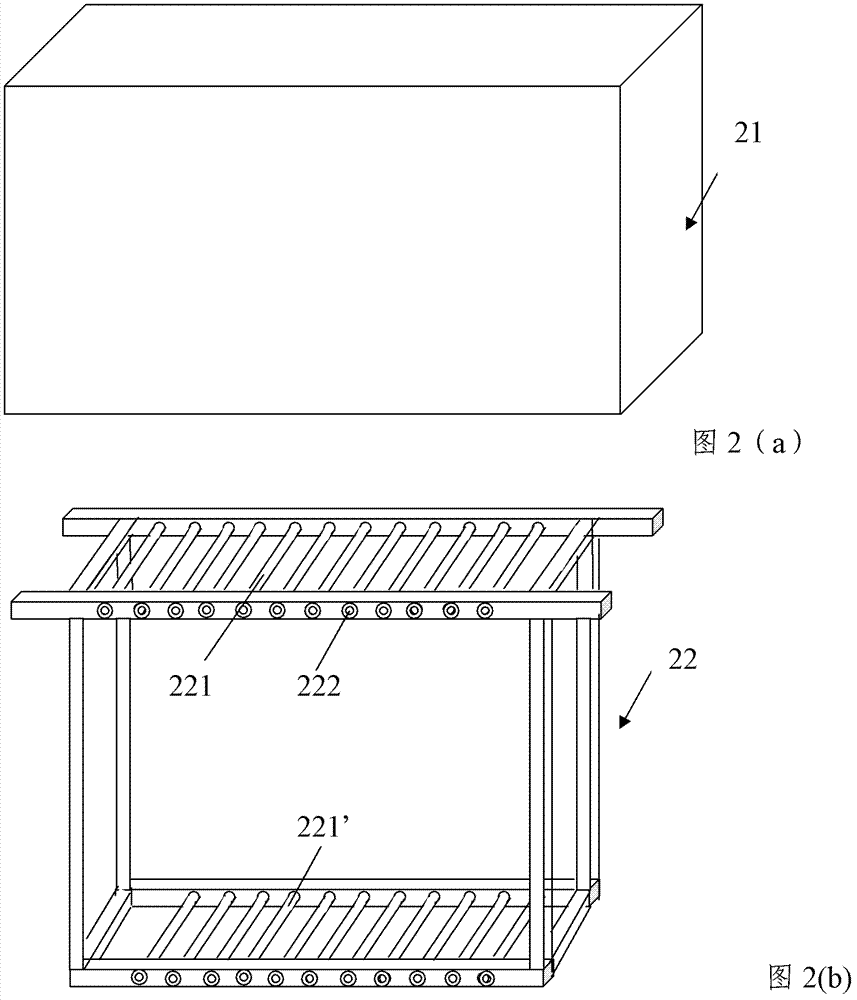

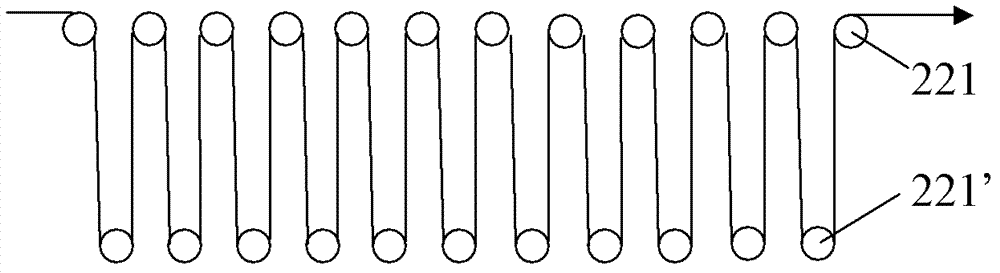

[0020] The long filament bundles of polyacrylonitrile semi-finished fibers are used as raw filaments, and after being sorted by the tow finishing machine 1, the filament bundle fibers with evenly distributed tension enter the hydrolysis reactor 2, and the filament bundles to be hydrolyzed reciprocate in the tow The 21 upper godet rollers 221 and the 20 lower godet rollers 221' of the frame 22 are reciprocally wound up and down to prolong the reaction time reasonably; after the temperature in the hydrolysis reactor 2 is 90-95°C, the NaOH concentration is 150410g / After reacting in the bath liquid of L for 50-60min, then pass through the first squeezer 3, the first washing tank 4, the second squeezing machine 5, the pickling tank 6, the third squeezing machine 7, the second washing tank 8, the After four squeezers 9, dryers 10, cutters 11 and balers 12, the product high water-a...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap