Polymer electrolyte for dye-sensitized solar cells and a fabrication method of dye-sensitized solar cells using the polymer electrolyte

A technology of solar cells and dye sensitization, applied in the field of polymer electrolytes for dye-sensitized solar cells and using it to manufacture dye-sensitized solar cell modules, can solve the problems of no commercially available products and little significance, and achieve Effect of prevention of electrolyte leakage and high solar conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

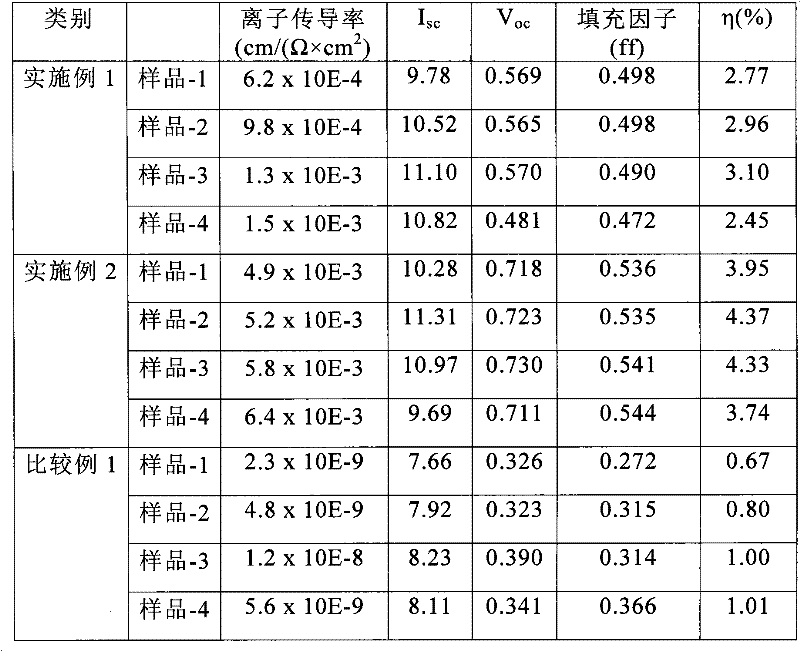

Examples

Embodiment 1

[0068] (1) Manufacture of working electrode

[0069] After preparing the FTO glass substrate, the titanium dioxide (TiO 2 ) coating composition coated on top of the transparent conductive oxide layer of the substrate, followed by heat treatment at 520° C. for 40 minutes to achieve contact and filling between nanometer-sized metal oxides, thereby producing a thickness of about 7μm nano-oxide layer. Use 3M Scotch Magic Tape as a spacer to adjust thickness. Thereafter, the same coating composition was coated on top of the nano-oxide layer by the same method, followed by heat treatment at 520° C. for 40 minutes, thereby manufacturing a nano-oxide layer with a thickness of about 15 μm. Then, a dye solution was prepared using N-719 dye from Solaronix and ethanol, wherein the substrate formed with the nano-oxide layer thereon was immersed for 48 hours, and then the substrate was dried to allow the nano-sized metal oxide to absorb the dye, Thus, a negative electrode is produced. ...

Embodiment 2

[0084]Using the same method as in Example 1, the difference is that 100 parts by weight of bisphenol A liquid epoxy resin (YD 128 from Toto Kasei Co., Ltd.) is used instead of cresol novolac epoxy in the preparation of the polymer electrolyte resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com