Method for covering outer surface of large cylinder and covering machine thereof

A cylindrical and outer cylindrical technology, which is applied in the field of wrapping packaging materials on the outer surface of large cylinders, can solve problems such as equipment failures, achieve the effects of improving adaptability, ensuring pasting quality, and improving packaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

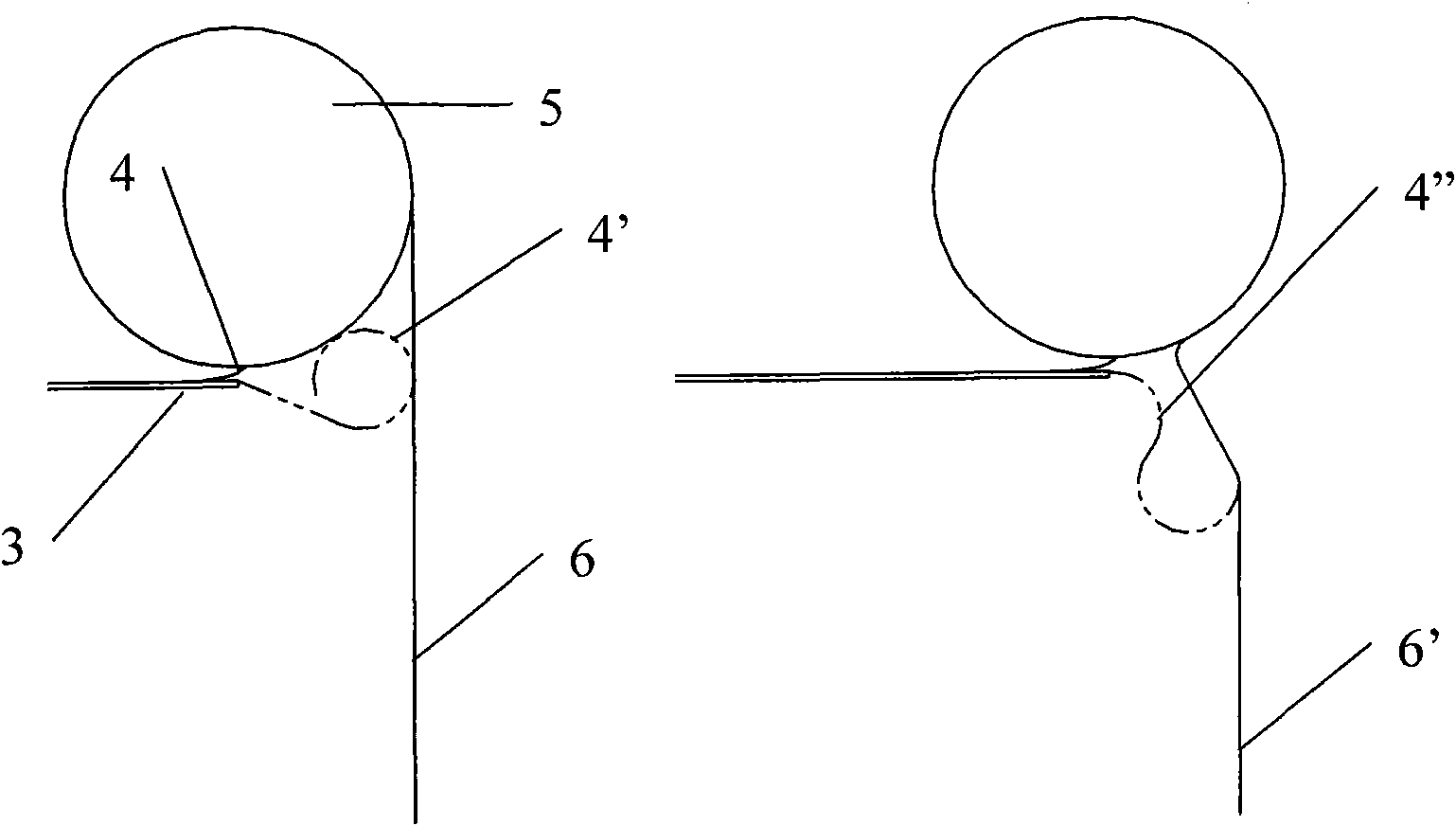

[0027] Figure 1 to Figure 5 A specific implementation of the described principle is as Image 6 with Figure 7 shown.

[0028] The fixing methods of roller blinds can be binding, riveting and gluing. The best way is to use sticky buttons, glue the back of the hard buckle piece of sticky buckle on the outer circle of the roll, and sew the soft piece of sticky buckle on the roller blind. superior. It is advisable to stick the whole week to get a uniform thickness and easy to roll.

[0029] exist Image 6 Among them, 16 is a feeder, and the frame (9) is the basis for connecting and fixing other functional components. The frame is not the protection content of the present invention, so it is not discussed in detail. The frame of the present invention is connected with the feeder. What is the structure of the frame, in short, the frame is connected to the foundation. In the figure, the cylinder (13) is the executive element that drives the paper-holding manipulator of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com