Ground-heating thermal insulation layer

An insulation layer and floor heating technology, applied in insulation and building components, etc., can solve the problems of heat loss of insulation boards, reduce insulation efficiency, and complicated fixing methods, so as to reduce material costs, improve insulation efficiency, improve mechanical strength and service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

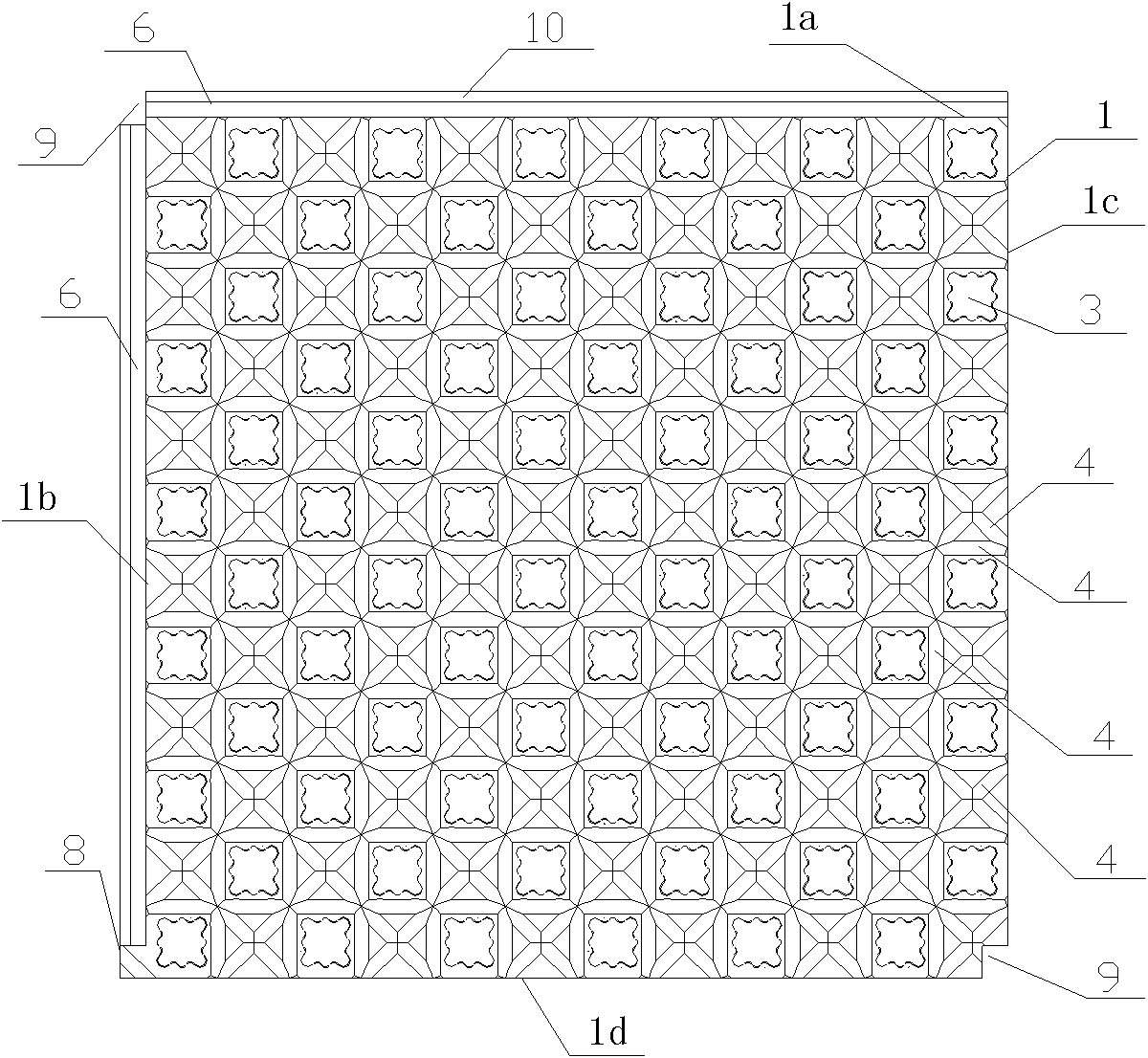

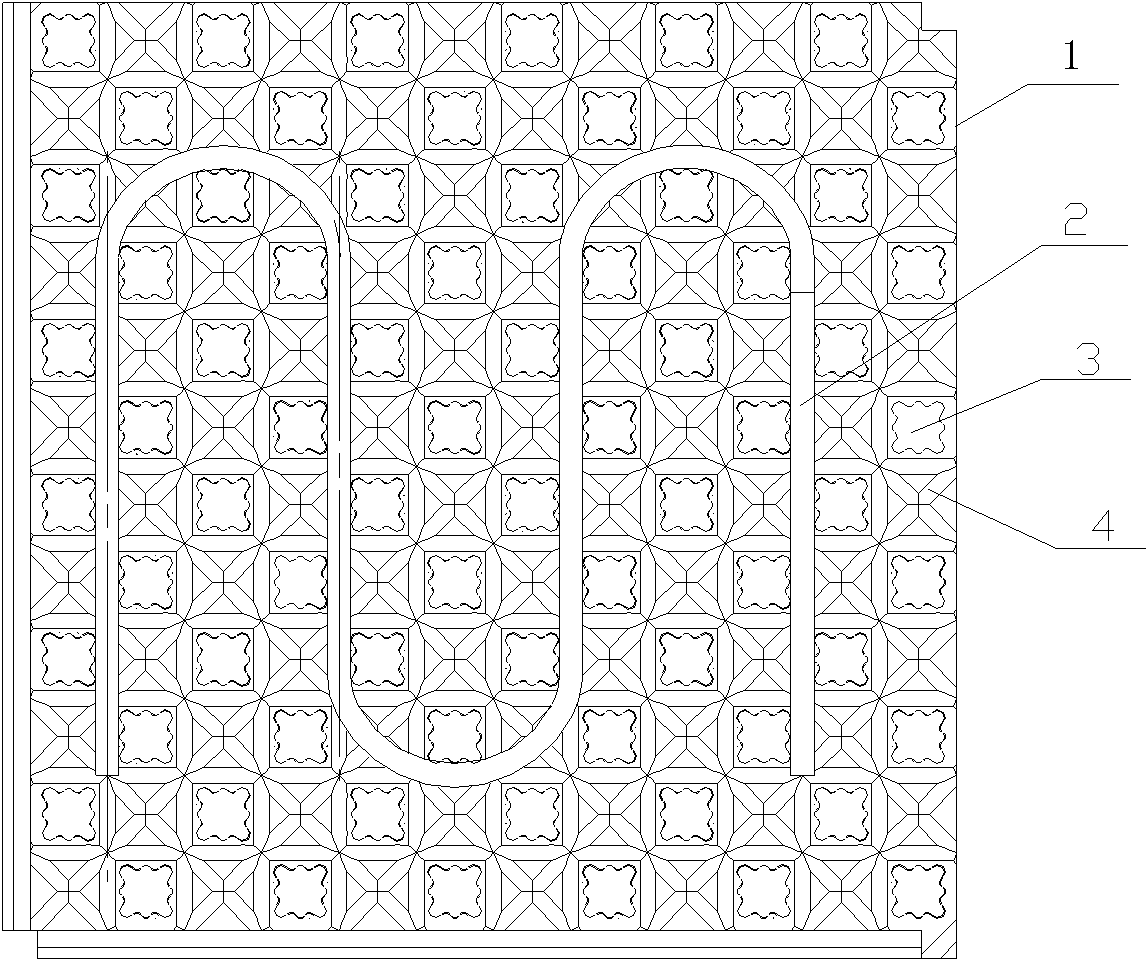

[0021] Such as Figure 1 to Figure 4 As shown, the floor heating insulation layer is first laid on the indoor cement floor, the floor heating pipeline 2 is laid on the floor heating insulation layer, and then a layer of cement is poured on it, and the indoor floor or tiles are laid on the cement.

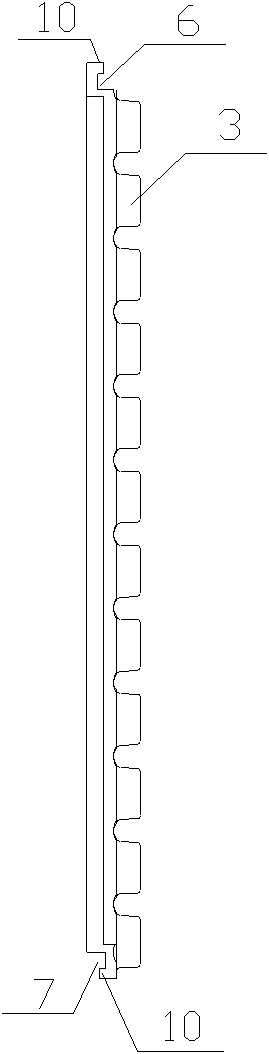

[0022] Floor heating insulation layer comprises thermal insulation board 1, and the material selection EPS (expanded polystyrene) of thermal insulation board 1, for easy installation, the shape of thermal insulation board 1 is generally a square.

[0023] Several protrusions 3 are arranged on the front of the insulation board 1, the protrusions 3 are regularly arranged on the insulation board 1, the protrusions 3 and the insulation board 1 are integrally foamed, and the protrusions 3 can improve the mechanical strength of the insulation board 1, The carrying capacity is also greatly improved. Such as figure 2 As shown, the floor heating pipe 1 is directly stuck between the protru...

Embodiment 2

[0033] As shown in Figure 6, several second grooves 5 are arranged on the first groove 4, the second grooves 5 are arranged at the intersection of each first groove 4, and the bottom surface of the second groove 5 is slightly lower On the bottom surface of the first groove 4 next to it, the width of the second groove 5 is slightly larger than the width of the first groove 4, and the second groove 5 can be polygonal, square or circular. shaped structure. After pouring cement on the heating pipe 2, the cement in the second groove 5 can flow to the bottom of the heating pipe 2, that is, the whole heating pipe 2 is surrounded, and after the cement is solidified, the cement here forms a pipe. The function of the clip makes the floor heating pipeline 2 more firmly fixed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com