Full automatic edge bar assembly equipment for square vehicular air conditioner filter

A technology for automotive air conditioners and assembly equipment, applied in the direction of mechanical equipment, connecting components, etc., can solve problems such as difficult to achieve unified standards, unfavorable management and development, and reduced production efficiency, and achieve good performance consistency, firm and reliable welt, and Side action and position accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

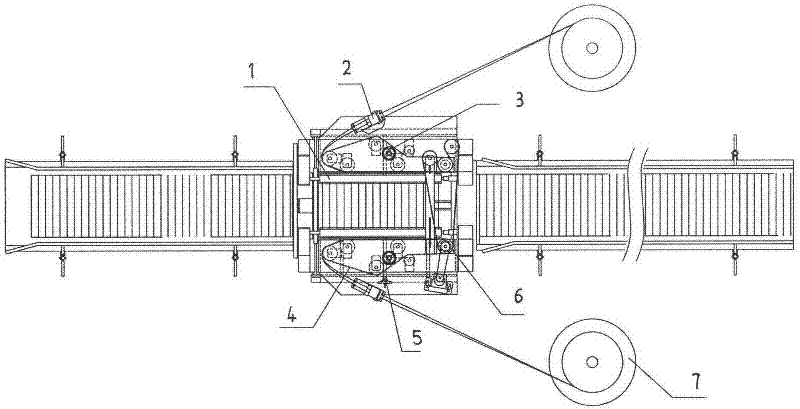

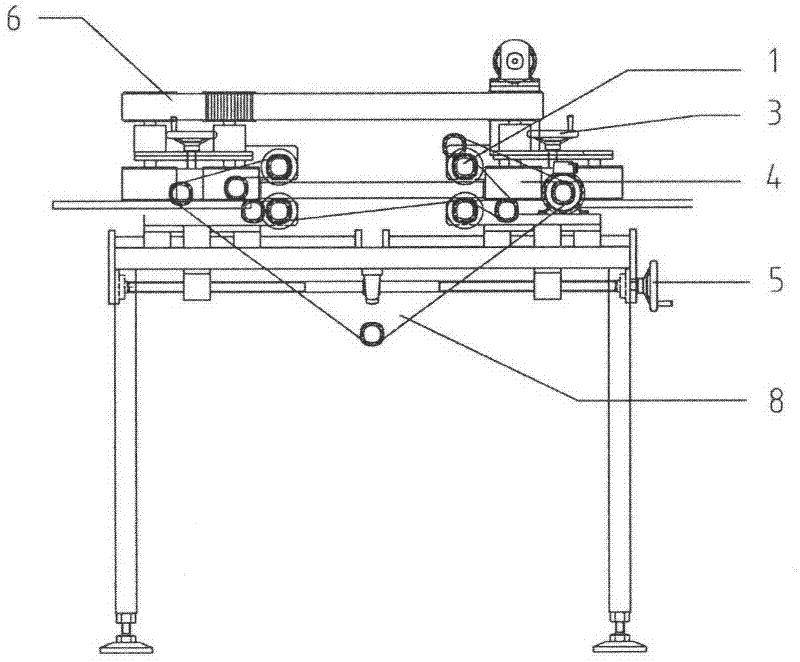

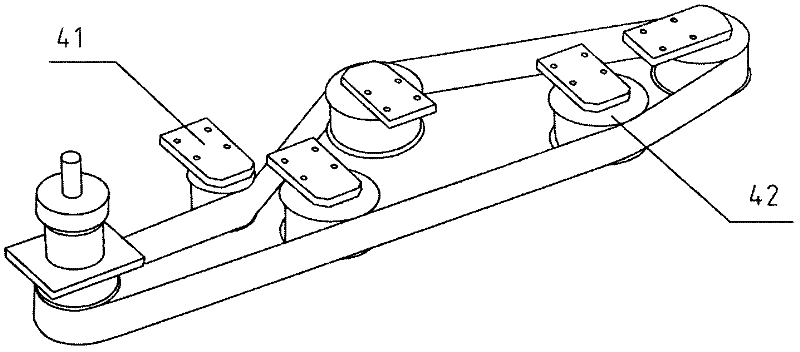

[0020] 1-Separation wheel device, 3-Blanking height adjustment mechanism, 4-Blanking synchronous belt mechanism, 5-Opening and closing adjustment mechanism, 6-Welt transmission device, 8-Separation wheel transmission group, 41-Tension wheel assembly , 42-drive wheel assembly

[0021] Such as figure 1 As shown, the fully automatic edge strip assembly equipment includes a separator wheel device 1, an edge-holding timing belt mechanism 4, an edge-holding height adjustment mechanism 3, and an opening and closing adjustment mechanism 5. There are 4 dividing wheels in total, which are distributed on the upper, lower, left, and right positions of the main body of the filter core, and the dividing wheels on the diagonal are the same, and all rotate outward. The thread directions of the two sets of dividing wheels in the separating wheel device are opposite, and what is adopted is a trapezoidal thread, and the thread pitch is the distance between adjacent folds of the filter. One end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com