Five-dimensional force sensor

A sensor and five-dimensional force technology, which is applied in the direction of instruments, measuring forces, and measuring devices, can solve problems such as unsuitable for popularization and application and manufacturing difficulties, and achieve the effects of solving the coupling problem between dimensions, making it easy to manufacture, and improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

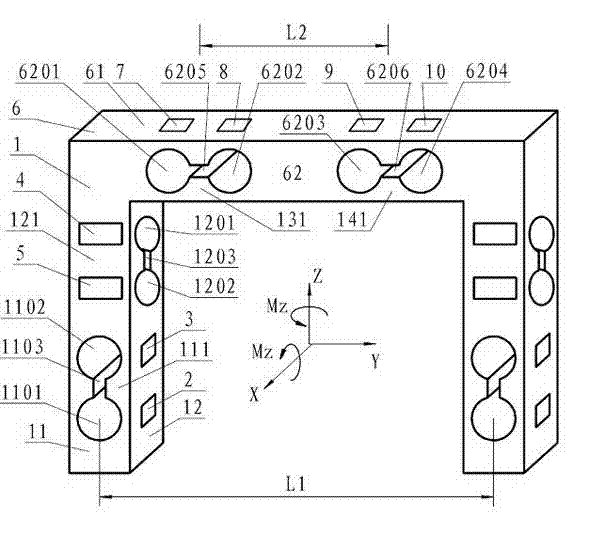

[0013] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0014] like figure 1 As shown, a five-dimensional force sensor of the present invention includes two two-dimensional force sensors and a beam 6 . Each two-dimensional force sensor includes a rectangular section beam 1 . The rectangular section beam 1 comprises opposite top and bottom faces, opposite first and third sides 11 , and opposite second and fourth sides 12 . A first through hole 1101 and a second through hole 1102 arranged up and down are opened on the first side 11 and the third side. The axes of the first through hole 1101 and the second through hole 1102 are parallel to each other and located in the same vertical plane. A first through groove 1103 is formed between the first through hole 1101 and the second through hole 1102 . The first through groove 1103 communicates with the first through hole 1101 and the second through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com