Arc-shaped light emitting diode (LED) display screen and manufacturing and installation method thereof

A technology of LED display screen and installation method, which is applied to identification devices, instruments, etc., which can solve the problems of high processing cost, high processing accuracy requirements, and inability to standardize, and achieve low processing accuracy requirements, good display effect, and easy processing and manufacturing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

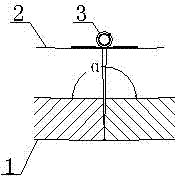

[0032] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

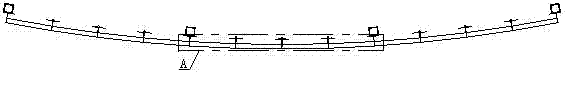

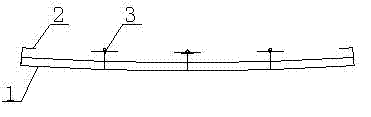

[0033] like Figure 1 to Figure 3 As shown, the single-row box body 2 can be realized with one module 1 as the width, and can also be realized with a plurality of modules 1 as the width, and the modules 1 are embedded or fastened in the substantially flat surface of the single-row box body 2 . straight mounting plane.

[0034] This technology realizes the entire project by splicing at least two single-row boxes 2 into a box unit A, so as to achieve an approximate circular arc on the surface of a single box unit A with one (or more) modules 1 as a unit. arc effect.

[0035] Specific steps:

[0036] The first step: first process the single-row box 2 with a single module (or multiple modules) as the width;

[0037] The second step: process several splicing shafts 3;

[0038] The third step: according to the radius R of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com