Method for washing and purifying autologous oxide on surface of GaAs (gallium arsenide) and depositing Al2O3 medium

一种砷化镓、氧化物的技术,应用在使用液体的清洁方法、清洁方法和用具、化学仪器和方法等方向,能够解决栅极泄漏电流上升、栅极泄漏电流增加、器件性能退化等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

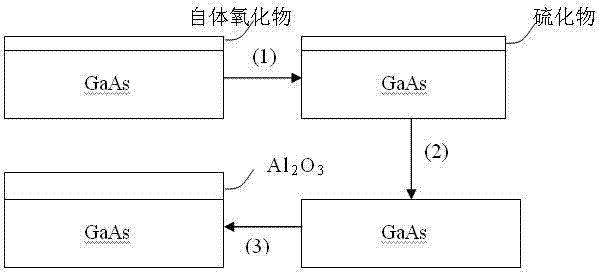

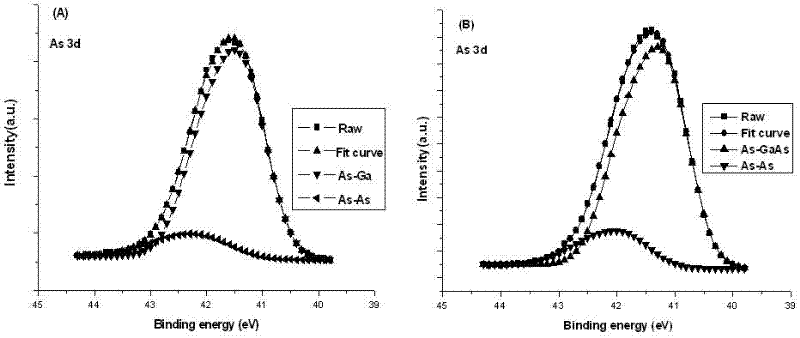

[0051] In the experiment, Si-doped n-type (100) oriented GaAs samples were used, and the doping concentration was about 1.0×10 17 cm -3 . After the GaAs sample was cleaved into small pieces, it was placed in trichlorethylene, acetone, alcohol and deionized water for 5 minutes for ultrasonic cleaning to remove surface grease and organic matter. Then put the GaAs sample in a dilute HF solution with a concentration of 2%, rinse the excess HF solution with deionized water after cleaning for 2 minutes, this step is to clean the oxides on the surface of GaAs. Then soak in 10% ammonia water for 5 minutes, and use the alkali to react with the GaAs autogenous oxide to remove it. In addition, this step can also neutralize the previous HF solution.

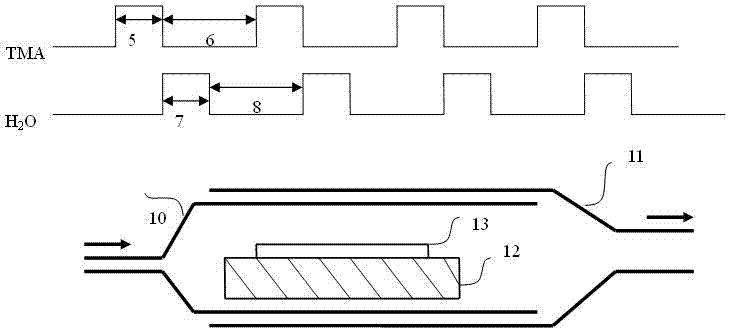

[0052] With 2g of CH 3 CSNH 2 , 4ml of absolute ethanol and 1ml of ammonia water to prepare a mixed solution, take out the GaAs sample with clean tweezers, and immediately put it into the mixed solution for passivation for 10 minutes, re...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap