Closed five-face screen roller tobacco stalk separator

A sorting machine and sieve rolling technology, applied in tobacco, sieve, solid separation and other directions, to achieve the effect of improving yield, reducing maintenance cost, labor intensity of workers, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

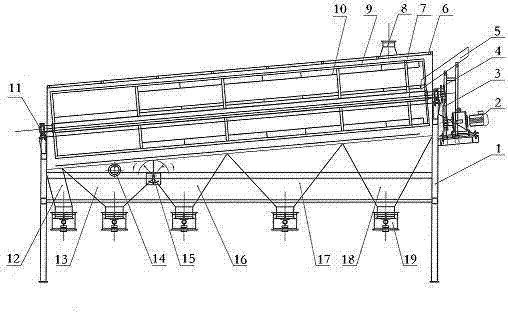

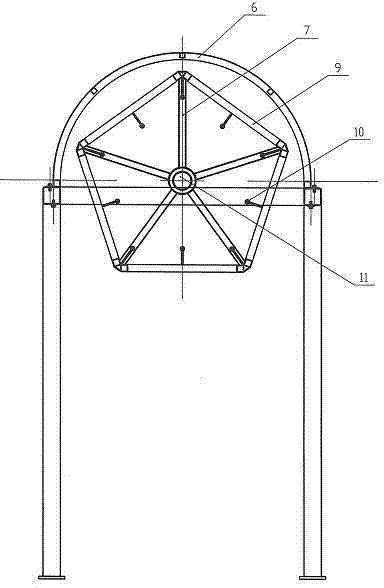

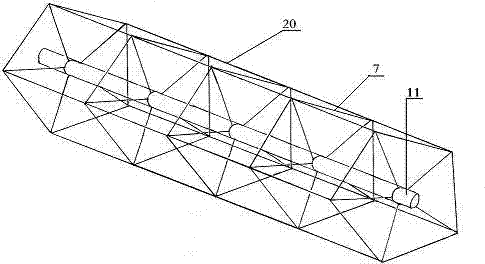

[0025] The technical solution will be described in detail below in conjunction with the accompanying drawings as an embodiment.

[0026] refer to figure 1 , 2 , 3, 4, the frame 1 is fixed by four supporting feet and connecting rods in the vertical and horizontal directions. The upper part is equipped with a sieve roll, and the lower part is equipped with four storage bins and a turning bin. A platform for fixing the motor reducer 2 is welded on the outer side of the high-end, and there is a fixing frame for installing the tobacco stem inlet chute 5 and the sprocket assembly 3 on the platform; a bearing with seat 4 is respectively fixed at the center of the cross bar above the high-end and low-end of the frame , the sieve roll is composed of a sieve roll frame and a screen plate fixed on the sieve roll frame. For the positions of the five corners of the five skeletons, use five equal-length support rods 7 to weld them together with the sieve rollers; The ribs 20 on each rib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com