Degasser

A degasser and degassing technology, applied in the field of degasser, can solve the problems of damage to motor bearings and degassing disc bearings, difficult maintenance, and difficult work for employees, so as to ensure long-term operation and reduce labor intensity. , the effect of eliminating safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

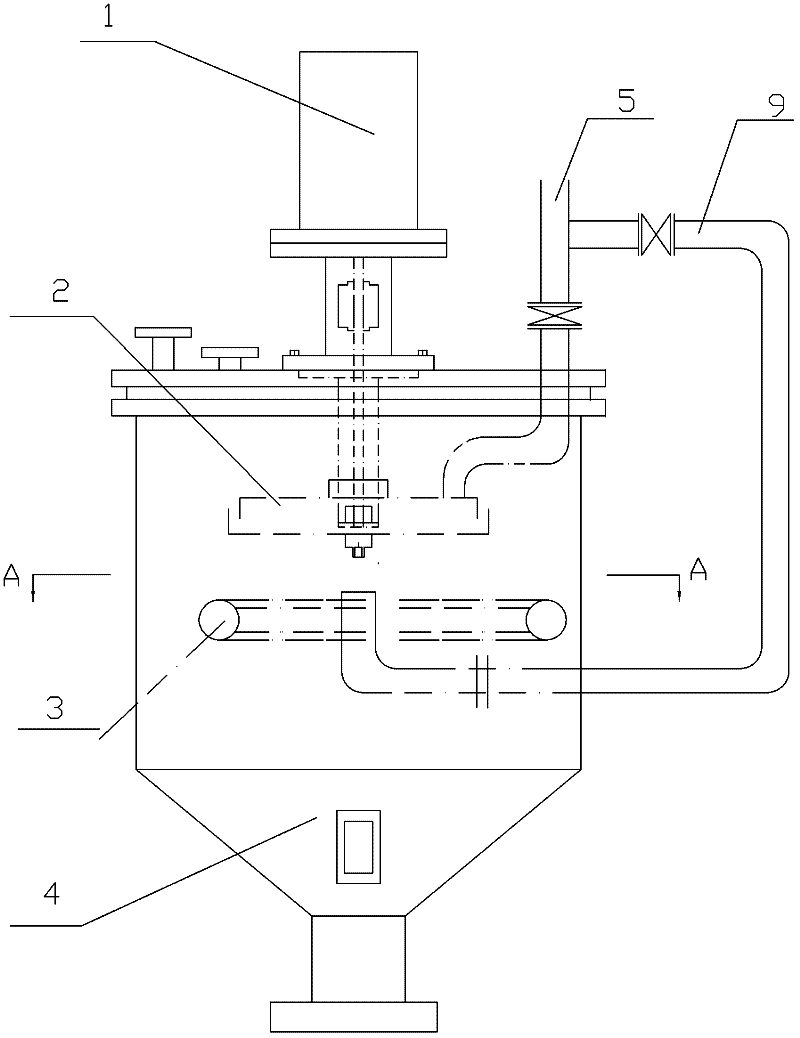

[0020] Refer to attached Figure 1-2 :

[0021] The degasser consists of a motor 1, a degassing spinner 2, a degasser distributor 3, a degasser body 4, a feed inlet 5, a discharge coil 6, a discharge hole 7, a bracket 8 and a feed pipe 9 The upper part of the degasser body 4 is cylindrical, and the lower part is a hopper-shaped outlet. The vacuum pump, motor 1 and feed inlet 5 are installed and fixed above the upper cover of the cylindrical degasser body 4. The motor 1 is connected to the The degassing spinner 2 is connected, and the degassing distributor 3 is arranged in the middle below the degassing spinner 2, and is opposite to the degassing spinner 2. The degassing distributor 3 is connected to the top of the degasser body 4 through the feed pipe 9. The feeding port 5 is connected.

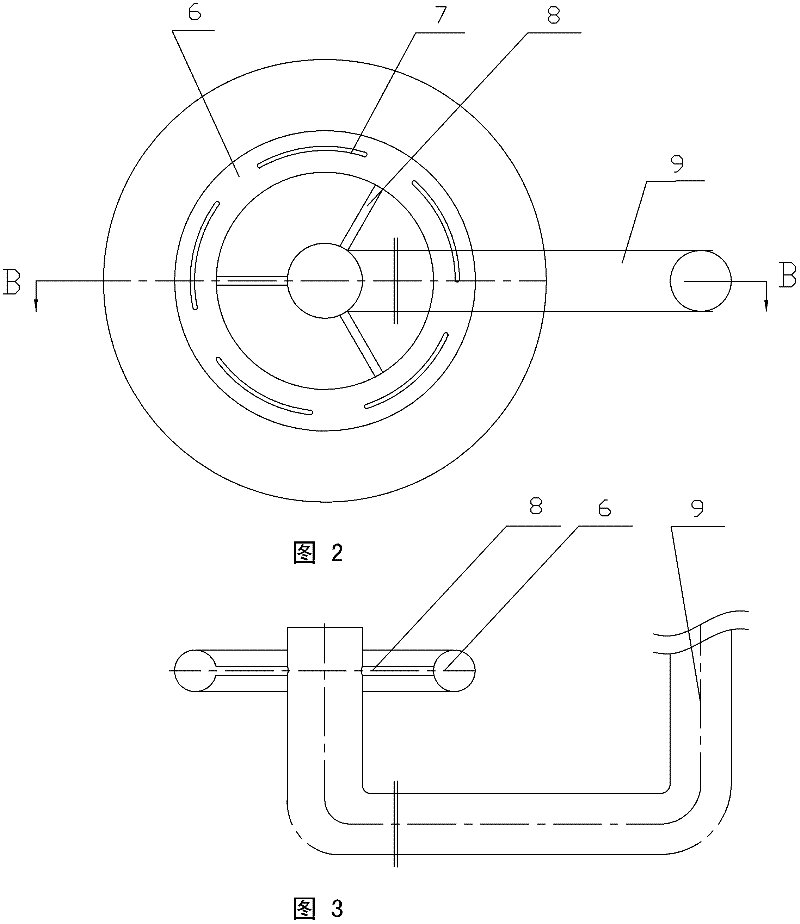

[0022] Refer to attached Figure 2-3 :

[0023] The degassing distributor 3 includes a feed pipe 9, a discharge coil 6, a plurality of discharge holes 7 provided on the discharge coil 6, ...

Embodiment 2

[0029] A degassing distributor 3 is set in the degasser body 4, the lower end of the feed pipe 9 is connected to the degassing distributor 3, and the upper end is connected to the feed port 5, and the figure 1 The spare motor 1 drives the degassing spinner 2 part. All the other are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com