Oxygen lance modified from accident cutting handle

A technology for oxygen-burning lances and accidents, which is applied to blast furnace parts, gas flame welding equipment, blast furnaces, etc. It can solve the problems of oxygen-burning lances that are prone to backfire and hurt people, so as to facilitate accident handling, avoid backfire accidents, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

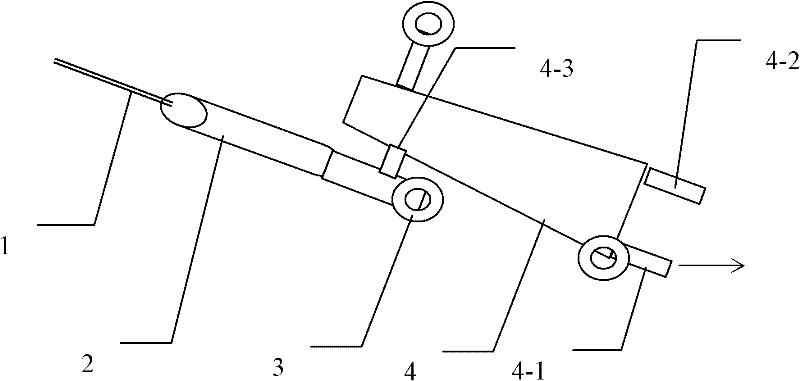

[0009] Specific embodiment one: below in conjunction with Fig. 1, present embodiment is described, and embodiment accident cutting handle changes burning oxygen gun, and it comprises burning oxygen pipe 1, seamless pipe 2, switch button 3, cutting handle 4, the rear end of cutting handle 4 It has a gas interface 4-1 and a sealed high-pressure oxygen interface 4-2, and the front end has a mixed gas interface 4-3;

[0010] The cutting handle 4 is arranged in parallel with the seamless pipe 2, and the inner wire is opened on the rear cylindrical wall of the seamless pipe 2, and is connected with the mixed gas interface 4-3 of the cutting handle 4;

[0011] The rear end of the seamless pipe 2 is provided with a switch button 3, and the front end of the seamless pipe 2 is connected with the oxygen burning pipe 1.

[0012] The oxygen burning tube 1 is made of copper.

[0013] The quarter seamless pipe of the seamless pipe 2, the length of the seamless pipe 2 is 15cm.

[0014] Duri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com