Pliant four-footed robot with flexible waist and elastic legs

A quadruped robot, flexible waist technology, applied in the direction of motor vehicles, transportation and packaging, etc., can solve the problems of high impact force of the legs, poor movement stability, uncoordinated movement, etc., achieve movement coordination, high stability, and reduce energy consumption. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention provides a compliant quadruped robot with a flexible waist and elastic legs. The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

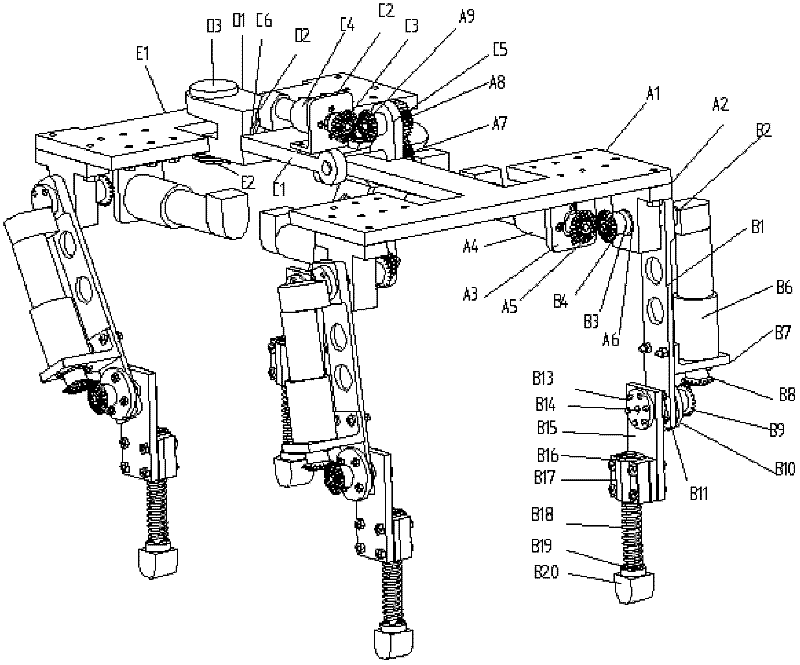

[0028] Such as figure 1 The shown robot is composed of front trunk A1, left front leg B1, spine C1, waist D1, rear trunk E1, right front leg, left rear leg, and right rear leg. The four legs have the same structure.

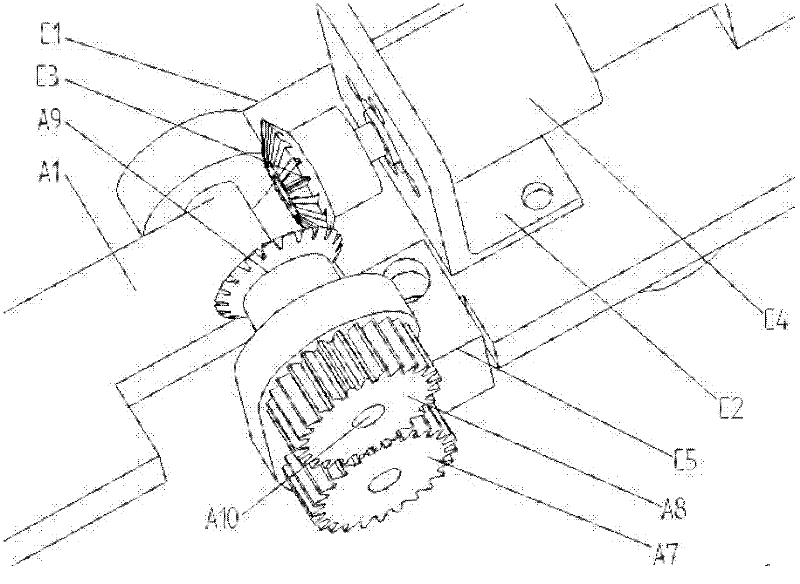

[0029] Such as figure 2 As shown, the front trunk A1 and the spine C1 are connected by a rotating joint, the end of the front trunk A1 is processed with a circular shaft, one end is inserted into the through hole at the end of the spine C1, and the other end is inserted into the through hole of the spine bearing seat C5, the spine The bearing seat C5 is connected to the spine C1 through bolts and nuts, so that the former trunk A1 and the spine C1 form a revolving pair. The spine motor C4 is fixed on the spine motor base C2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com