Tunnel type sterilizing drier

A dryer and tunnel technology, applied in packaging sterilization and other directions, can solve the problems of fast heating speed, increased motor load, slow hot air flow rate, etc., to achieve strong resistance to bending deformation, improve support ability, and ensure synchronization. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

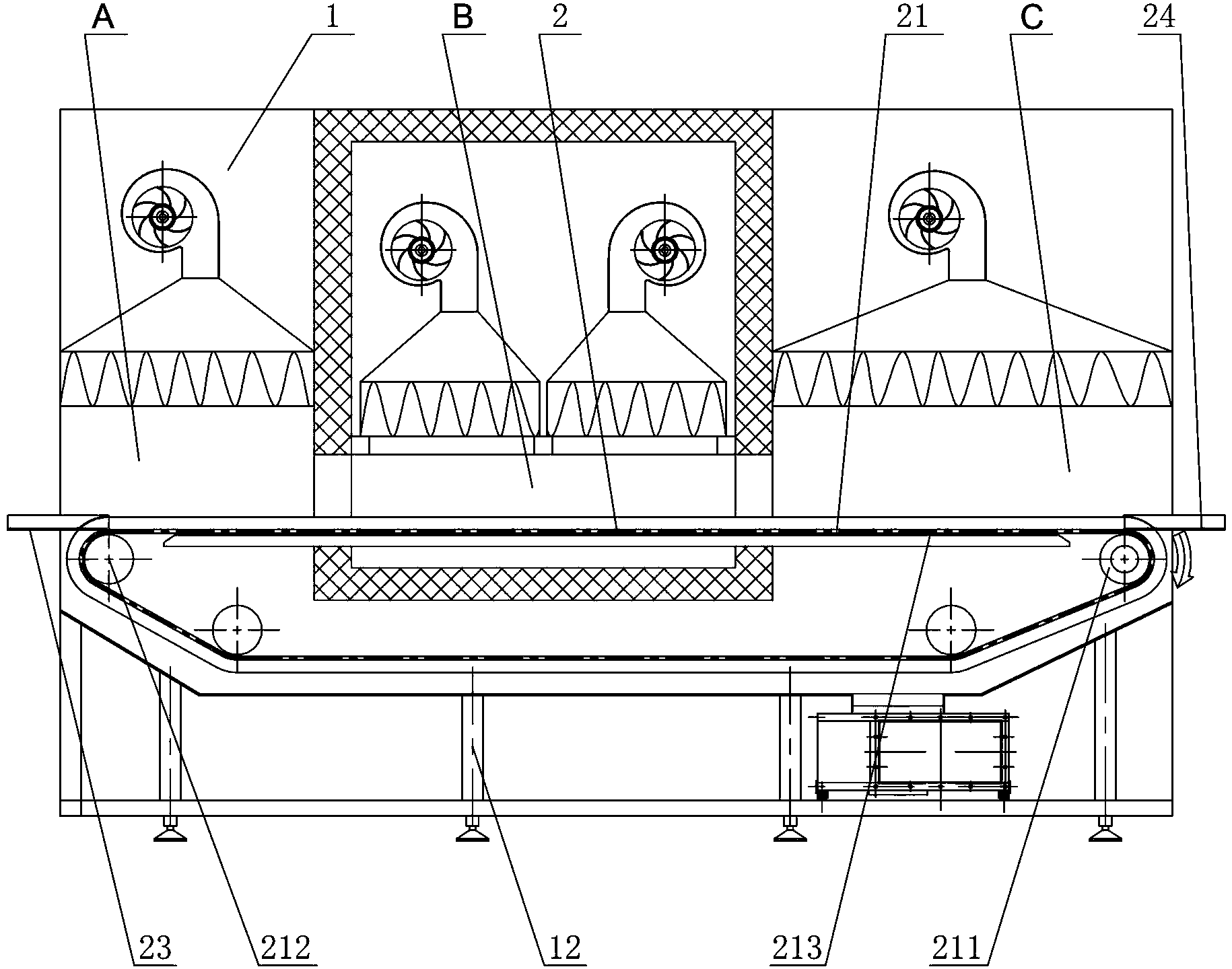

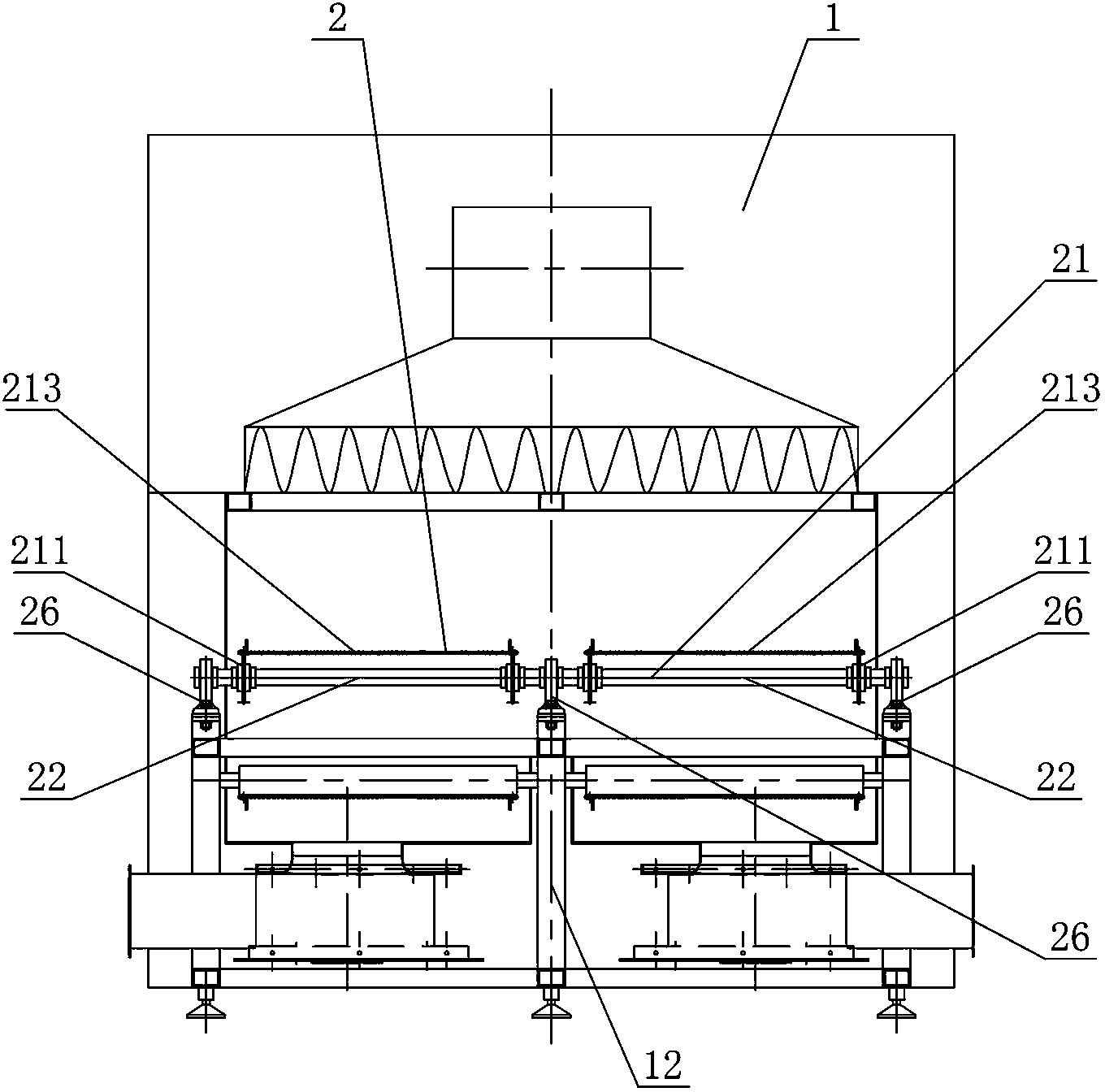

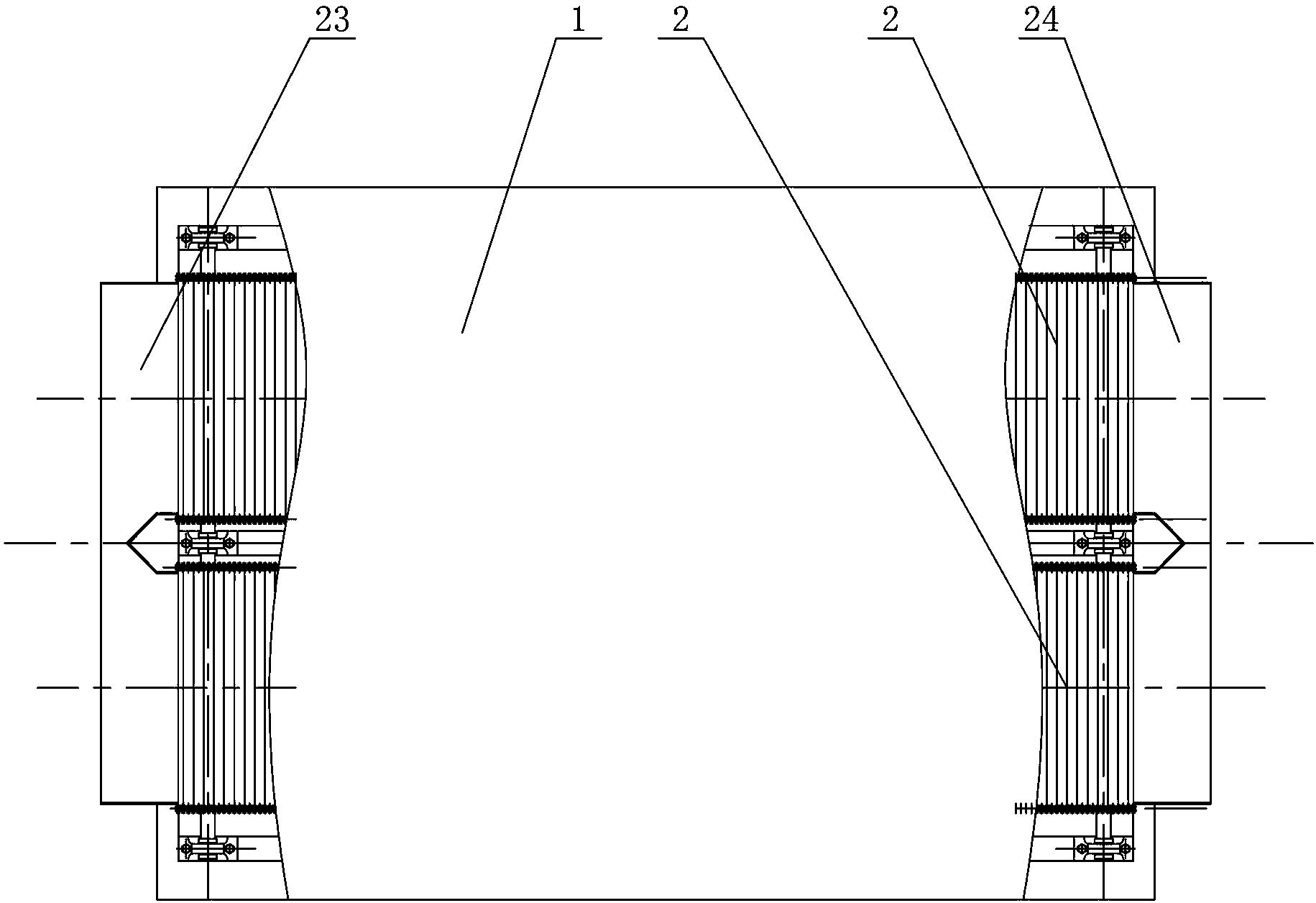

[0035] Such as Figure 1 to Figure 3 It shows the first embodiment of the tunnel type sterilization dryer of the present invention, the tunnel type sterilization dryer includes an oven 1 and a conveying mechanism 2 arranged in the oven 1, and the oven 1 is divided into preheating and Section A, high temperature section B, and cooling section C are prior art, and will not be repeated here. The conveying mechanism 2 of the present invention comprises two sets of conveying mesh belt assemblies 21 arranged side by side, and each group of conveying mesh belt assemblies 21 includes a driving sprocket 211, a driven sprocket 212 and a driving sprocket 211 and a driven sprocket 212 The conveying mesh belt 213 on the top, the tunnel type sterilization dryer of the present invention conveys the medicine bottle through two conveying mesh belts 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com