High-efficient strong filter press

A technology of filter press and press plate, which is applied in the field of filtration, can solve the problems of not being able to meet the requirements of output, small filter area, and low production efficiency, and achieve the effects of improving pressing efficiency, expanding pressing area, and shortening length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

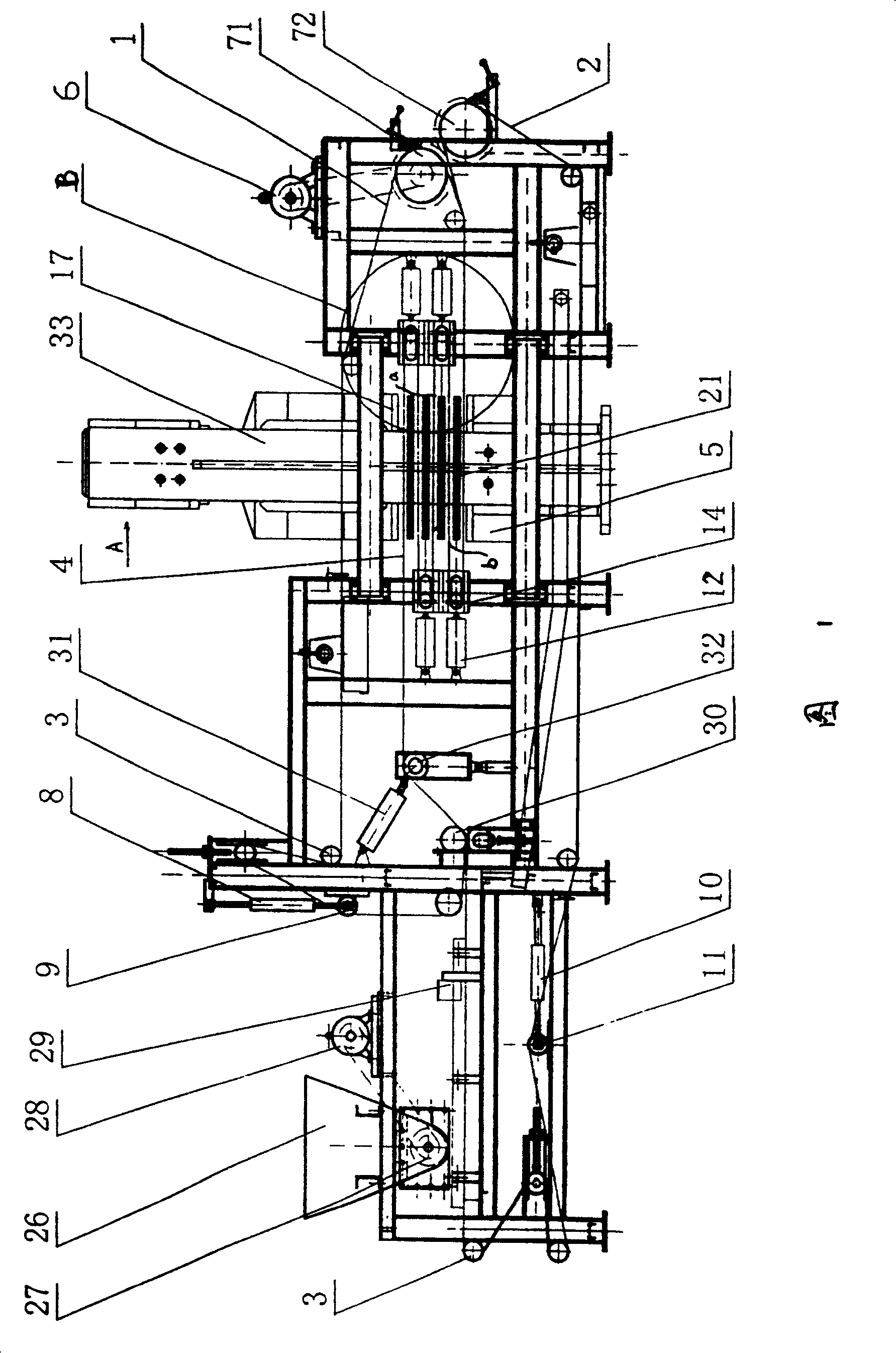

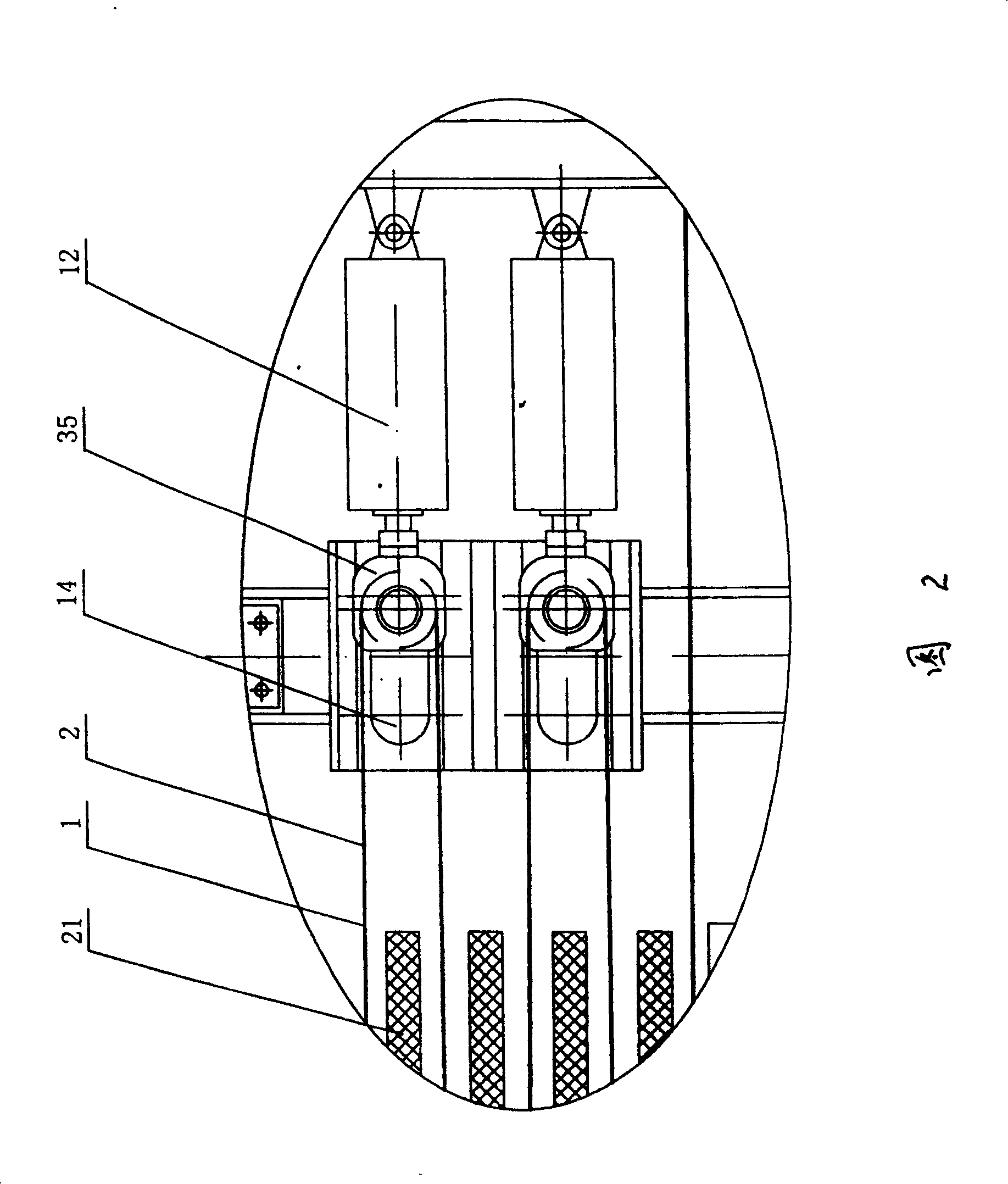

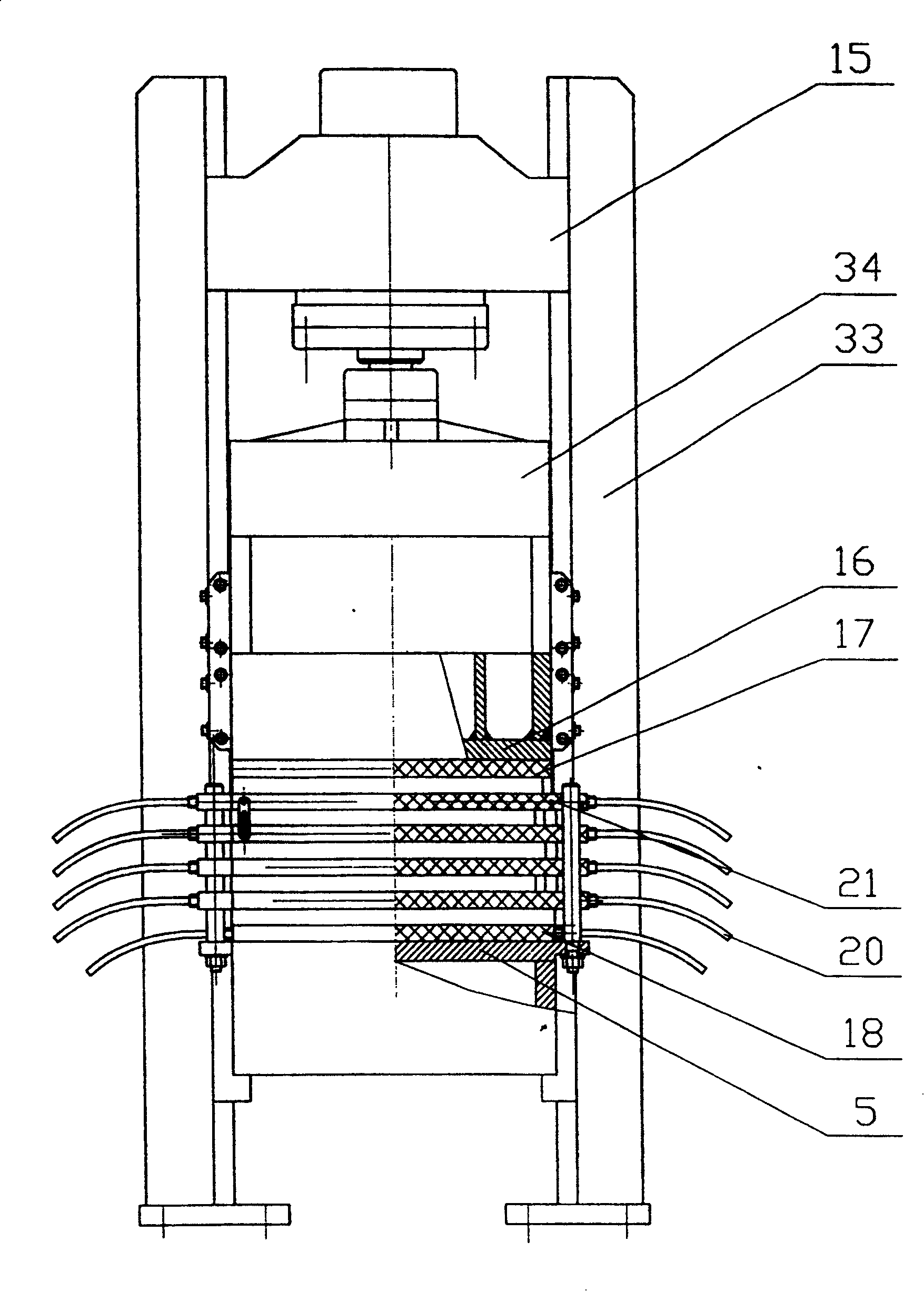

[0016] Refer to attached picture. The present invention includes matching upper and lower conveying material circulation mesh belts 1, 2 and a power mechanism for realizing the mesh belt circulation movement, a guide roller 3, and a mesh belt deviation correction device. In the S-shaped area 4, there is a press load-bearing platen 5, and a press plate 16 that reciprocates up and down corresponding to the press load-bearing platen, and it is also equipped with a loop mesh belt for relaxing and tensioning the S-shaped area. The mechanism, the movement of the circulating mesh belt, the relaxation and tensioning action of the circulating mesh belt in the S-shaped area, and the reciprocating movement of the pressing plate cooperate with each other.

[0017] As shown in Figure 1, after the lower circulating mesh belt receives the material, the upper circulating mesh belt and the lower circulating mesh belt are matched together to sandwich the material, and they also play the role of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com