Balance type cleaning machine for large-size cement silo

A cement silo and balance-type technology, which is applied to the field of large-scale cement silo balance-type silo cleaning machines, can solve the problems of low use efficiency of cement silo, easy to stick to the silo wall, and smaller volume of cement silo.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

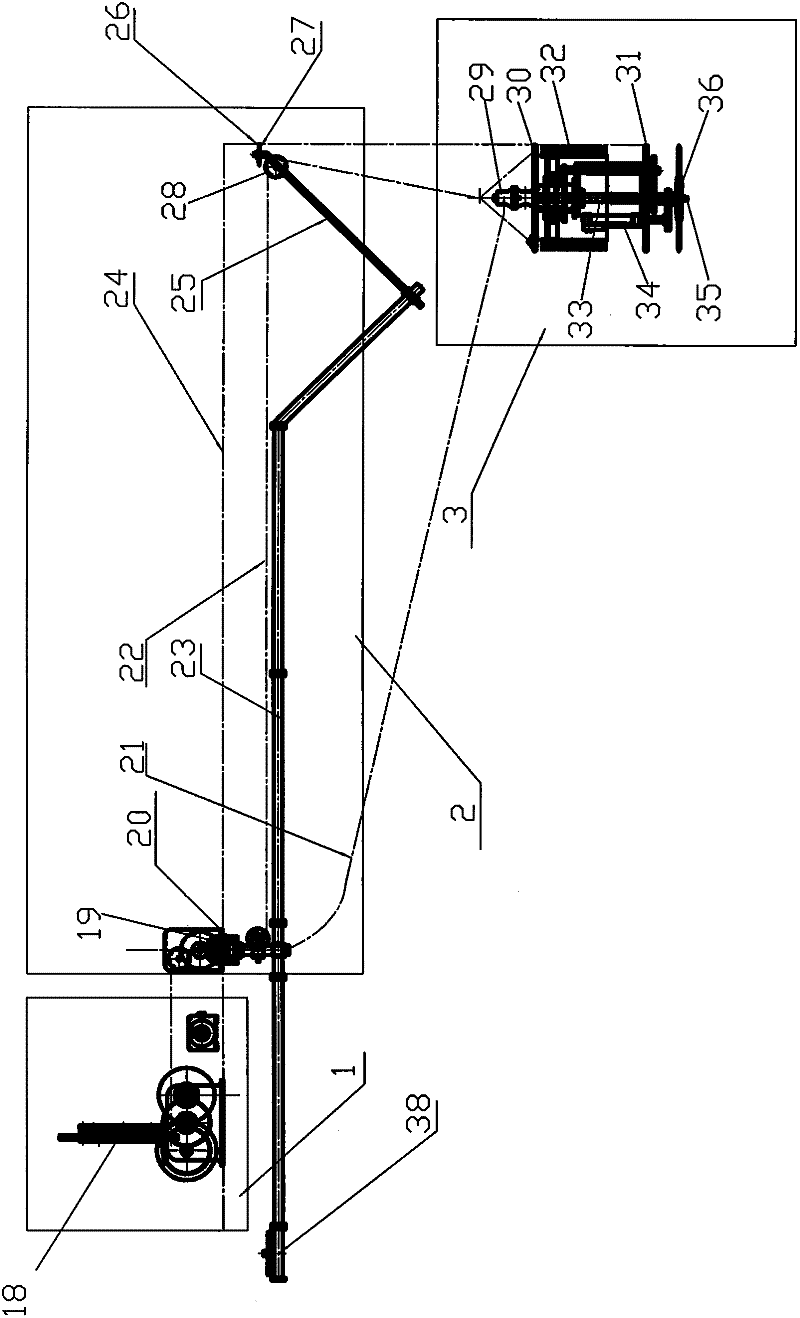

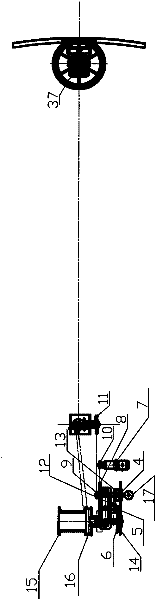

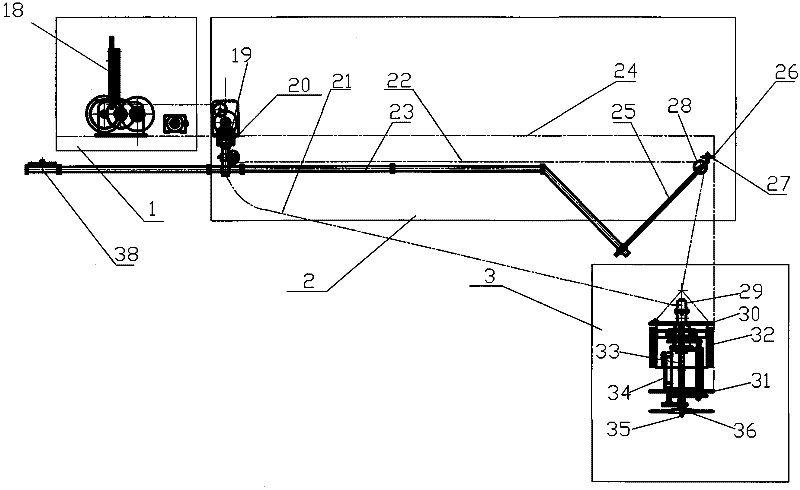

[0017] See figure 1 , figure 2 :

[0018] The balance type clearing machine for large cement warehouse of the present invention is composed of a main machine 1, an orbital rotating mechanism 2, and a clearing mechanism 3. The main machine 1 is composed of a motor 7, a reducer, a main shaft 4, an intermediate shaft 5, and a transmission shaft 6. , Wire rope reel 16, tracheal reel 15, clutch 12, 13, sprockets 8, 9, 10, 11, transmission chain, gear 14, height display mechanism 18, circumference display mechanism 17, the motor 7 through the reducer It is connected with the sprocket 9. The sprocket 9 is connected with the main shaft 4 through a transmission chain, a clutch, and a gear 14. The main shaft 4 is connected with an intermediate shaft 5 through a gear 14, and the intermediate shaft 5 is connected with a transmission shaft 6 through a clutch 13, 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com