Speed reducing shaft clutch for washing machine

A deceleration shaft and clutch technology, applied to clutches, non-mechanical drive clutches, washing machines with containers, etc., can solve the problems of inflexible control, not being too fast, complex structure, etc., and achieve accurate control, not easy to disengage, and small size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

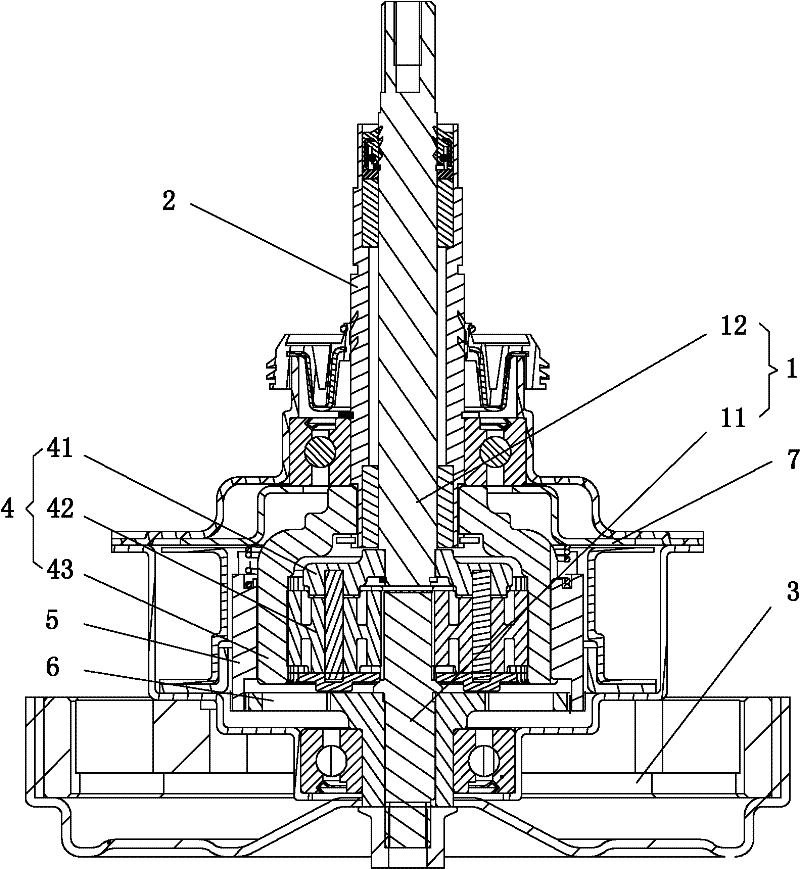

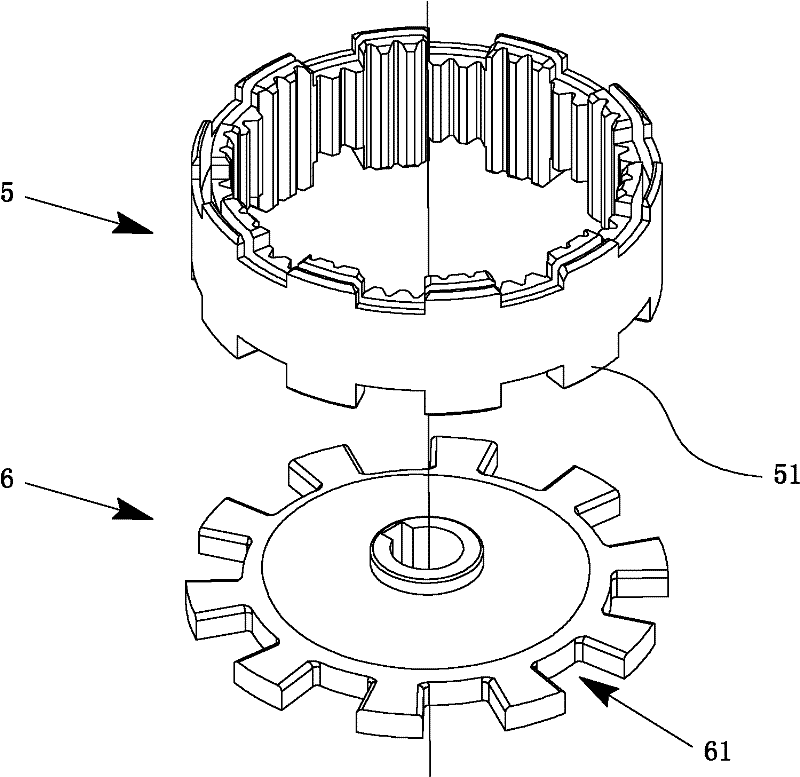

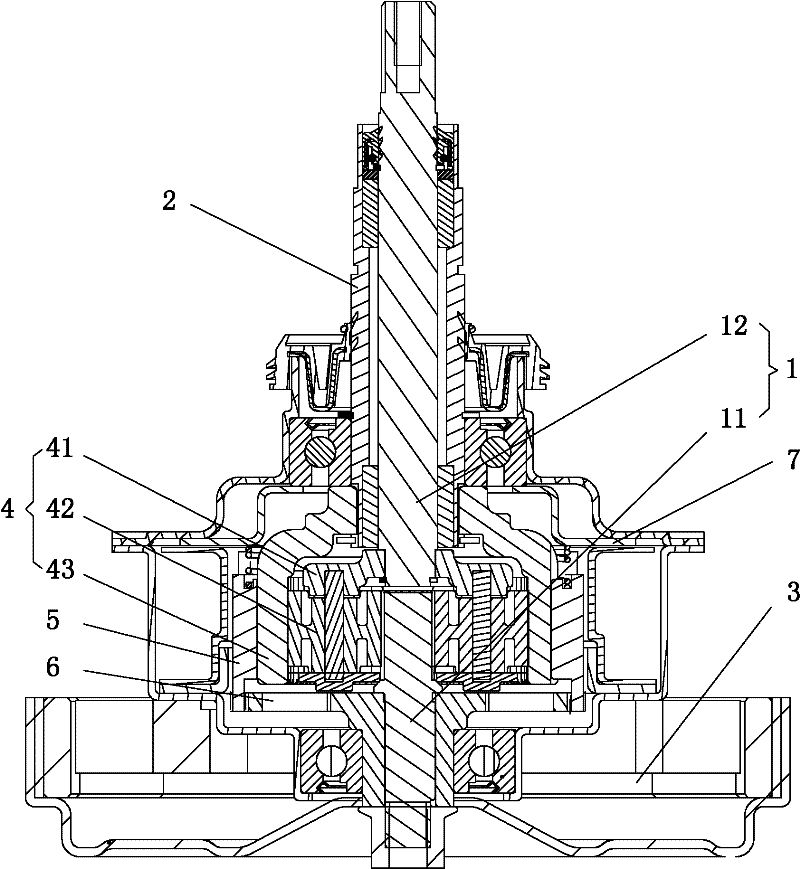

[0013] See figure 1 with figure 2 , the present invention has a drive shaft 1 and a drive shaft sleeve 2, the drive shaft 1 is rotatably arranged in the drive shaft sleeve 2, and the drive motor 3 is fixedly connected thereunder; it is characterized in that: the drive shaft 1 has a drive shaft arranged coaxially in the up and down direction Shaft 11 and transmission shaft 12, drive shaft 11 is connected with drive motor 3, planetary gear assembly 4 is arranged outside it, planetary gear assembly 4 has planetary gear cage 41, is arranged on planetary gear cage 41, and is in phase with drive shaft 11 The meshing planetary gear 42 and the planetary outer gear ring 43 arranged on the outer ring of the planetary gear 42 and meshed with the planetary gear 42, the planetary gear outer gear 43 is connected with the transmission shaft 12, and the outer planetary gear 43 is socketed Toothed clutch ring 5, spline fit between the toothed clutch ring 5 and the outer ring gear 43 of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com