Method for fabricating touch sensor panels

A touch sensor, panel technology, applied in printed circuit manufacturing, instruments, dual-use resists, etc., can solve the problems of expensive, high equipment and material costs, achieve effective manufacturing processes, reduce material costs and operating costs, and reduce steps. effect of numbers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

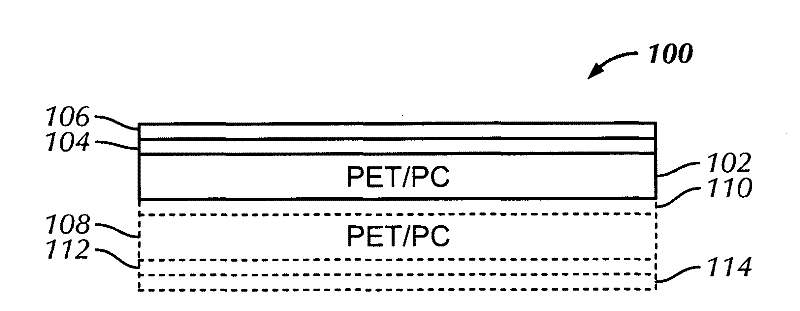

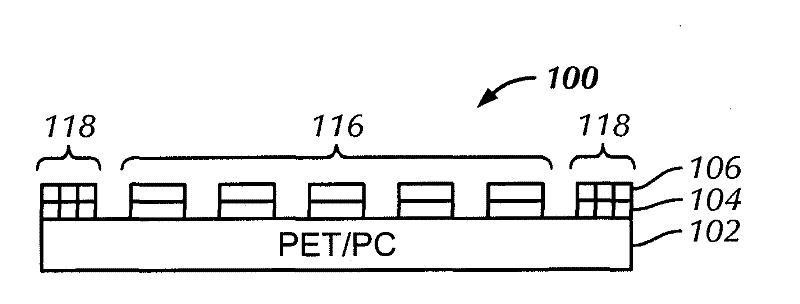

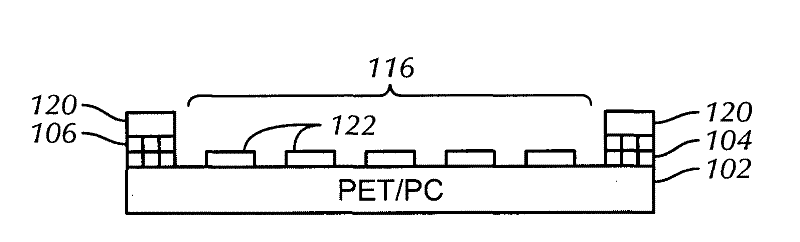

[0021] In the following description of the preferred embodiments, reference is made to the accompanying drawings which form a part hereof, and which illustrate specific embodiments that can be practiced. It is to be understood that other embodiments may be utilized and structural changes may be made without departing from the scope of the various embodiments of the present disclosure.

[0022] The invention relates to a method for manufacturing a touch sensor panel. In some touch sensor panel manufacturing processes, photoresist is applied to the panel during the photolithography / etch patterning process. The photoresist is stripped after the photolithography / etch patterning process is complete. A separate passivation layer is then applied in a subsequent passivation treatment. Thus, the entire manufacturing process is tedious and inefficient. Equipment and material costs are also relatively high due to the multiple printing and etching steps performed. Embodiments of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com