Fully-automatic microphone assembling equipment

A technology for assembling equipment and microphones, which is applied to sensors, electrical components, etc., can solve problems such as difficult automation, cumbersome assembly of parts, and difficulty in improving production efficiency, so as to shorten the cycle and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

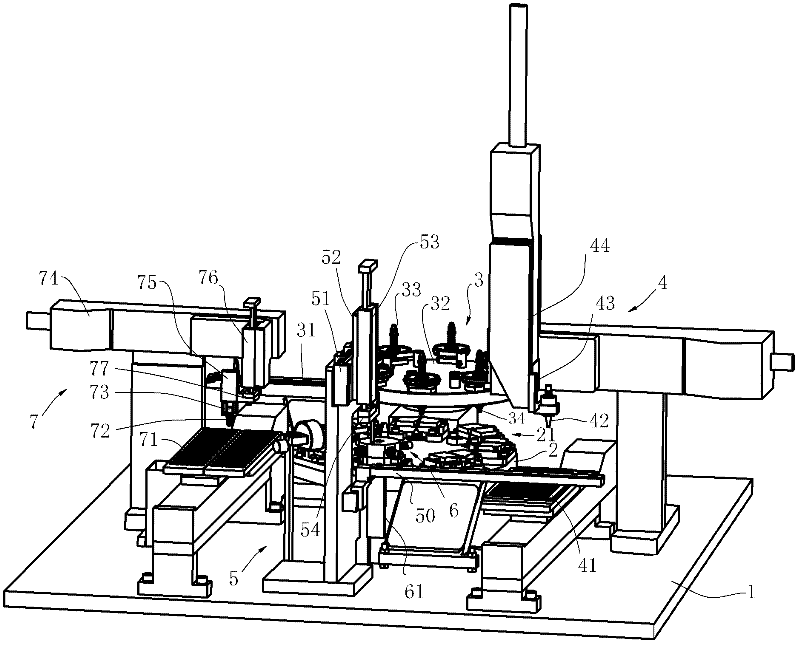

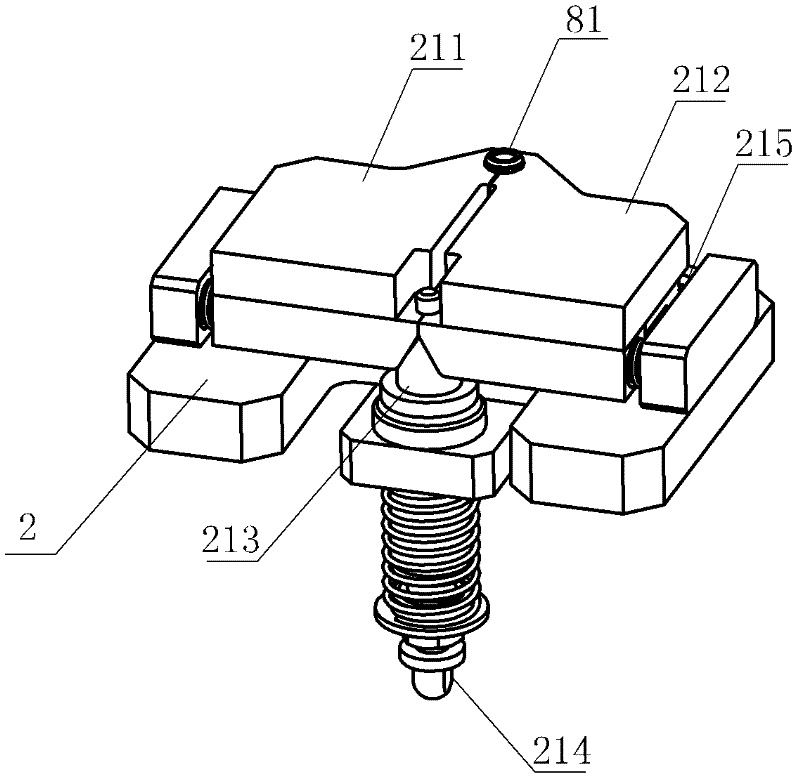

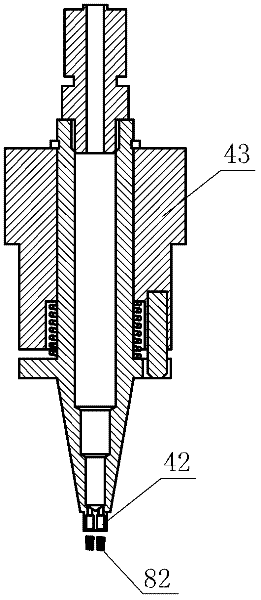

[0024] Such as figure 1 with figure 2 Commonly shown, a fully automatic microphone assembly equipment mainly includes a frame 1; on an assembly workbench 2 driven by a first power unit, the first power unit may be a servo motor or an indexing plate, and the assembly workbench 2 is Rotationally installed on the frame 1, the assembly workbench 2 is provided with a clamping and positioning device 21 for determining the position of each assembly element; it is used to extract the rubber sleeve 81 on the rubber sleeve delivery track 31 and place it on the The rubber sleeve conveying device 3 of the clamping positioning device 21, the rubber sleeve conveying device 3 can be installed on the frame 1, and can also be installed in other places where the position is fixed; it is used to extract the spring on the spring feeding tray 41 82 and placed on the spring conveying device 4 of the clamping and positioning device 21, the spring conveying device 4 is located at the downstream pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com