Full-automatic electric-induction garlic cusp distinguishing seeder

An electric induction, fully automatic technology, applied in the field of agricultural machinery, can solve the problems of unreachable plant spacing, consistent row spacing, inability to provide mechanized harvesting, delayed planting speed, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

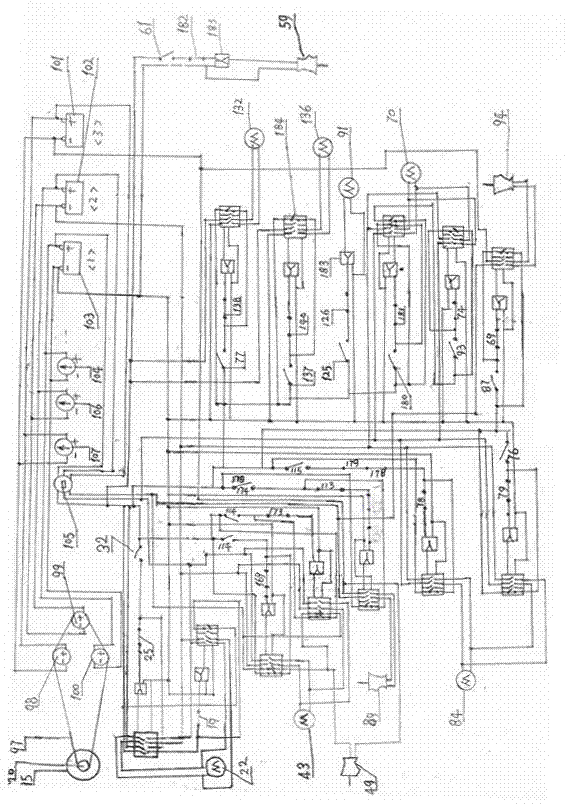

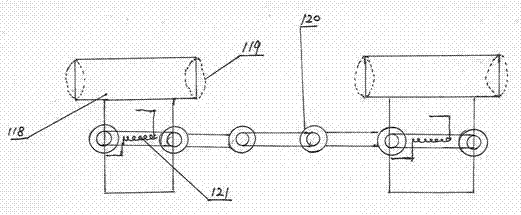

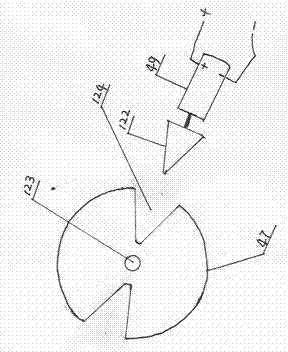

[0027] Accompanying drawing is a kind of specific embodiment of the present invention.

[0028] The automatic electric induction garlic cusp discrimination planter of the present invention comprises a frame that can be connected with a power device and a screening and picking device installed on the frame, a seed delivery device, a garlic cusp discrimination device, a hole punching device, a vertical The direct seeding device, the soil covering device, and the transmission device are installed on the frame; the screening and picking device includes a garlic hopper 1 installed on the upper left of the frame, the bottom of the garlic hopper has a leak hole for the whereabouts of garlic seeds, and a sowing device is installed below the garlic hopper. Sprocket pair, chain outer side has the tooth that is used to pull out the garlic seed from the leak hole, and the seeding sprocket wheel pair front bottom has the leaking sieve groove 7 that is used to miss the small garlic seed that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com