High-efficiency falling film evaporation reboiler

A falling-film evaporation and reboiler technology, applied in evaporator accessories, evaporation, boiling devices, etc., to achieve the effect of reducing equipment investment, accurate temperature control, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

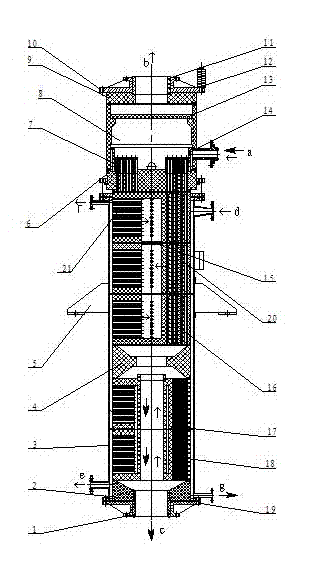

[0026] The present invention will be further described below using the accompanying drawings and examples.

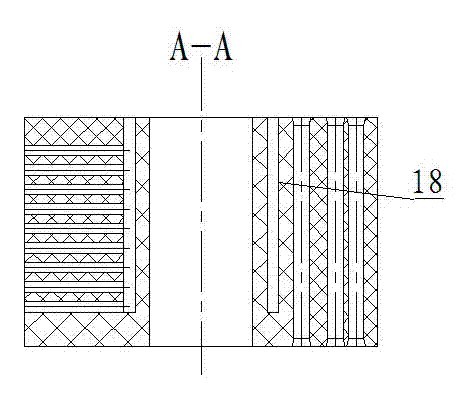

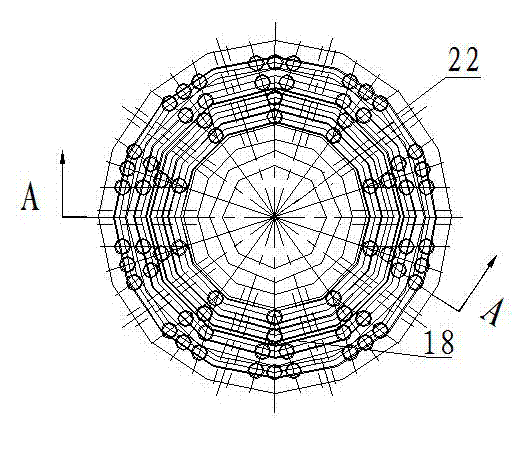

[0027] refer to figure 1 , The high-efficiency falling film evaporation reboiler of the present invention includes a cylinder body 3, and a support 5 is fixedly connected to the middle of the cylinder body 3, and the high-efficiency falling film evaporation reboiler is installed on a position of a set height through the support 5. A steam inlet d and a vent opening f are arranged on the upper part of the cylinder body 3, and a steam outlet e and a clean outlet g are arranged on the lower part of the cylinder body 3. The vent port f is used to vent the internal gas before the test run, and the drain port g is used to drain the internal liquid after parking. The lower end of the cylinder body 3 is fixedly connected with the lower cover plate 19, and the lower cover plate 19 is provided with a lower head 2, and a lower connection pipe 1 is fixedly connected in the lower h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com