Reaction kettle for producing static material not easy to flow and use method thereof

A reaction kettle and material technology, applied in the field of biopharmaceuticals, can solve the problems of unstable performance, uneven stirring and mixing, and insufficient reaction, and achieve the effects of improving product quality, improving production efficiency, and ensuring discharge efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention will be further described.

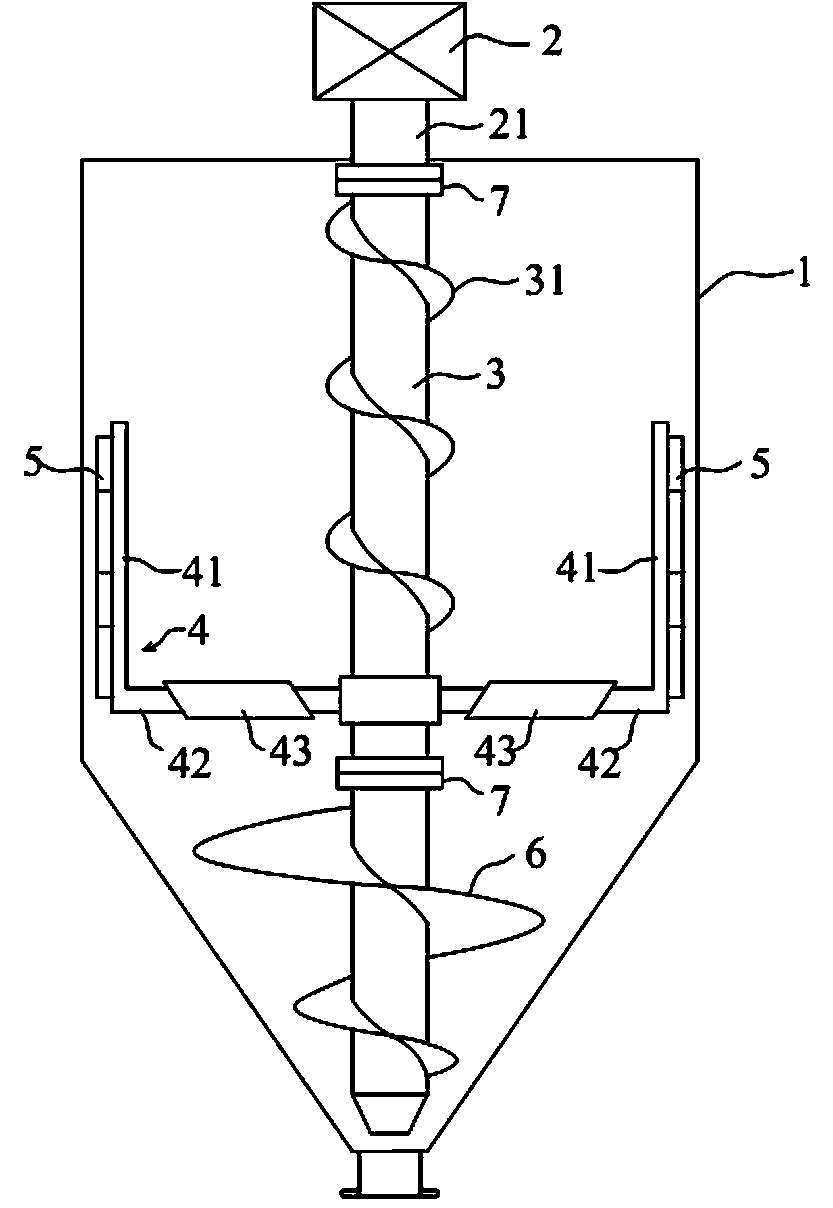

[0018] Such as figure 1 , the reactor of the present invention that is used to produce the material that is static and difficult to flow, comprises the reactor body 1 of reactor, and drive motor 2 is installed on the top of reactor body 1, and the rotating shaft of driving motor 2 is connected with rotating shaft 3, rotates An anchor agitator 4 is installed on the shaft, and the rotating shaft is a screw agitator provided with a helical blade 31. The lower end of the screw agitator is connected with a conical screw 6, and the conical blade of the conical screw 6 is connected to the bottom of the kettle body. The inverted conical shape is adapted, the gap between the conical screw 6 and the inner wall of the kettle body 1 is 10-20mm, and the direction of the axial force generated by the rotation of the conical screw 6 is the same as the direction of the axial force generate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com