Method for calibrating radial eccentricity parameters in milling process of flat head end mill

A flat end mill and parameter calibration technology, applied in metal processing mechanical parts, measuring/indicating equipment, metal processing equipment, etc., can solve problems such as unfavorable engineering applications and expensive milling force testing equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

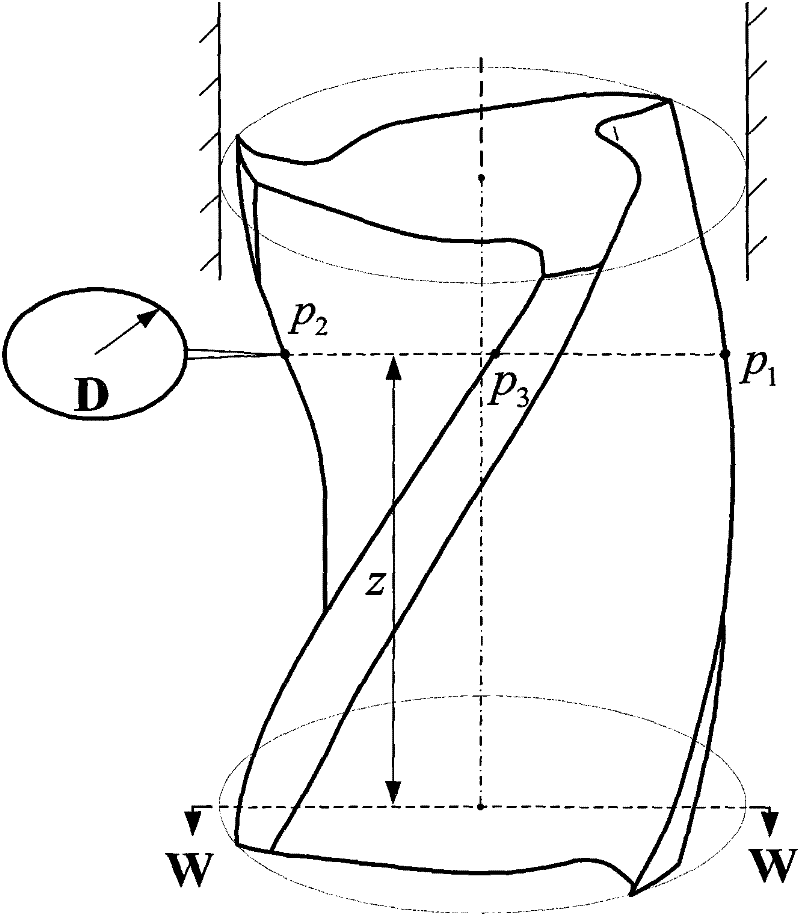

[0051] (1) Select the parameters of the end mill: the tool radius R is 8mm, the helix angle β is 30 degrees, and the number of tool teeth is N f is 3, assuming that the milling cutter is mounted on a three-axis vertical milling machine.

[0052] (2) Select N=4 tool axial positions, and mark the coordinates of each axial position as z 1 = 0, z 2 =6.5mm,z 3 = 18.3 mm, z4 = 28.2 mm.

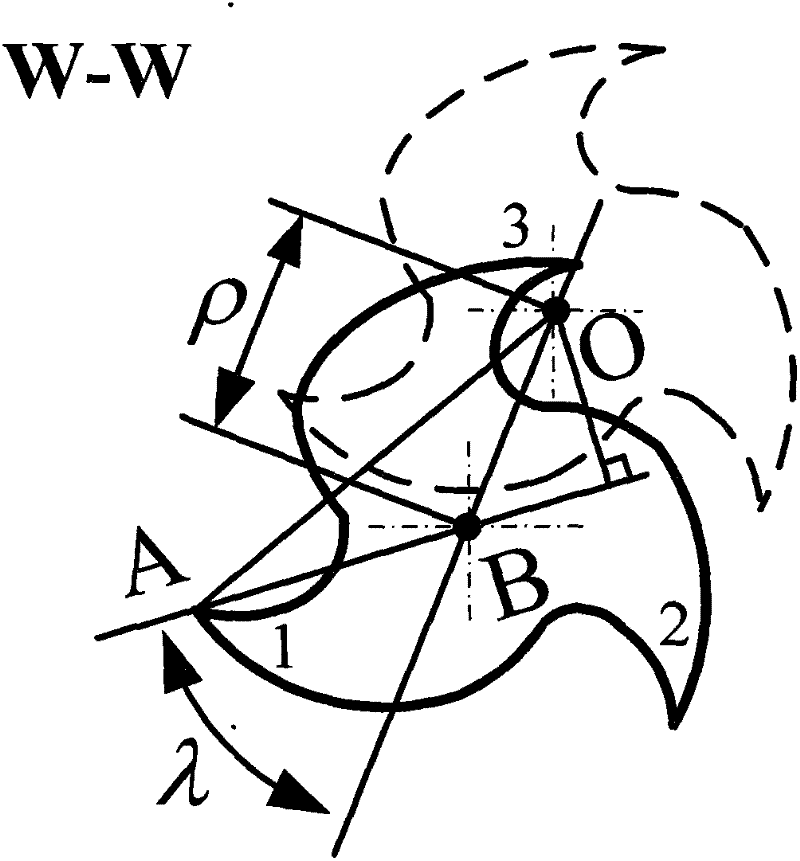

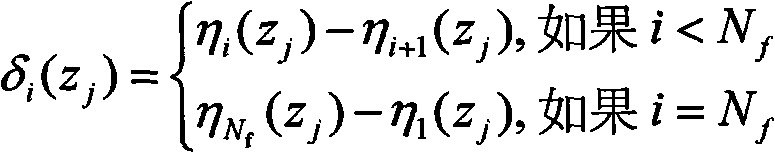

[0053] (3) At each axial position z j , to establish the deviation between tooth i and the axis of rotation of the machine tool spindle. Without loss of generality, according to the method in Document 3, for each axial position z j , first construct a set of deviations between the cutter teeth corresponding to the eccentric parameters ρ=8.31μm and λ=31.918° and the center of rotation of the machine tool spindle, and record the result as η i (z j ), as shown in the table below, j=1, 2,..., N, i=1, 2,..., N f . In order to be close to the actual test situation, when constructing η i (z j ),...

Embodiment 2

[0077] (1) Select the parameters of the end mill: the tool radius R is 8mm, the helix angle β is 30 degrees, and the number of tool teeth is N f is 3, assuming that the milling cutter is mounted on a three-axis vertical milling machine.

[0078] (2) Select N=1 tool axial position, and mark the coordinate of this axial position as z 1 =0.

[0079] (3) At the axial position z 1 , to establish the deviation between the cutter tooth i and the center of rotation of the machine tool spindle. Without loss of generality, according to the method in Document 3, first construct a set of deviations between the cutter teeth corresponding to the eccentric parameters ρ=8.31μm and λ=31.918° and the center of rotation of the machine tool spindle, and record the result as η i (z 1 ), as shown in the table below, i=1, 2, .., N f . In order to be close to the actual test situation, when constructing η i (z 1 ), a random error not exceeding 2.5 μm is added.

[0080]

[0081] (4) Accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com