Spiral flow type oil skimmer

A technology of oil skimmer and swirling flow, which is applied in the direction of grease/oily substance/suspton removal device, liquid separation, separation method, etc., can solve the problems of potential safety hazards and damage to health, and achieve simple and exquisite structure, improve Efficiency, the effect of eliminating personnel poisoning and fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

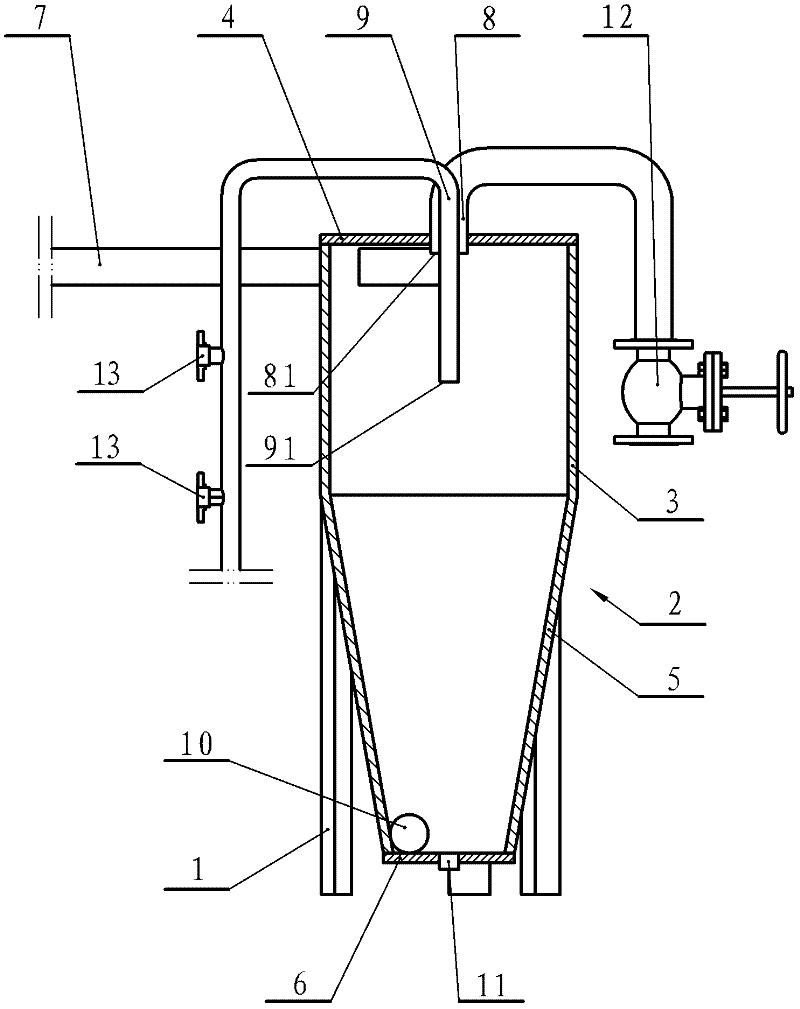

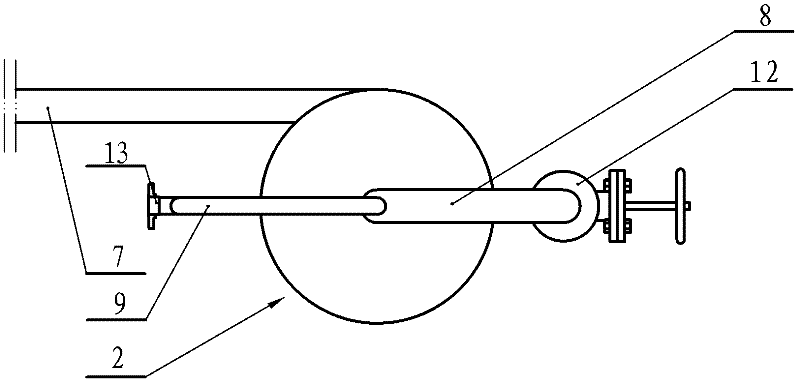

[0023] The swirl oil skimmer of the present invention has a schematic cross-sectional structure such as figure 1 As shown, it includes a bracket 1 and an oil skimmer body 2, the oil skimmer body 2 is a hollow cylindrical structure, the upper part of the cylindrical structure is a vertical straight cylindrical structure 3, and the upper end of the straight cylindrical structure 3 is closed with an upper closed end cover 4 , the lower end of the straight cylinder structure 3 is provided with a vertical cone structure 5, the diameter of the upper end of the cone structure 5 is greater than the diameter of the lower end of the cone structure 5, the diameter of the upper end of the cone structure 5 is the same as the diameter of the straight structure 3 and is connected through a closed connection, The lower end of the cone structure 5 is closed with a lower closed end cover 6, the outer circumferential surface of the upper end of the straight tube structure 3 is provided with a liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com