Evaporative cooling water chiller unit based on split heat pipe

A split-type heat pipe and evaporative cooling technology, which is applied in the direction of household heating, heating mode, household heating, etc., can solve the problems of inability to meet the requirements of the sensible heat end, large irreversible losses, low heat and moisture exchange efficiency, etc. Operating expenses, increased reliability, improved utilization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

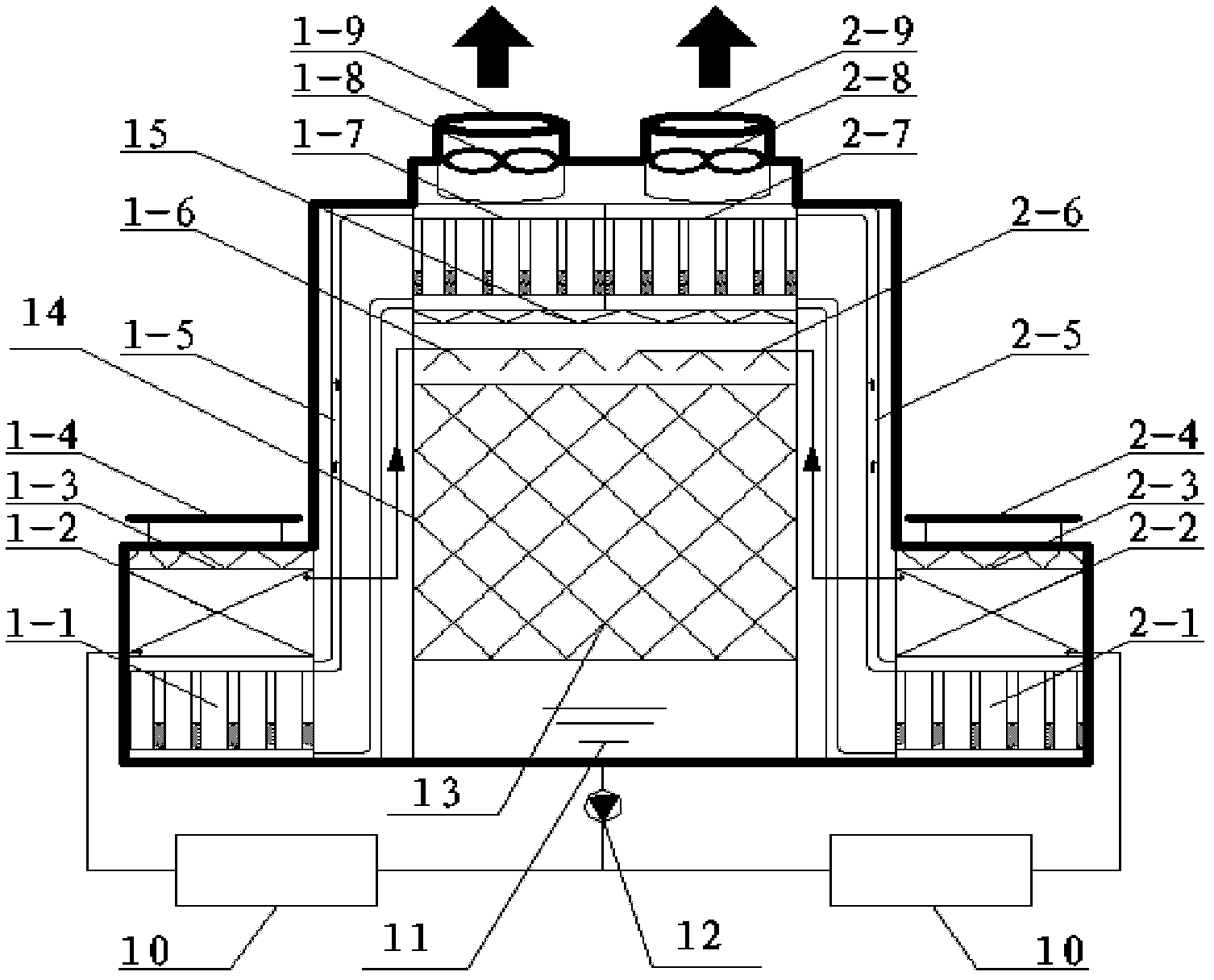

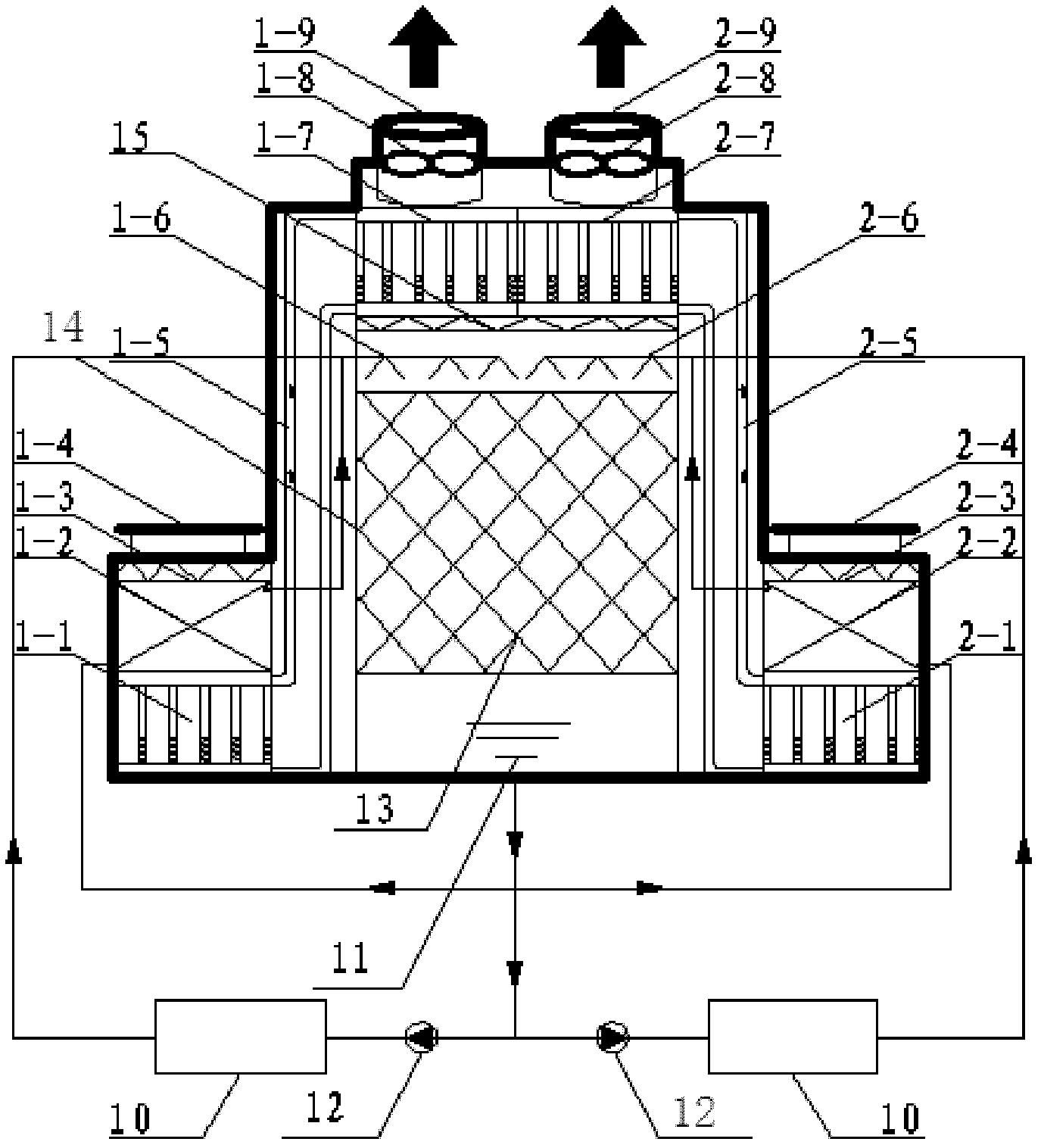

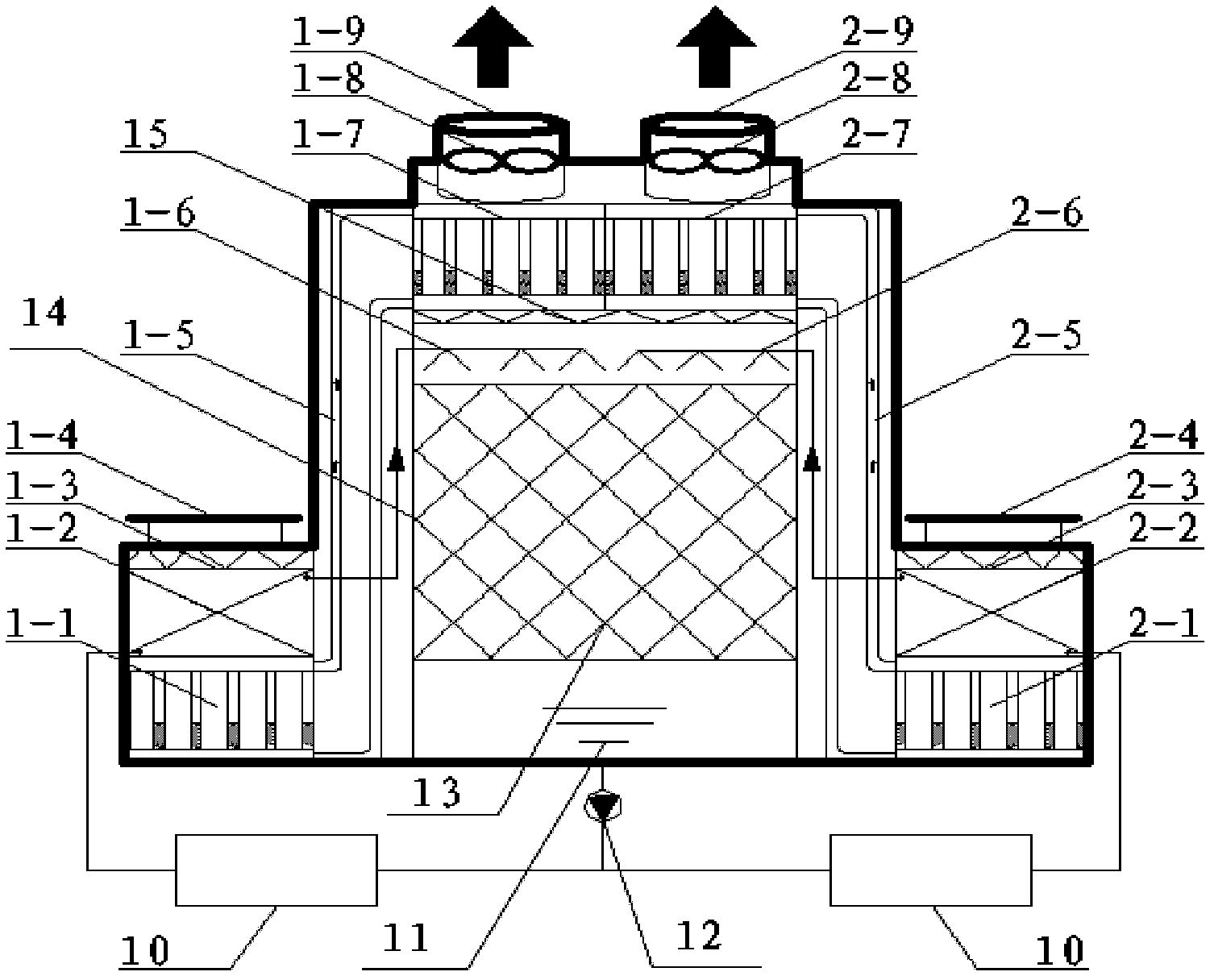

[0021] The structure of the evaporative cooling chiller based on the split heat pipe of the present invention is composed of an air cooler, a split heat pipe and a direct evaporative cooler, and the structures on the left and right sides are completely symmetrical with the direct evaporative cooler as the center.

[0022] figure 1 Shown is an embodiment provided by the present invention. The direct evaporative cooler 14 in the casing of the unit is composed of a filler 13, a water tank 11 at the lower part of the filler 13, a water distributor and a water baffle 15 at the upper part of the filler 13, and the water distributor is divided into There are two left and right water distributors a1-6 and water distributor b2-6, and two exhaust fans are arranged side by side on the upper part of the water retaining plate 15: exhaust fan a1-8, exhaust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com