High temperature chiller with inclined section tubular indirect evaporative cooler

A technology of evaporative coolers and chillers, which is applied in the field of air conditioning and refrigeration, can solve the problems that air cannot be used more reasonably, and achieve the effects of improving efficiency, increasing contact area, and improving the degree of pre-cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

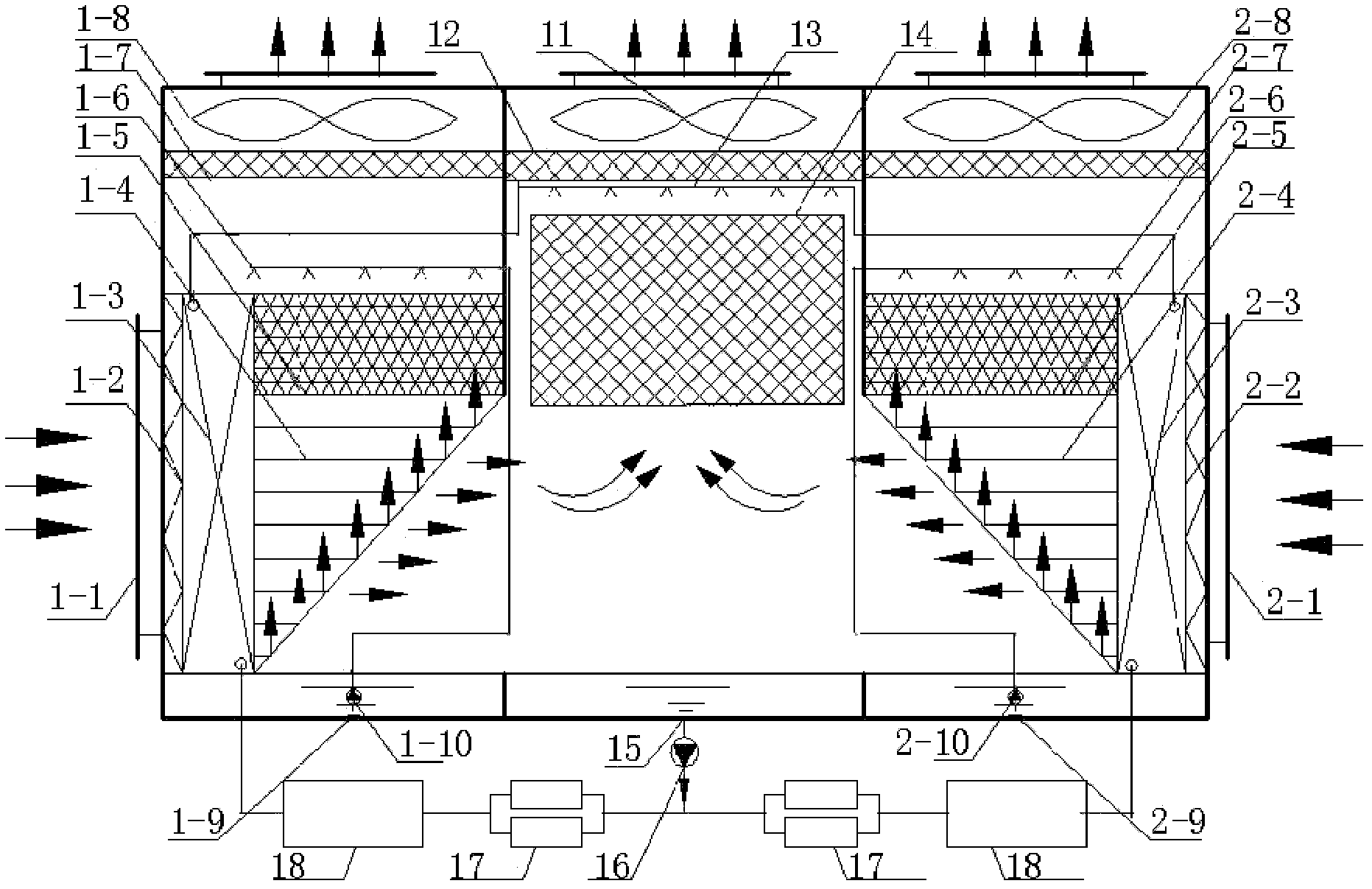

[0026] The present invention adopts the high-temperature water chiller of oblique cross-section tube type indirect evaporative cooler, and its structure is as follows: figure 1 As shown, it includes an organic unit casing, and two groups of air cooling devices with the same structure are arranged symmetrically on the left and right sides of the group casing, filler II14 is arranged between the two groups of air cooling devices, and a water baffle is arranged above the first group of air cooling devices a1-7, the fan a1-8 is installed above the water baffle a1-7, the water baffle b2-7 is installed above the second group of air cooling devices, the fan b2-8 is installed above the water baffle b2-7, and the packing II14 The upper part is provided with a water baffle c12, and the fan c11 is arranged above the water baffle c12, and the side wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com