Gravity type heat pipe and direct evaporation cooler compound evaporating and cooling water chilling unit

A technology of evaporative coolers and gravity heat pipes, which is applied in the direction of indirect heat exchangers, space heating and ventilation, space heating and ventilation details, etc., can solve the problems of unreasonable utilization, achieve structural optimization, and improve pre-cooling Degree, compact and ingenious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

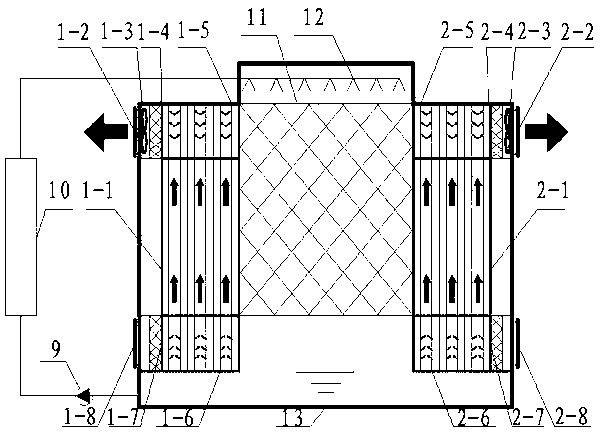

[0017] The structure of the evaporative cooling water chiller of the present invention is composed of a filter, a gravity heat pipe and a direct evaporative cooler, and the structures on the left and right sides are completely symmetrical with the direct evaporative cooler as the center. figure 1 This is an embodiment where the filter, gravity heat pipe, and direct evaporative cooler are placed in the same enclosure, showing their relative positions.

[0018] like figure 1 As shown, the evaporative cooling water chiller of the present invention includes a direct evaporative cooler, which is composed of filler 11, a water tank 13 at the bottom of the filler 11, and a spray water device 12 at the top of the filler 11. The water tank 13 is connected to the The sensible heat terminal 10 outside the unit is connected, and the sensible heat termin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com