Method for measuring spot size of multi-element infrared ray shaft temperature detector

A measurement method and detector technology, applied in the direction of testing optical performance, etc., can solve the problems of poor operability, response signal attenuation, and inability to accurately judge the size of the spot, etc., to achieve rich information, improve measurement accuracy, and simple and fast measurement methods Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0027] A method for measuring the spot size of a multi-element infrared axial temperature detector proposed by the present invention specifically includes the following steps:

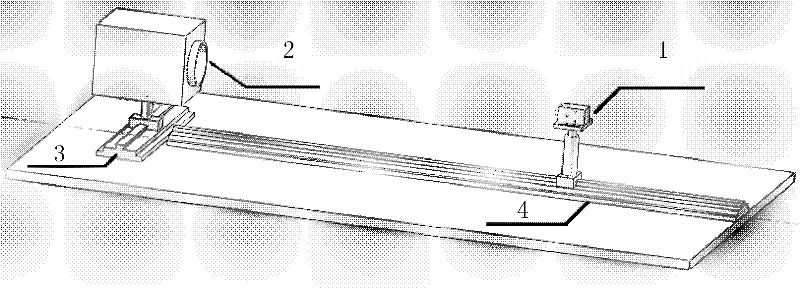

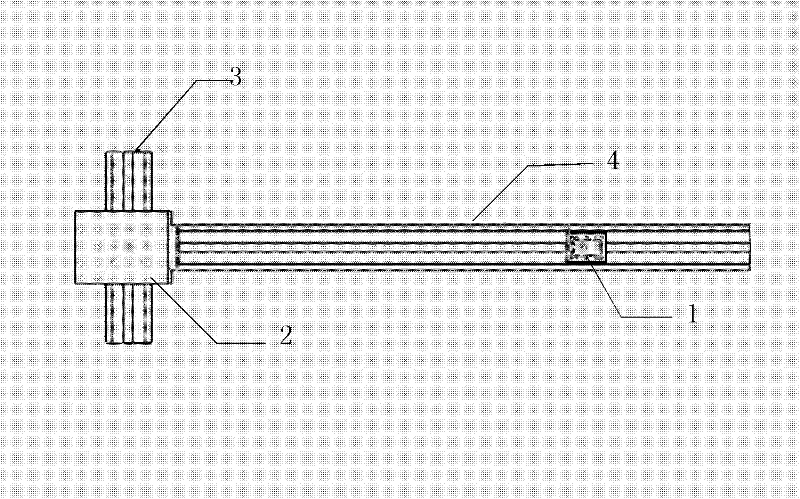

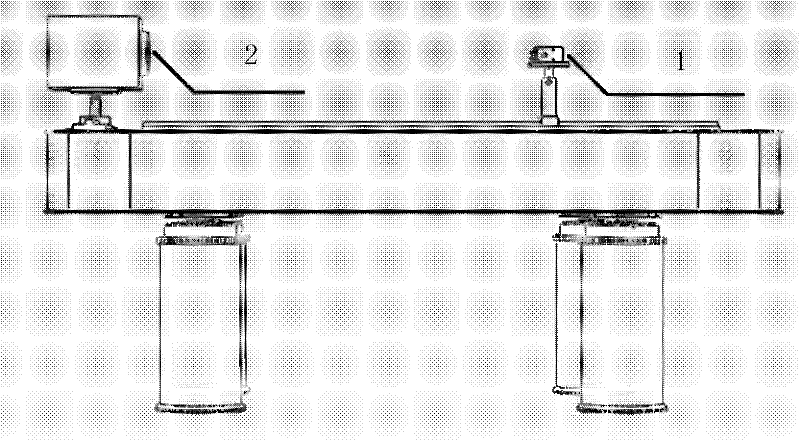

[0028] Step 1: Place the detector 1 on the B guide rail 4 of the T-shaped guide rail of the test platform, and adjust the direction of the detector 1 so that the normal line of the sensitive surface of the detector 1 is parallel to the B guide rail 4, and place the blackbody 2 on the A guide rail 3 The 0 scale position of the upper scale, the 0 scale is located on the side of the A guide rail 3, and the A guide rail 3 and the B guide rail 4 are kept vertical, such as Figure 1-A , 1-B and 1-C.

[0029] Step 2: Adjust the position of the detector 1 on the B guide rail 4, and set the detector 1 at a vertical distance of 50-100 cm from the A guide rail 3. At the same time, adjust the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com