Identification method of two-dimensional barcode image on high-reflect light cylindrical metal

A two-dimensional barcode and image recognition technology, applied in the field of automatic identification, can solve problems such as inability to read two-dimensional DataMatrix barcodes, software not implemented, and barcode shape distortion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0145] Example 1: Single image recognition

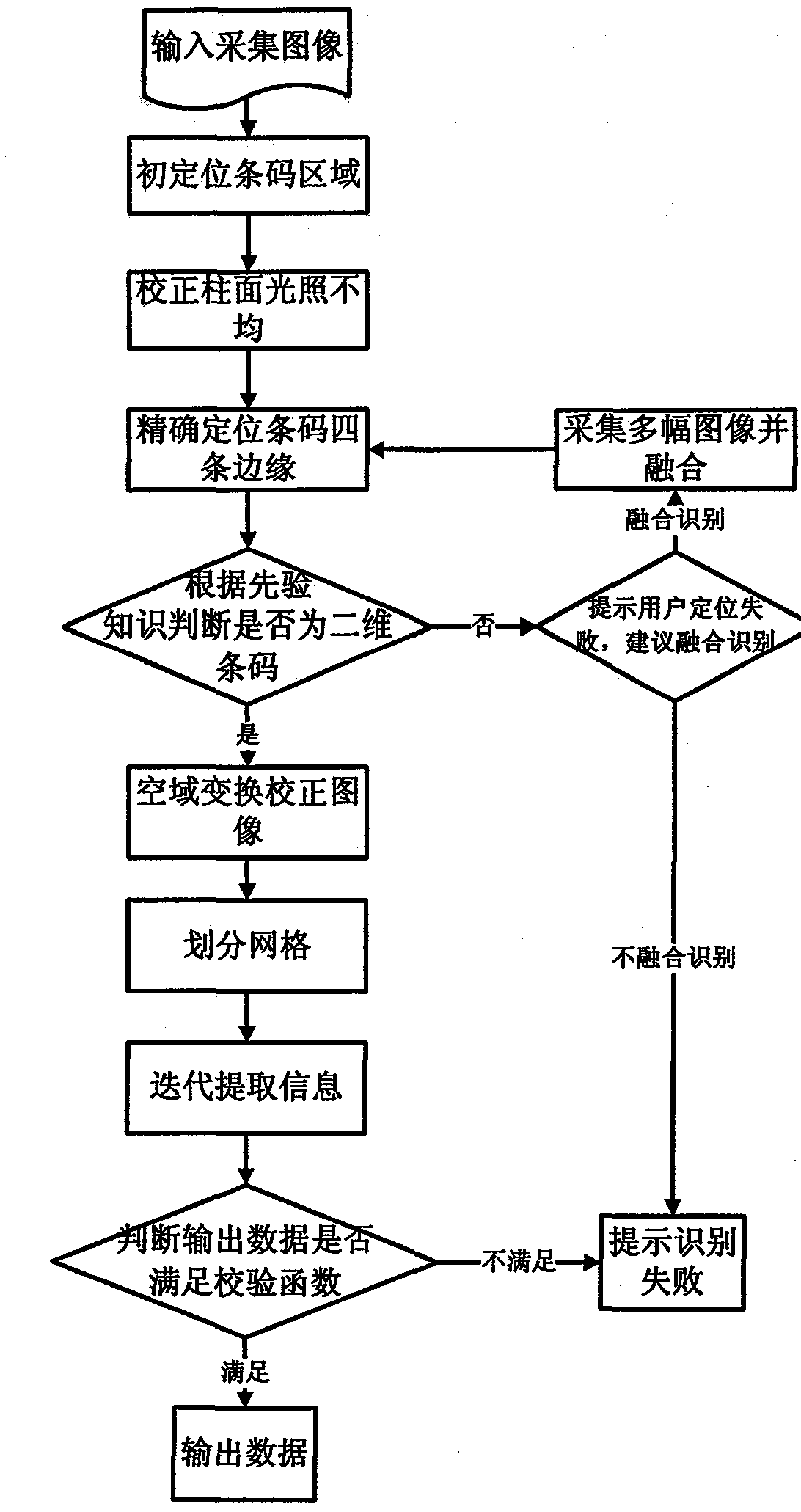

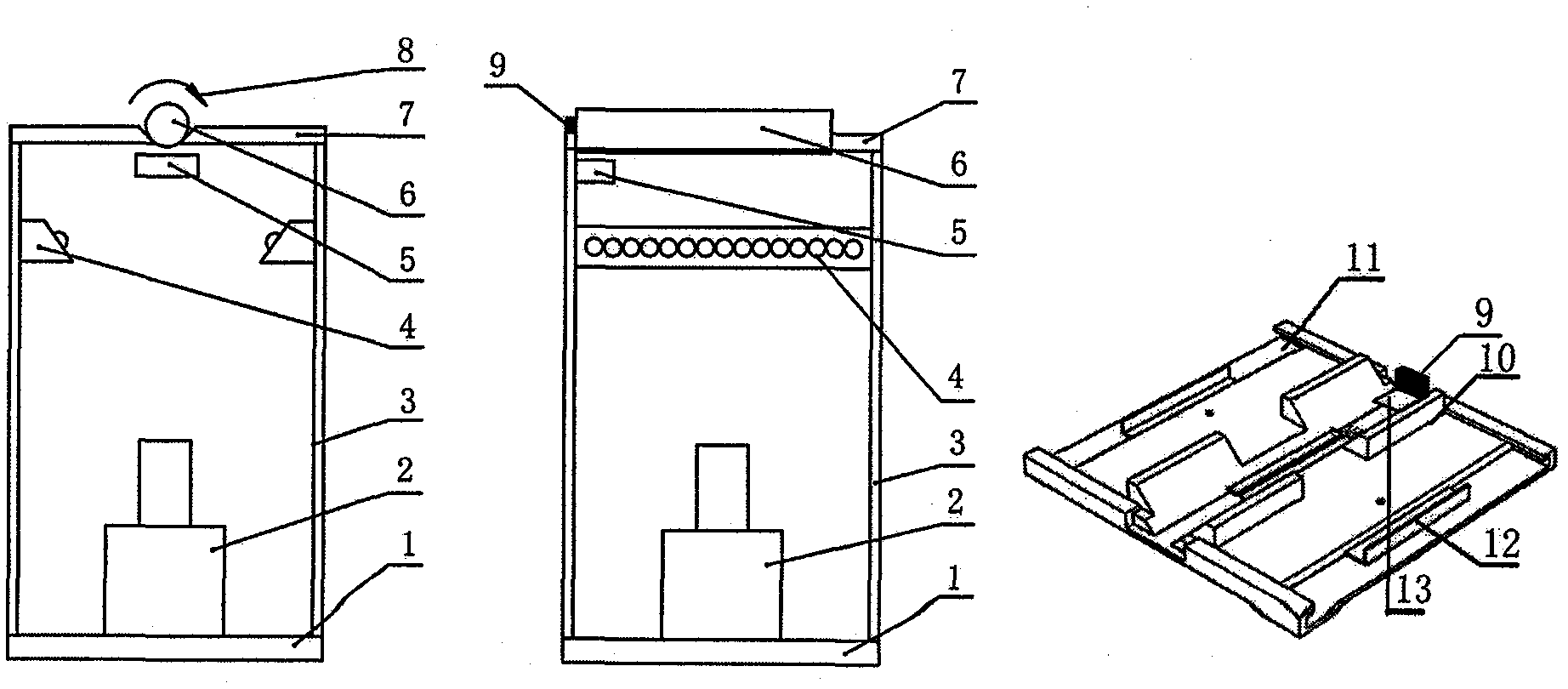

[0146] Such as Figure 8 As shown, this example selects a cylindrical metal with a diameter of Φ12, and uses MV1300 to capture the two-dimensional barcode image on it under the reading tool. Schematic diagram of reading tooling such as figure 2 shown. In this example, the shutter speed is 7ms, the gain adjustment is 58, the image size is 640*512pix, the acquisition speed is high speed, and the reflective tape does not cover the two-dimensional barcode information. In order to achieve the above object, the overall process of the technical solution of the present invention is as follows: figure 1 shown.

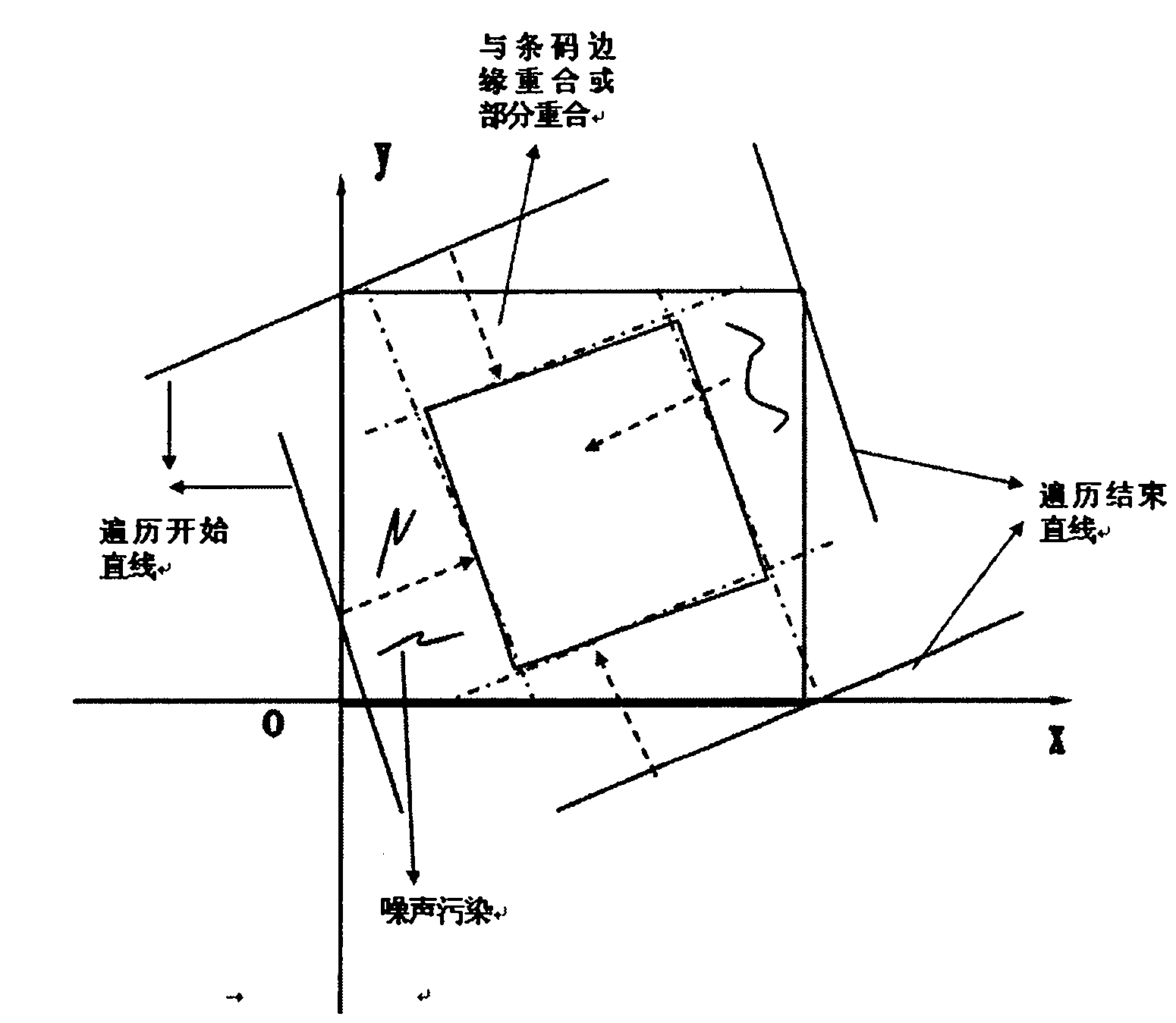

[0147] 1. Under the reading tool, the two-dimensional barcode image captured is as follows: Figure 8 shown. Firstly, according to the fact that there are two white sides in the two-dimensional barcode area as positioning sides, determine the position of the two-dimensional barcode in the horizontal direction: xlef=182, xrigt=...

example 2

[0158] Example 2: fusion recognition

[0159] Such as Figure 10 As shown, this example selects a cylindrical metal with a diameter of Φ6, and takes a two-dimensional barcode image on it. Since the radius of the cylinder is small and the curvature is too large, no matter how you adjust the camera parameters, it is impossible to eliminate part of the two-dimensional barcode information covered by the reflective tape, so fusion recognition should be adopted. In this example, the shutter speed is 7us, the gain adjustment is 58, the image size is 640*512pix, and the acquisition speed is high speed.

[0160] 1. Adjust the black metal baffle to make the gap smaller appropriately, and at the same time observe the image displayed in the video display box on the right until the highly reflective area is removed. Then this example selects 2 seconds to read 4 images, the read images are as follows Figure 11 Shown in (a).

[0161] 2. As shown in the algorithm in 5.5, the four images ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com