OLED (Optical Light Emitting Device) illuminating device and manufacture method thereof

A technology for lighting devices and transparent anodes, applied in the field of lighting, can solve problems such as uneven brightness and damage to OLED lighting devices, and achieve the effects of improving production yield and improving brightness unevenness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

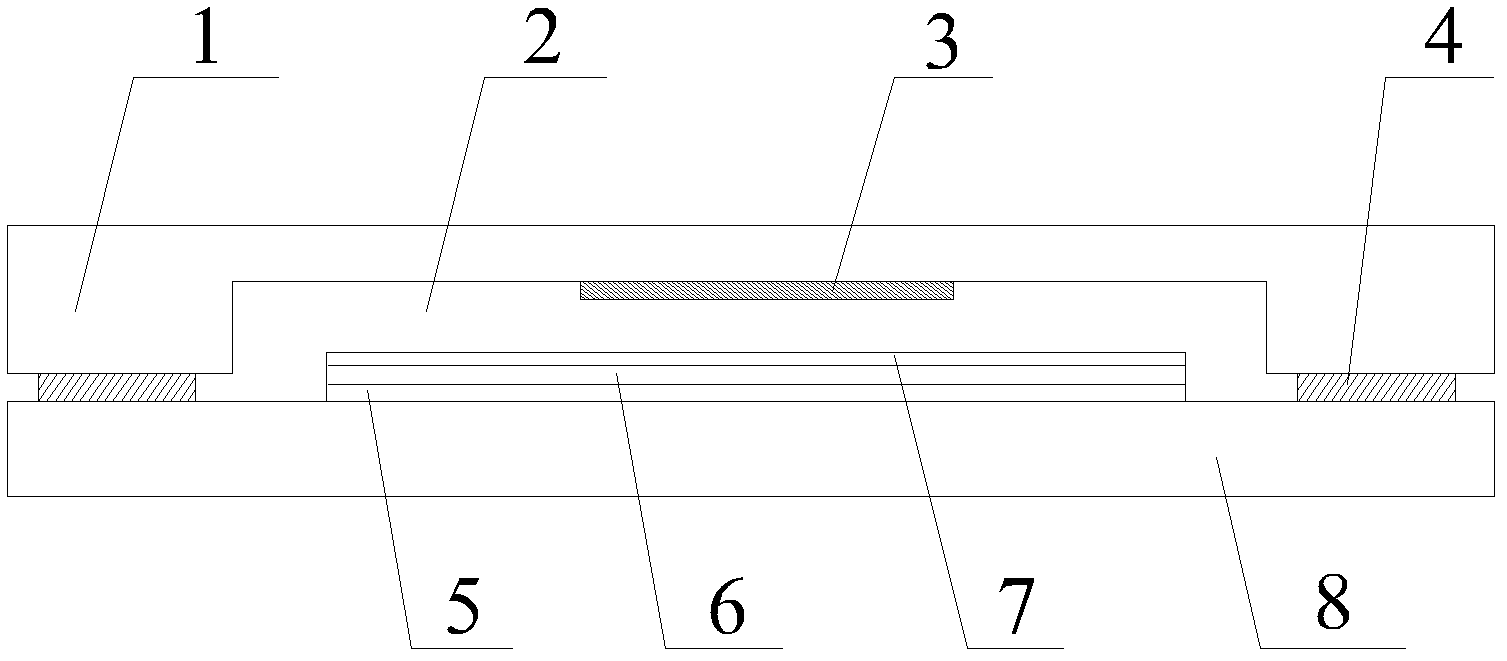

[0037] The OLED lighting device provided by the present invention comprises: an encapsulation back cover and a glass substrate arranged oppositely; a transparent anode, an organic functional layer and a metal cathode are sequentially arranged on the side of the glass substrate facing the encapsulation back cover. Wherein, the top view structural schematic diagram of the transparent anode is shown as Figure 4 As shown, the transparent anode includes: a plurality of mutually independent display unit electrodes (corresponding to light-emitting regions) 15 ; and an auxiliary metal electrode 16 connected to the plurality of mutually independent display unit electrodes 15 .

[0038] The shape of the display unit electrode 15 in the embodiment of the present invention is a square, and the shape of the display unit electrode in other embodiments may also be a triangle, a rectangle, a hexagon or other polygons. A channel electrode 17 is provided on four sides (or surroundings) of the ...

Embodiment 2

[0045] The OLED lighting device provided by the present invention has been described in detail above, and the manufacturing method of the OLED lighting device will be specifically introduced below.

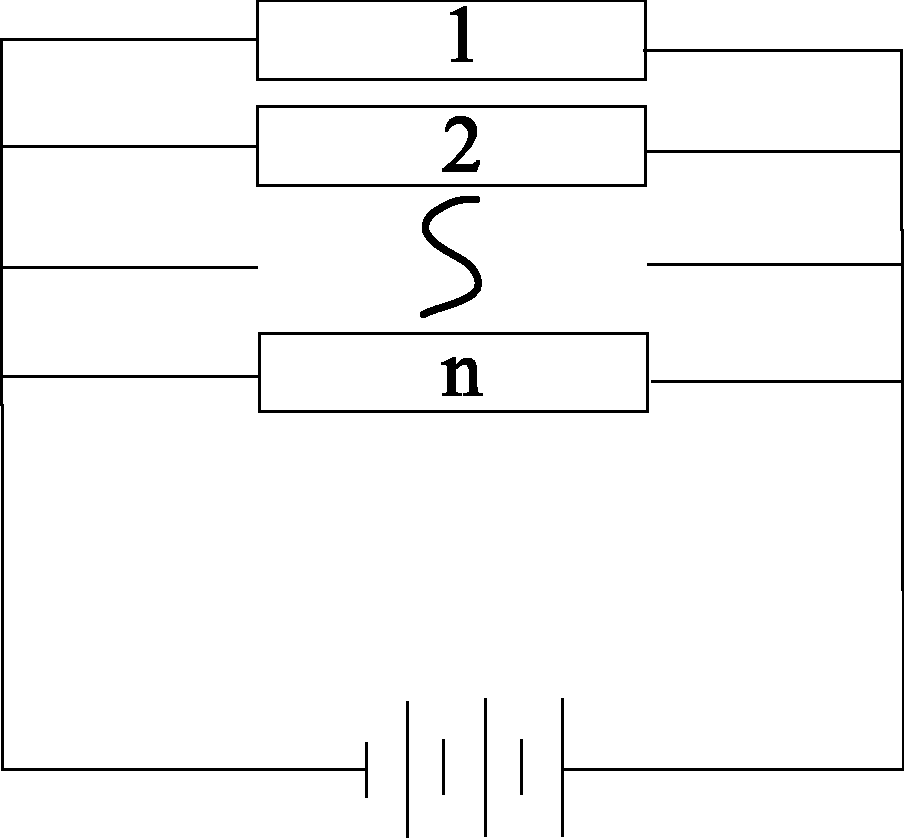

[0046] refer to Figure 6 , Figure 6 It is a schematic flowchart of a method for manufacturing an OLED lighting device provided by an embodiment of the present invention, and the method specifically includes the following steps:

[0047] Step S1: providing a glass substrate.

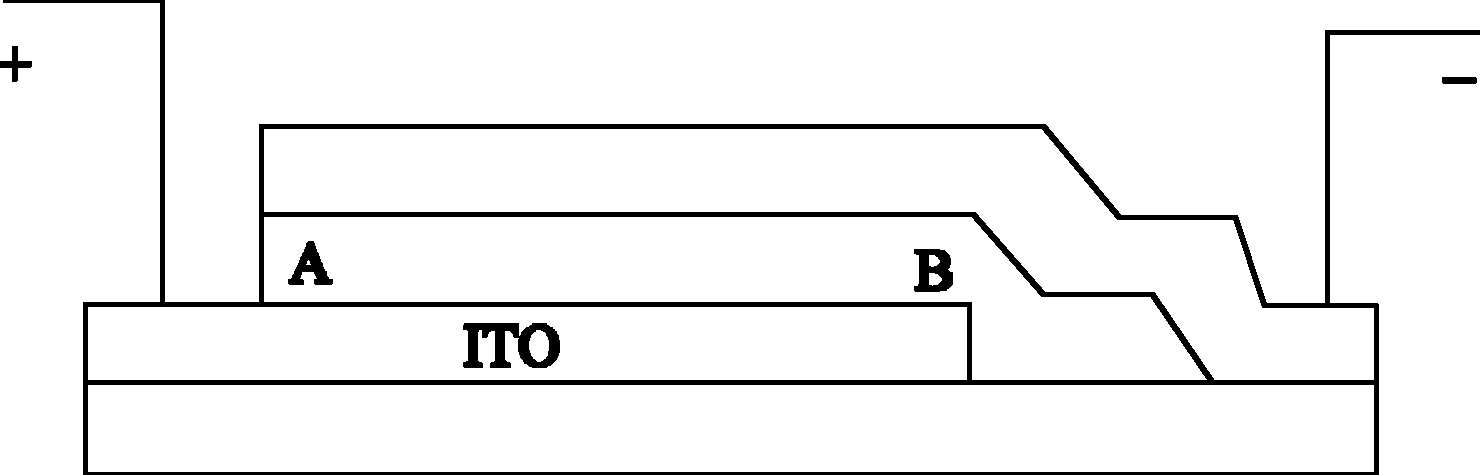

[0048] Step S2: sequentially forming a transparent anode body layer and an auxiliary metal body layer on the glass substrate.

[0049] First, a transparent anode body layer is formed on one side of the glass substrate. The method for forming the transparent anode body layer may include evaporation, thermal spraying, magnetron sputtering or chemical vapor deposition, etc., and the transparent anode body layer is generally an ITO layer. . An auxiliary metal body layer is then formed on the transparent ano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com