Hybrid drive system with hydraulic torque converter

A hydraulic torque converter and hybrid drive technology, which is applied in the field of hybrid drive system, vehicle hybrid drive system, and drive system, can solve the problems that cannot meet the high power requirements of heavy vehicles, and achieve the effect of large power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to understand the technical content of the present invention more clearly, the following examples are given in detail. It should be understood that the examples are only used to illustrate the present invention, not to limit the present invention.

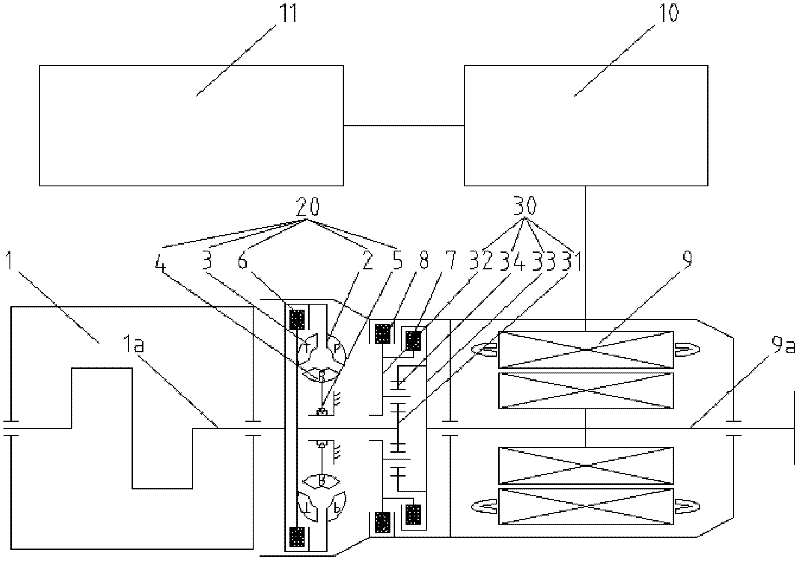

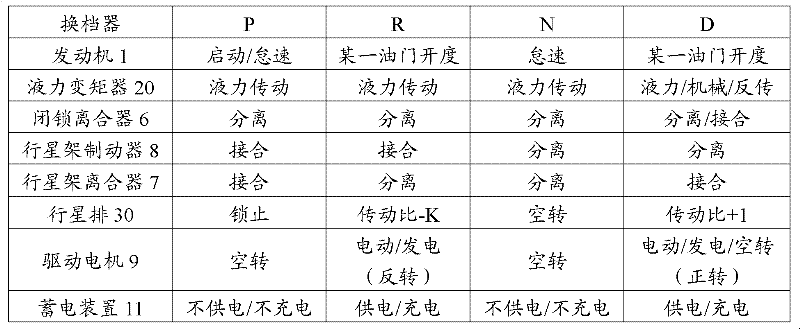

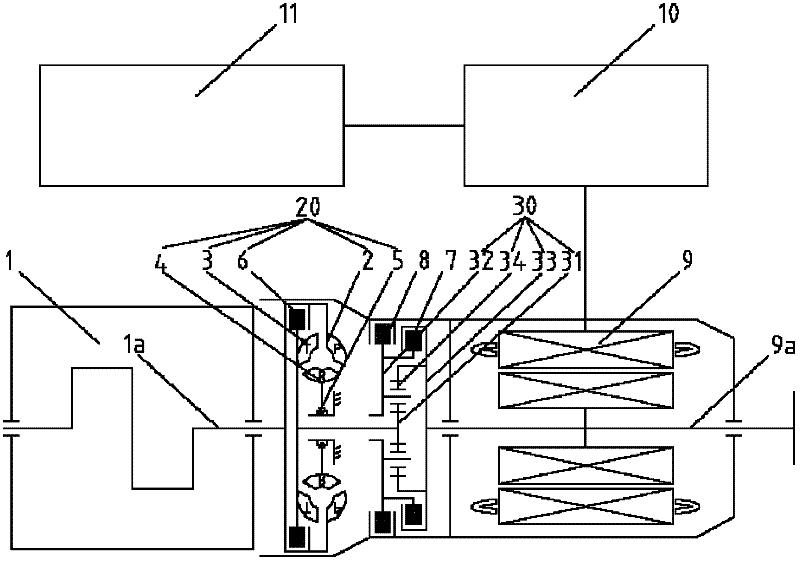

[0025] figure 1 is a schematic structural diagram of a hybrid drive system according to an embodiment of the present invention. refer to figure 1 , the hybrid drive system includes: engine 1, which includes crankshaft 1a; torque converter 20, which includes pump wheel 2, turbine wheel 3, guide wheel 4, guide wheel one-way clutch 5 and lock-up clutch 6; planetary row 30, which Including sun gear 31, planet carrier 32, ring gear 33 and planet gear 34; planet carrier clutch 7, which is used to connect planet carrier 32 and ring gear 33; planet carrier brake 8, which is used to brake planet carrier 32; drive motor 9, which includes the rotor shaft 9a; the drive motor controller 10; and the power storage device 11.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com