Multifunctional heat-proof oil tank

A multi-functional, fuel tank technology, applied in the layout, power plant, transportation and packaging combined with the fuel supply of the internal combustion engine, can solve the problems of environmental pollution, anti-collision, poor explosion-proof effect, poor buffer performance, etc., and achieve good explosion-proof effect. , good thermal insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

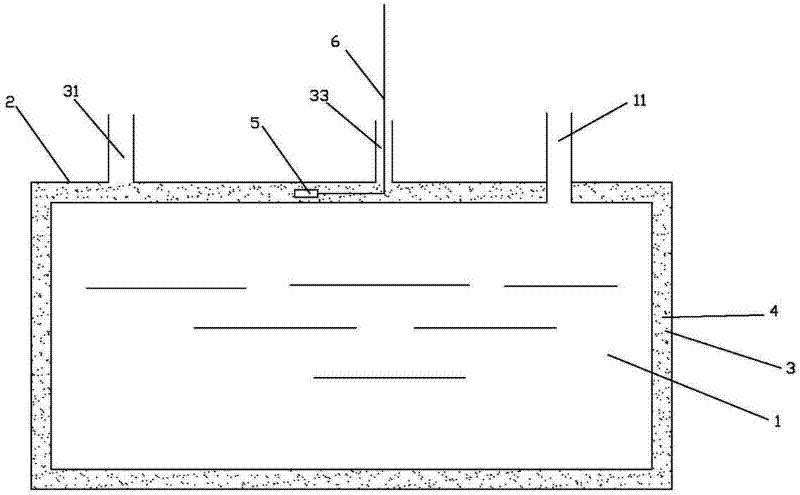

[0026] figure 1 and 2 As shown, the multifunctional heat-proof oil tank of the present invention includes an oil tank 1, an oil port 11 is provided on the oil tank 1, and a layer of heat insulation layer 2 is arranged on the outer surface of the oil tank 1, and the heat insulation layer 2 and the outer surface of the oil tank 1 A sealed cavity 3 is formed between the surface layers. Gas injection and liquid injection ports 31 are arranged on the sealed cavity 3. A heat insulating medium 4 is arranged in the sealed cavity 3. The heat insulating medium 4 is an inert gas. In this embodiment, the inert gas is nitrogen. Also be provided with temperature sensor 5 in sealed cavity 3, this temperature sensor 5 passes through the outlet 33 of sealed cavity 3 by lead wire 6 and is connected with the temperature indicator of console instrument panel, sample can sense sealed cavity by temperature sensor 5 3. The internal temperature is displayed by the temperature indicator, and the dri...

Embodiment 2

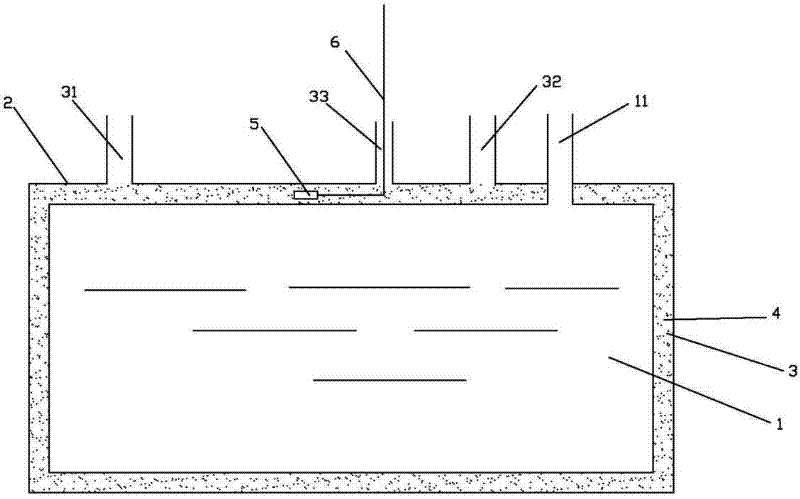

[0028] image 3 and 4 As shown, the heat insulation layer 2 of the present invention has two layers, two sealed cavities 3 are formed between the two layers of heat insulation layers 2, and between the oil tank 1 and the heat insulation layer 2, and each sealed cavity 3 Gas injection and liquid injection port 31 are all provided on the top. The heat insulating medium 4 of the two sealed cavities 3 is respectively an inert gas and water or water and an inert gas from the inside to the outside, and nitrogen is selected as the inert gas. An air outlet 32 is also provided on the outermost sealed cavity 3 of the oil tank 1 , and the heat insulating medium 4 of the sealed cavity 3 is cold and warm air. Others are described in the first embodiment.

Embodiment 3

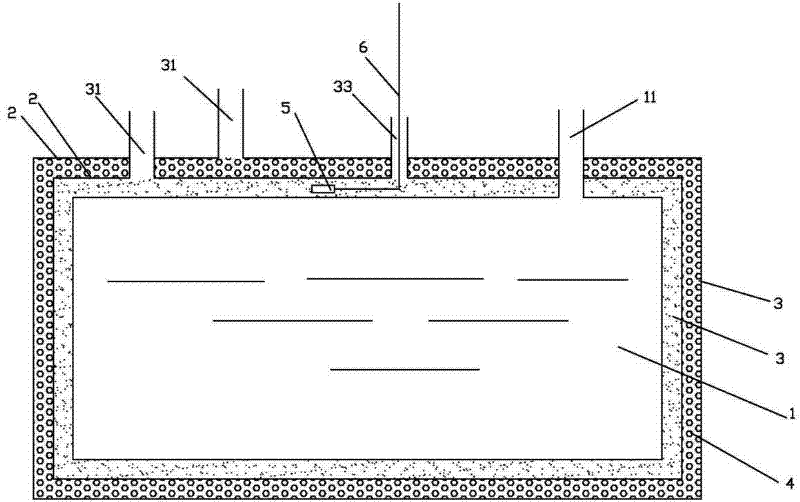

[0030] Figure 5 and 6 As shown, the multifunctional heat-proof oil tank of the present invention includes an oil tank 1, an oil port 11 is provided on the oil tank 1, and three layers of heat insulating layers 2 are arranged on the outer surface of the oil tank 1, and between each layer of heat insulating layers 2, Three sealed cavities 3 are formed between the oil tank 1 and the heat insulating layer 2 , and a heat insulating medium 4 is arranged in the sealed cavities 3 . Gas injection and liquid injection ports 31 are provided on the sealed cavity 3 . The heat insulation medium 4 of the three sealed cavities 3 is inert gas, water, cold air or water, inert gas, cold air or cold air, water, inert gas or inert gas, cold air, water from the inside to the outside. Or water, cold air, inert gas or cold air, inert gas, water, also be provided with air outlet 32 in the sealed chamber 3 that injects cold air. The above-mentioned inert gas is nitrogen. An air outlet 32 is al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com