Corrugated steel plate aseismic shear wall

A technology of corrugated steel plate and shear wall, applied in the direction of wall, shockproof, building components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Further description will be made below in conjunction with the embodiments and accompanying drawings.

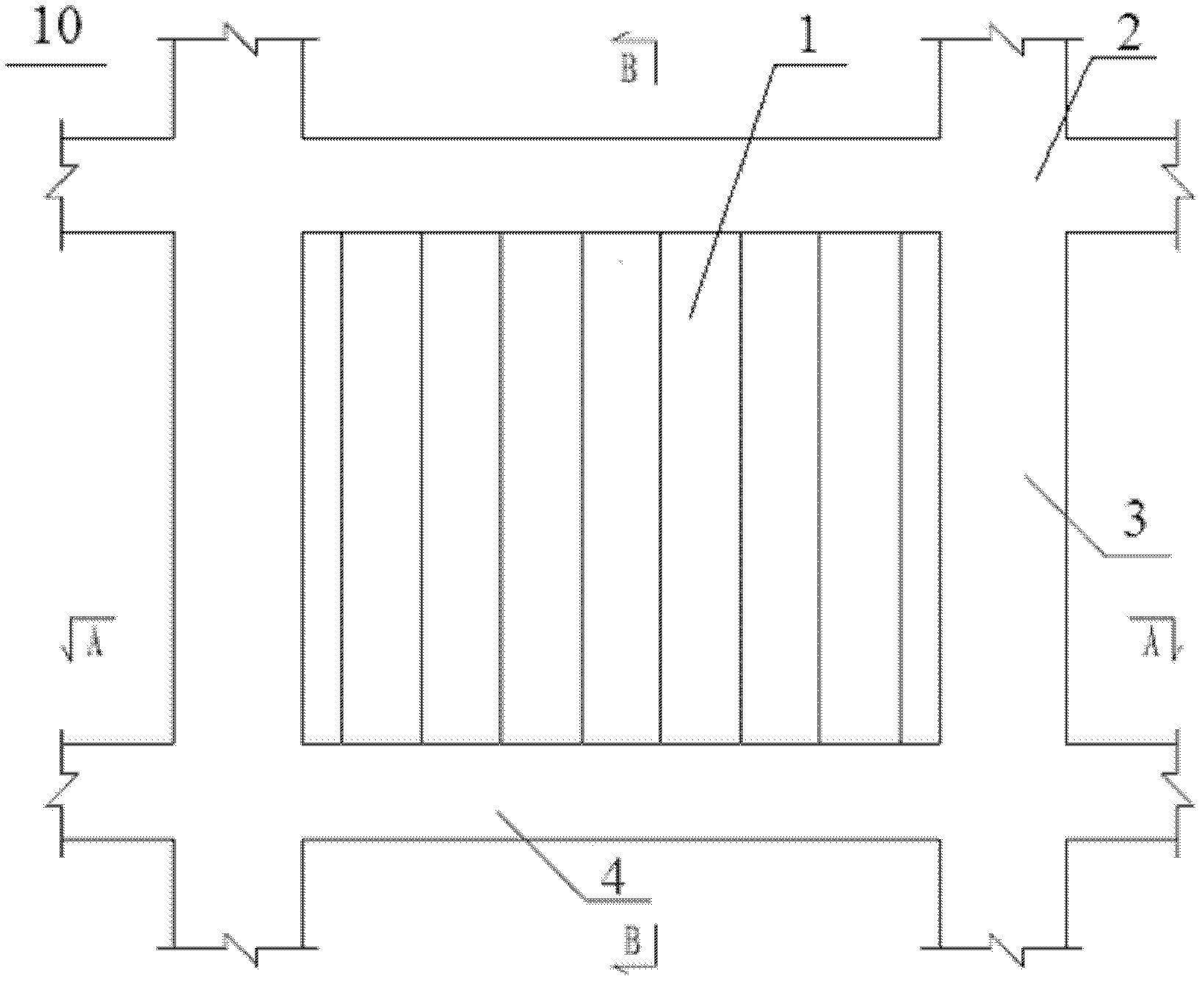

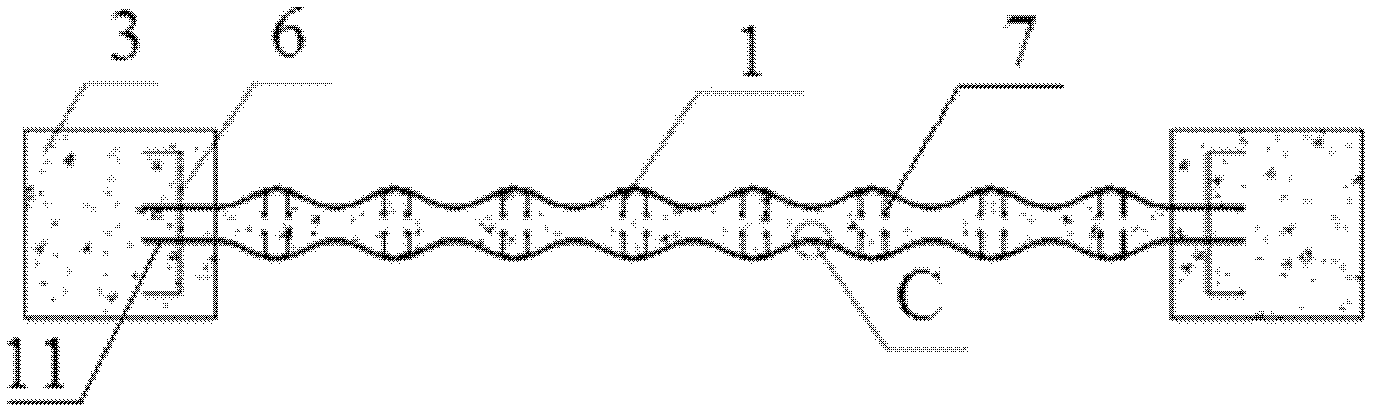

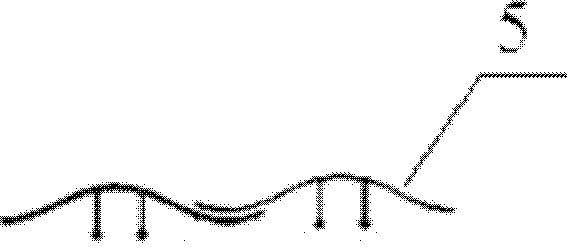

[0023] Such as figure 1 , figure 2 and image 3 As shown, the aseismic shear wall 10 of corrugated steel plates includes two corrugated steel plates 1. The two corrugated steel plates are arranged opposite to each other, and the corrugations differ by 180 degrees. A number of studs 7 are welded on the inner sides of the two corrugated steel plates. The concrete 8 is connected together, and the edge 11 of the two corrugated steel plates is connected with the edge frame 2 . The edge frame 2 is a concrete frame and is composed of upper and lower beams 4 and left and right columns 3 . The connection structure between the edge 11 of the two corrugated steel plates and the edge frame 2 is that the edges 11 of the two corrugated steel plates are respectively provided with reinforcement holes, and the penetrating steel bars 6 in the beam 4 and the column are connected th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com