Patents

Literature

36results about How to "Reduce lashing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

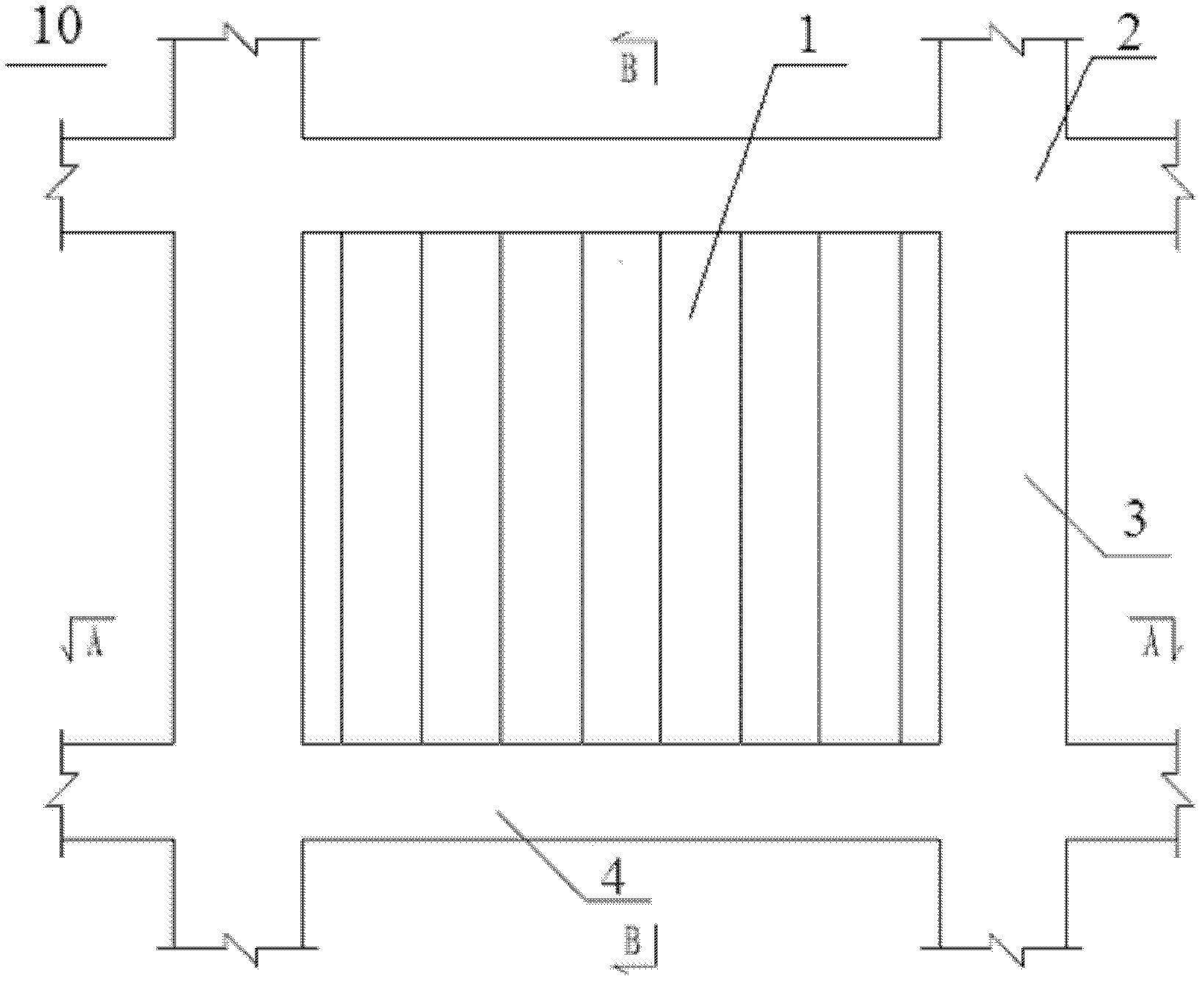

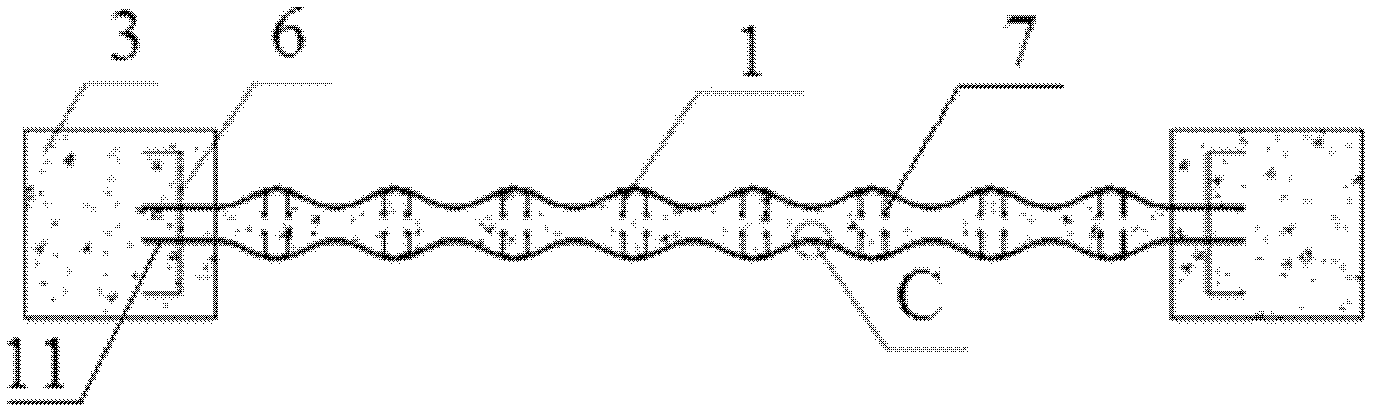

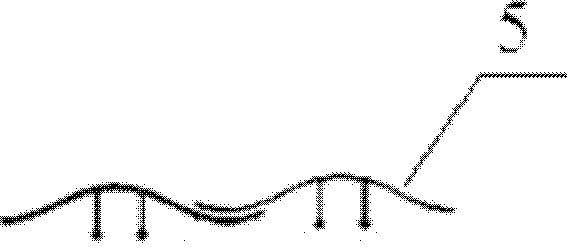

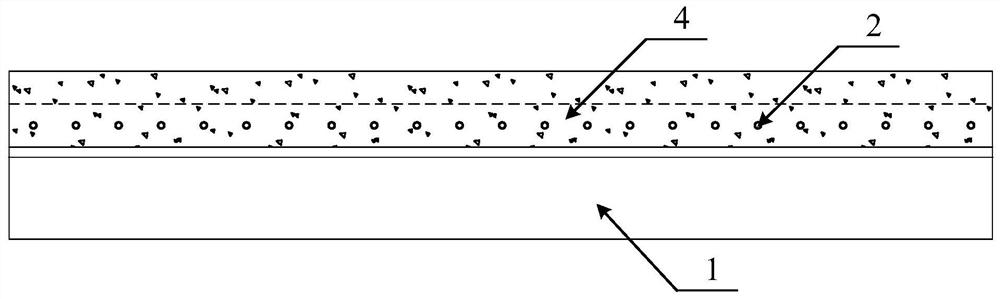

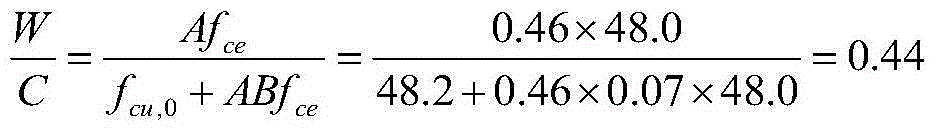

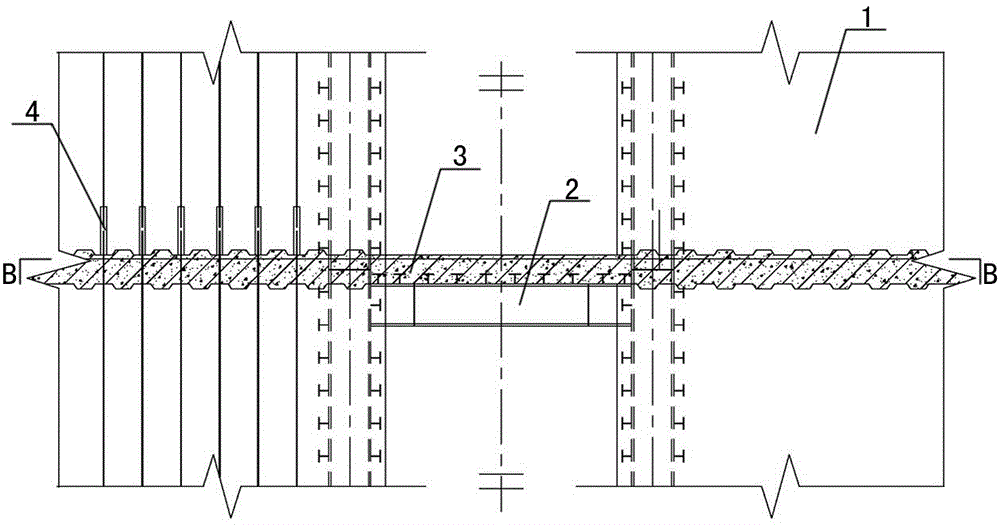

Corrugated steel plate aseismic shear wall

InactiveCN102359205ALow costEnhance mutual binding forceWallsShock proofingMaterials scienceShear wall

The invention relates to a corrugated steel plate aseismic shear wall which comprises two corrugated steel plates, wherein the two corrugated steel plates are oppositely arranged, the corrugation difference of 180 degrees is realized, a plurality of protrudent steel members are distributed on the inner sides of the two corrugated steel plates, the two corrugated steel plates are connected together by pouring concrete, and the edges of the two corrugated steel plates are connected with an edge framework. The corrugated steel plate aseismic shear wall is high in bearing performance, strong in energy dissipation capacity and convenient to construct.

Owner:JIANGSU TRANSPORTATION RES INST CO LTD

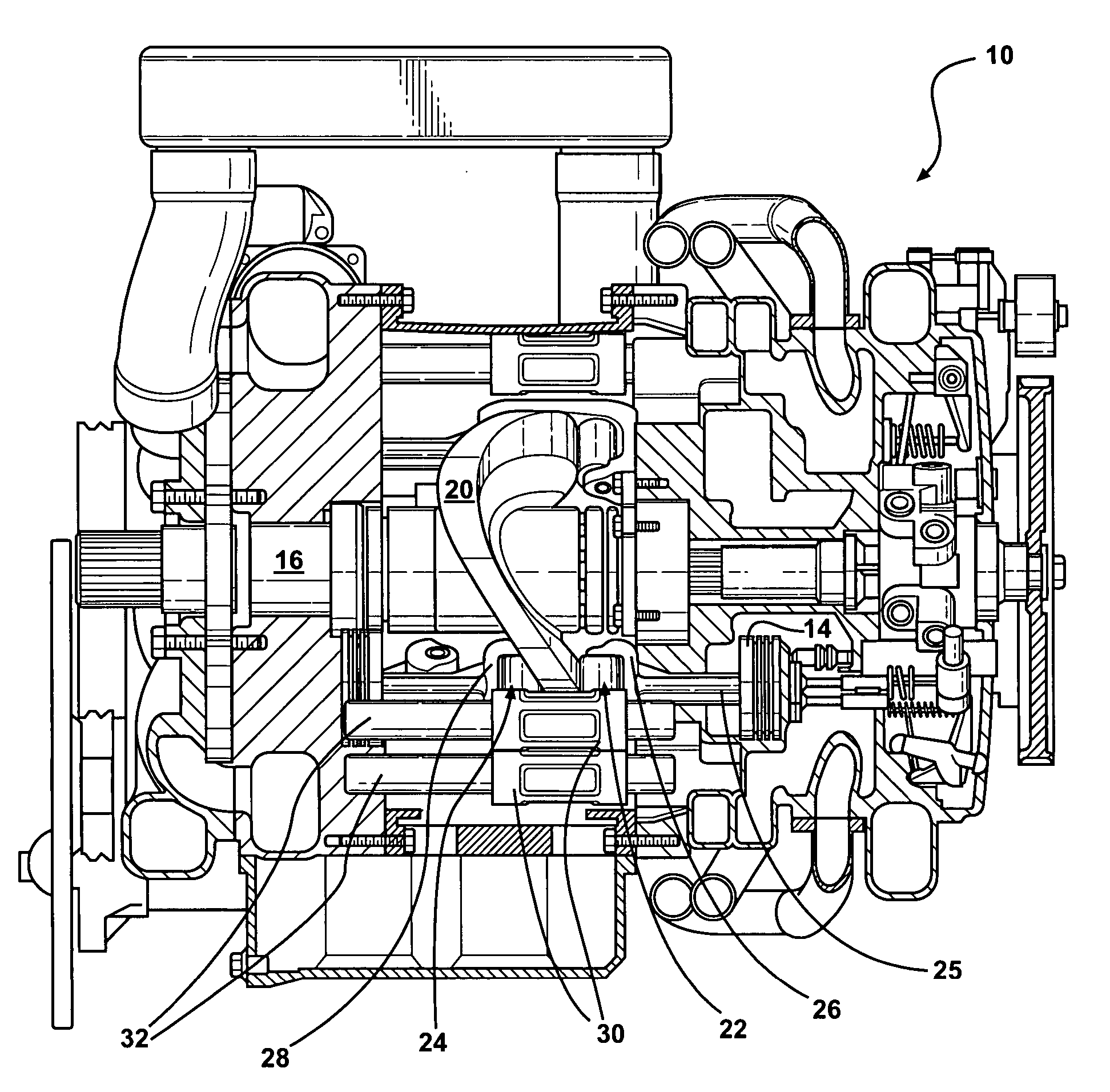

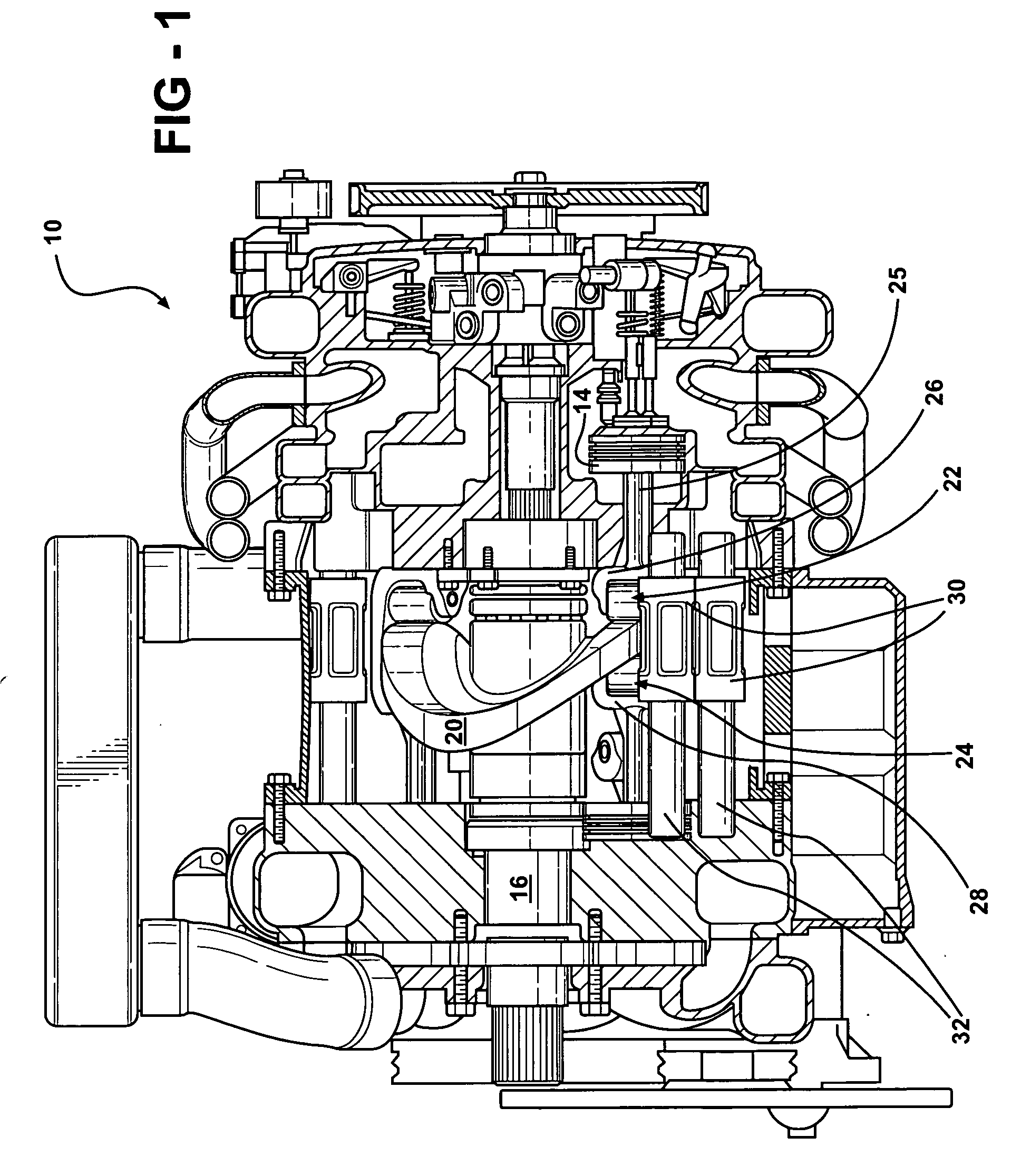

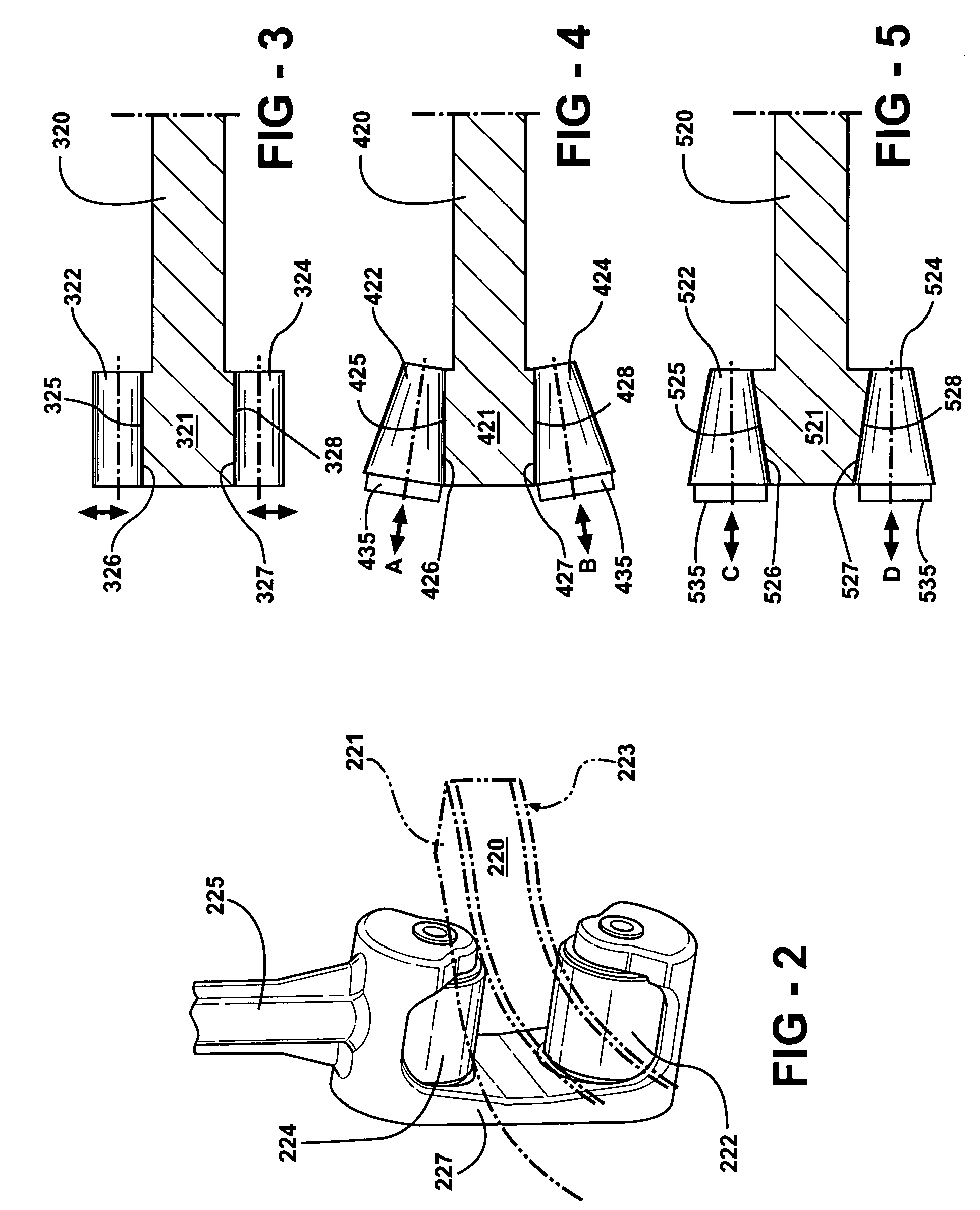

Lash adjustment for piston rollers

A lash adjustment system for a roller is provided which includes a cam plate surface and a frustoconically shaped roller in mechanical communication with the surface. Means for moving the roller relative to the surface are included to urge the roller inwardly with respect to the cam plate in order to reduce lash.

Owner:THOMAS C RUSSELL

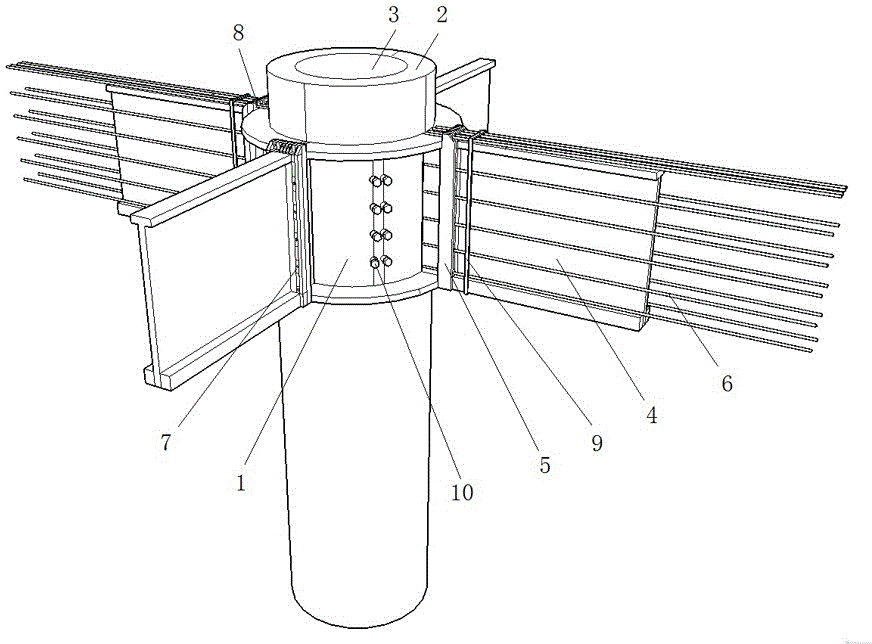

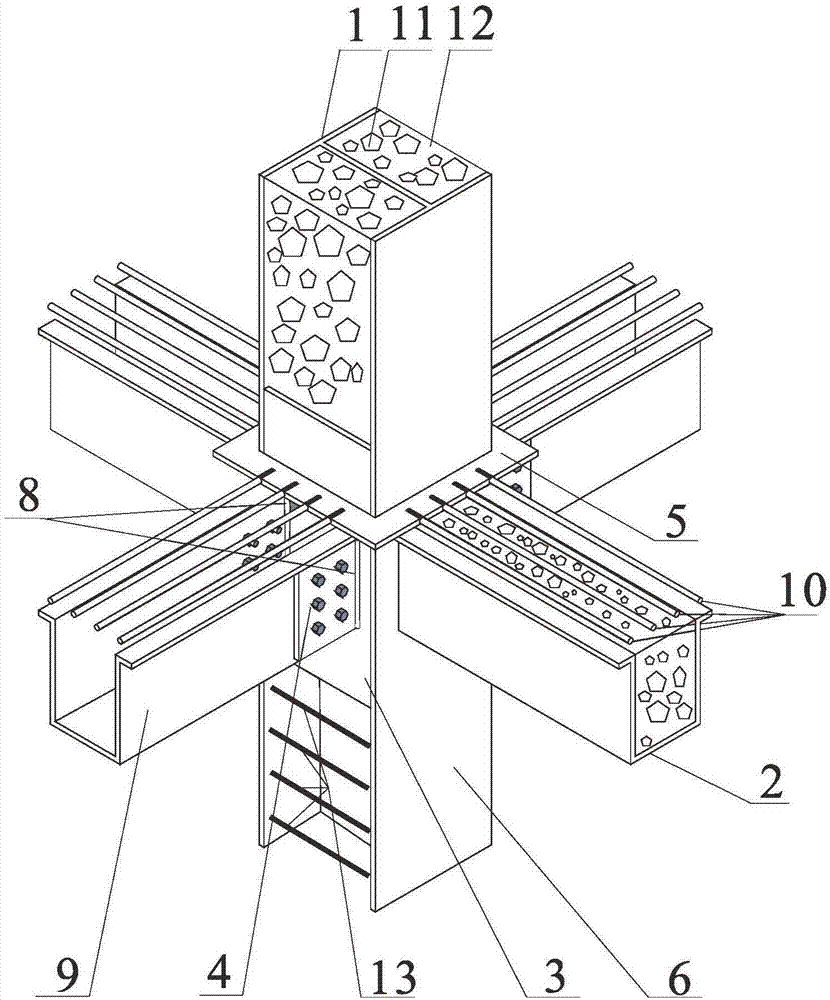

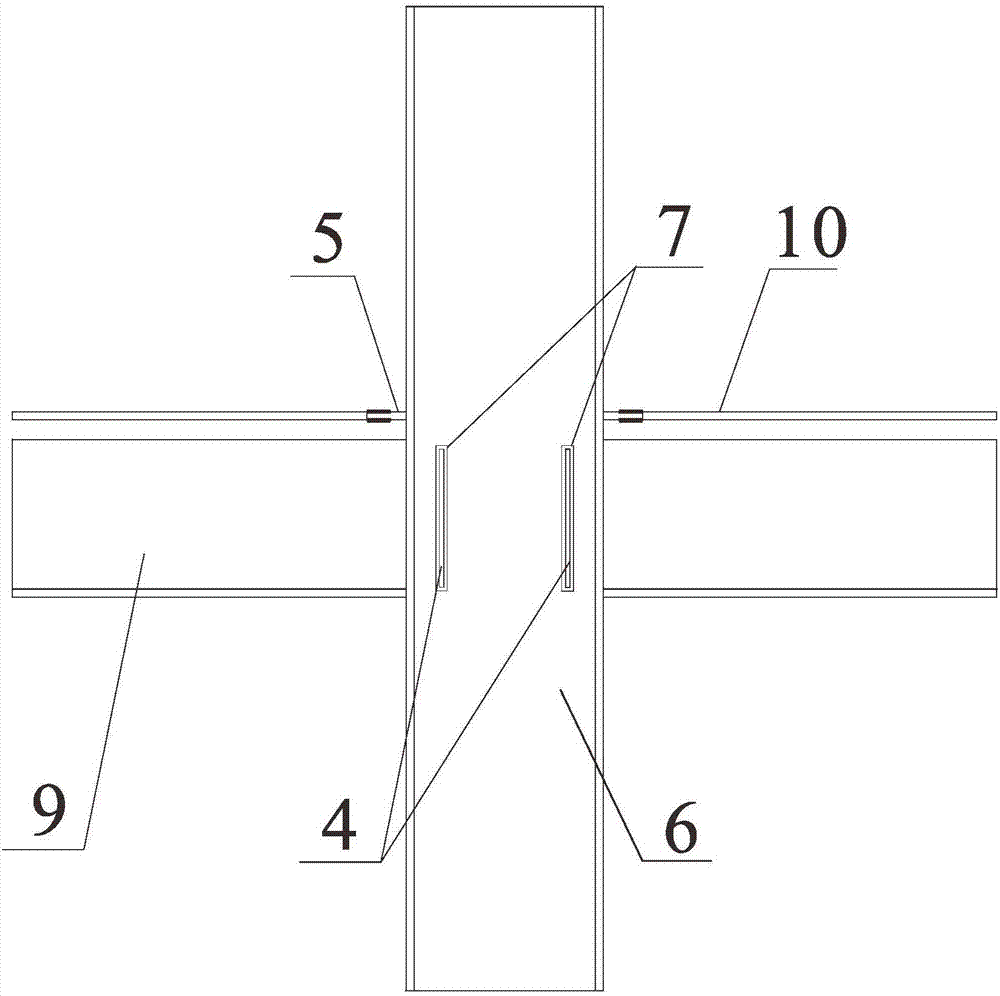

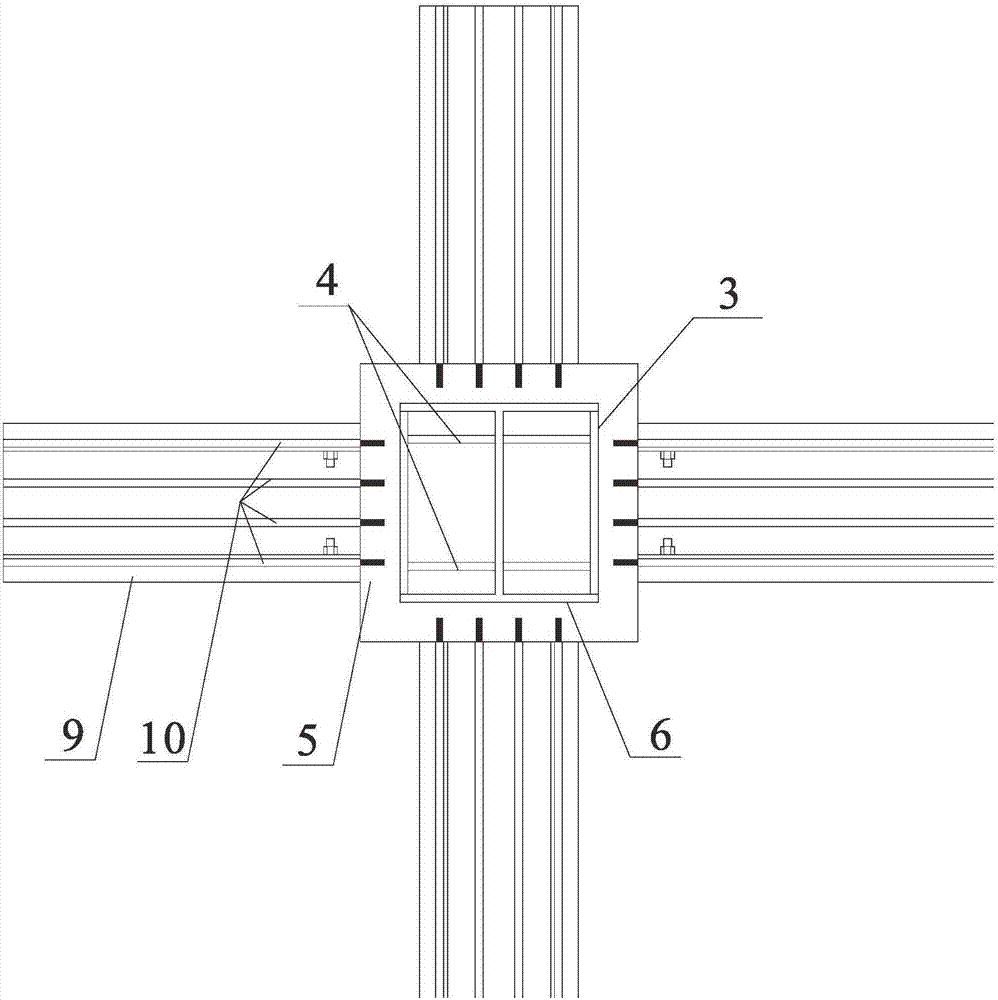

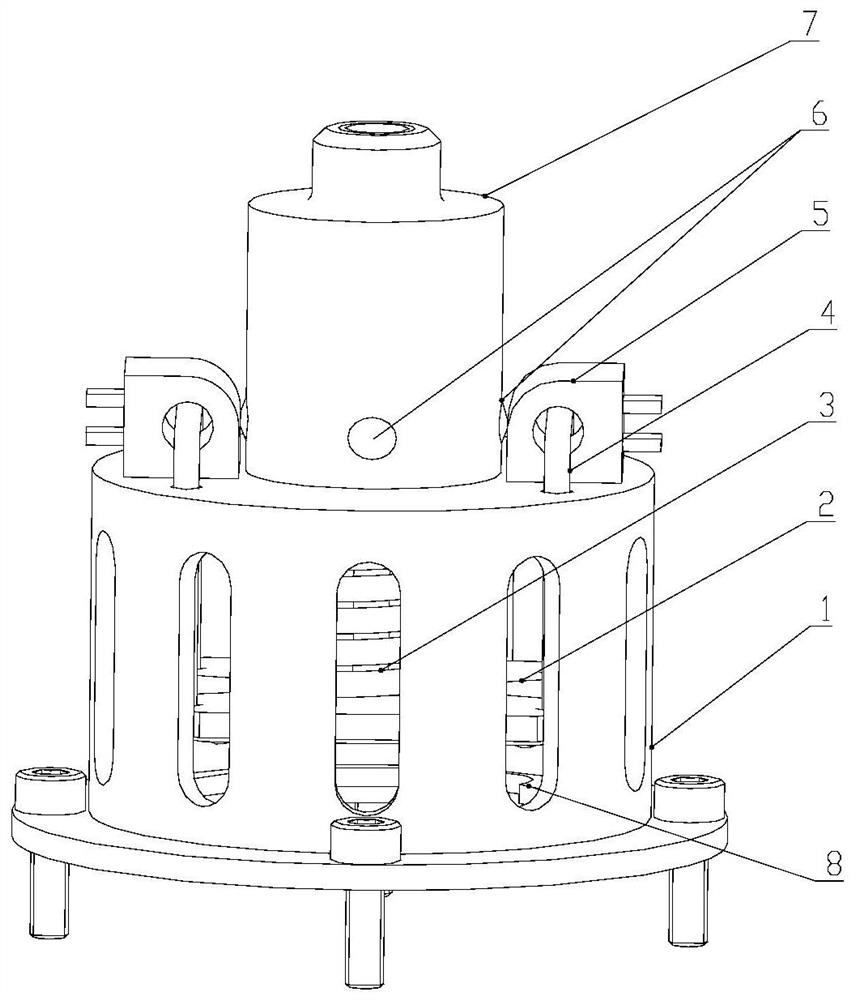

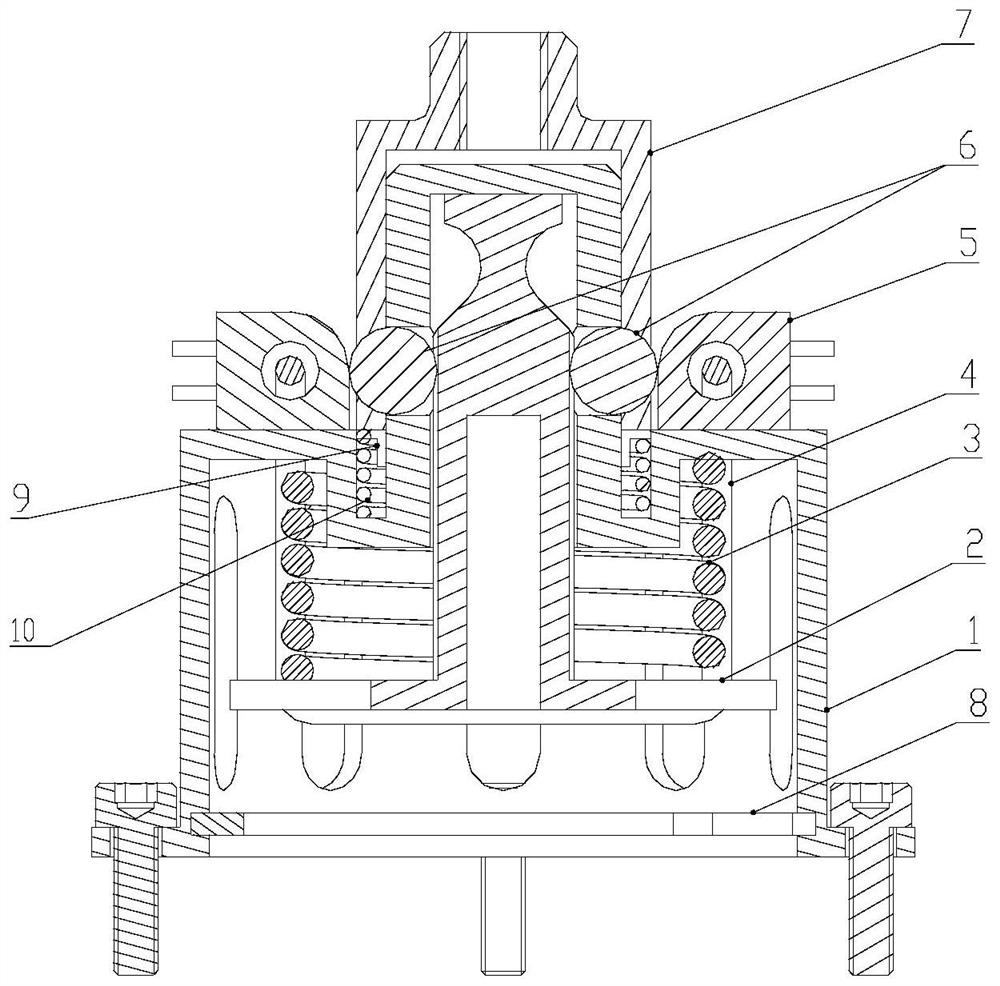

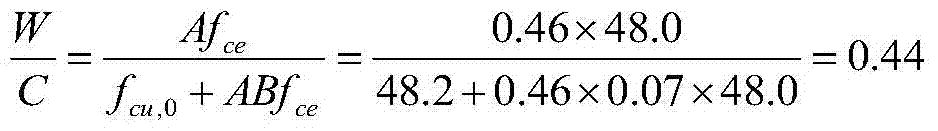

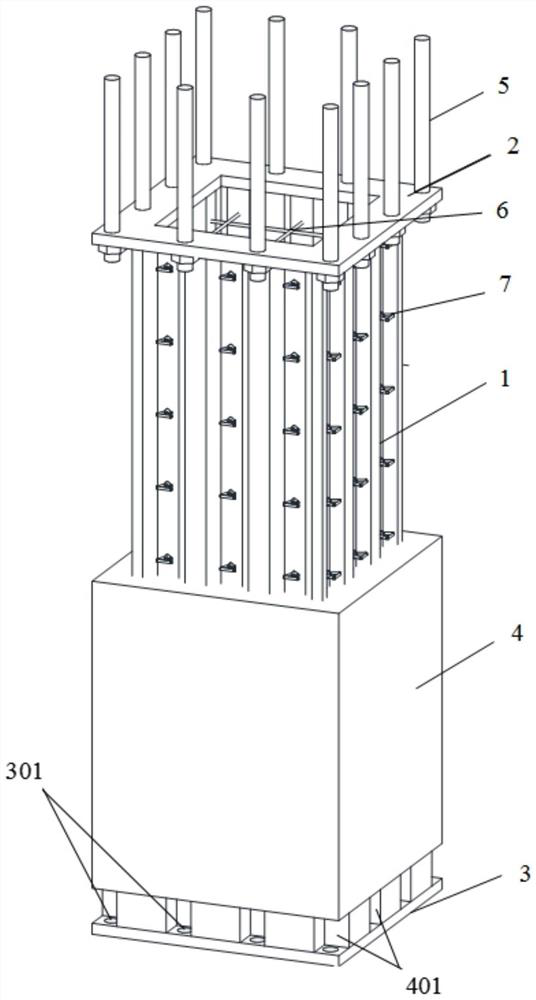

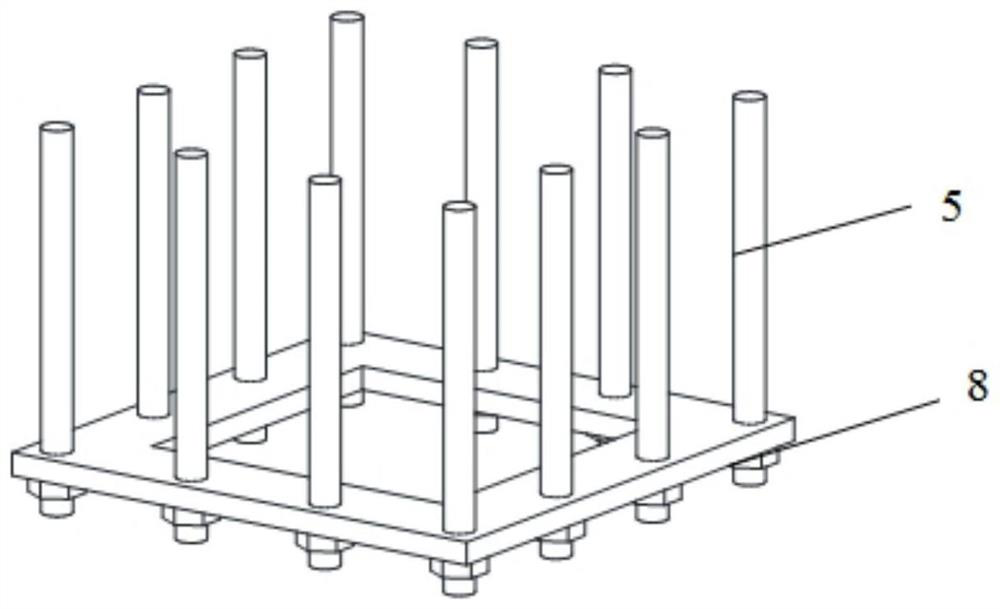

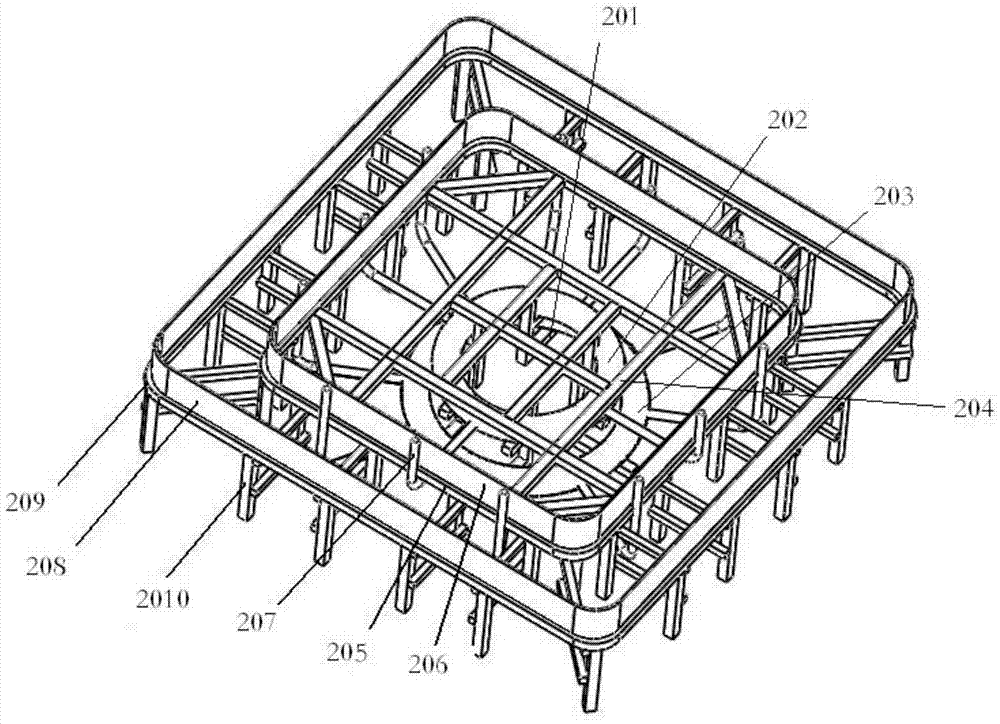

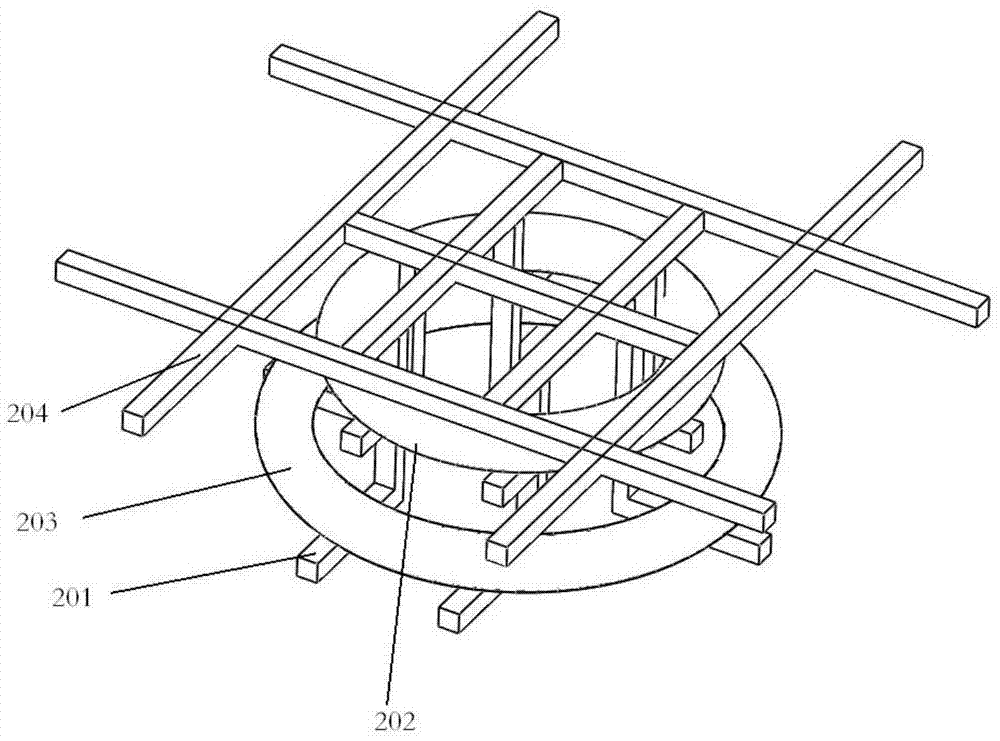

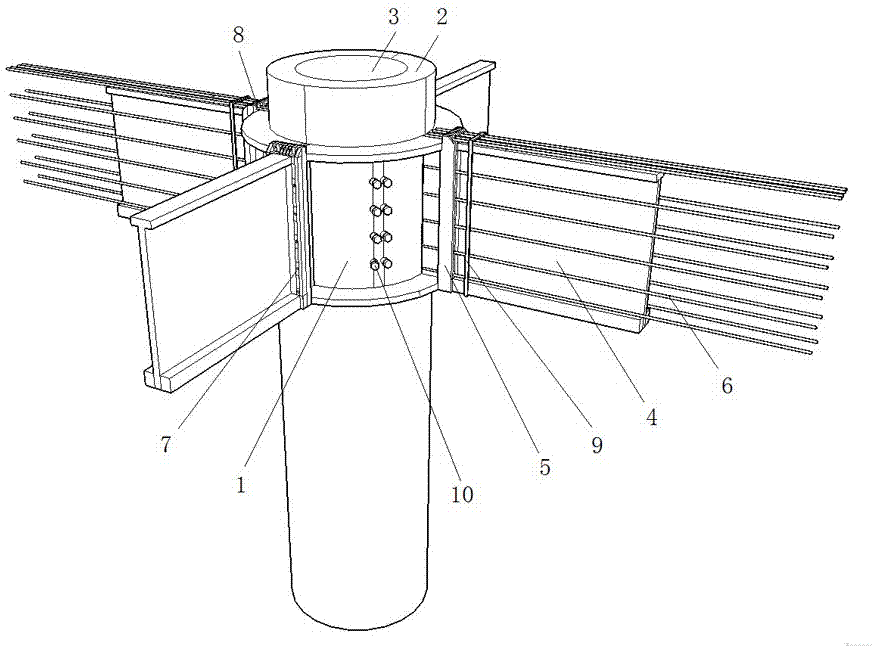

Solderless assembly type steel pipe concrete beam column node and construction method thereof

InactiveCN105804246AReduce the impactSimple structural designBuilding constructionsConcrete beamsEngineering

The invention relates to a solderless assembly type steel pipe concrete beam column node, which comprises a steel pipe concrete column, wherein an annular sleeve is arranged outside the steel pipe concrete column; a plurality of reinforced concrete beams are annularly arranged at the circumferential side of the annular sleeve. The invention also relates to a construction method of the solderless assembly type steel pipe concrete beam column node. The solderless assembly type steel pipe concrete beam column node and the construction method have the advantages that the structure design is simple, compact and reasonable; all mechanical properties of the node are met; the structure assembly is realized; the assembling speed of components is accelerated; the requirements and the characteristics of an assembly type system are fully met.

Owner:FUZHOU UNIV

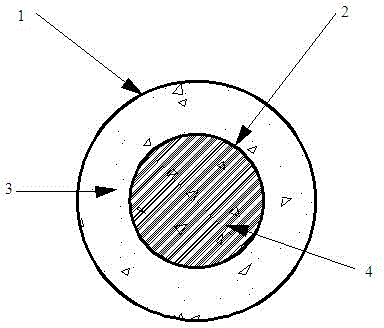

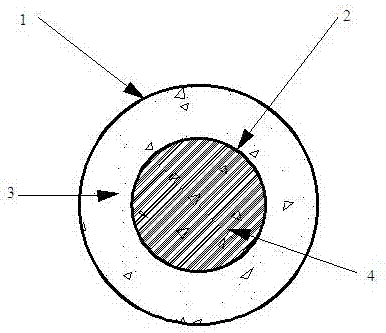

Dual steel pipe-encased concrete anti-seismic column with built-in rubber mixture and construction method

The invention discloses a dual steel pipe-encased concrete anti-seismic column with a built-in rubber mixture. The dual steel pipe-encased concrete anti-seismic column comprises round-in-round, square-in-square, round-in-square, square-in-round, rectangle-in-rectangle cross section forms, is composed of an outer steel pipe, an inner steel pipe, interlayer concrete and the rubber mixture; the inner and outer steel pipes are in fixed connection through welding or a bolt; and the interlayer concretely is disposed between the two steel pipes, the rubber mixture is packed in the inner steel pipe, and the interlayer concrete is self-compacting concrete. The rubber mixture is in the inner-layer steel pipe, has extremely good energy-consumption damping effect, is capable of effectively absorbing earthquake energy, and also is capable of effectively preventing fires. The dual steel pipe-encased concrete anti-seismic column with the built-in rubber mixture is relatively light in deadweight. The anti-seismic column is a main member of a framework structure of high-rise and wide-span buildings, and has the characteristics of high bearing capacity, light weight, good plasticity and toughness, good impact resistance and fatigue resistance, excellent earthquake-proof performance, good endurance and the like.

Owner:SHENYANG JIANZHU UNIVERSITY

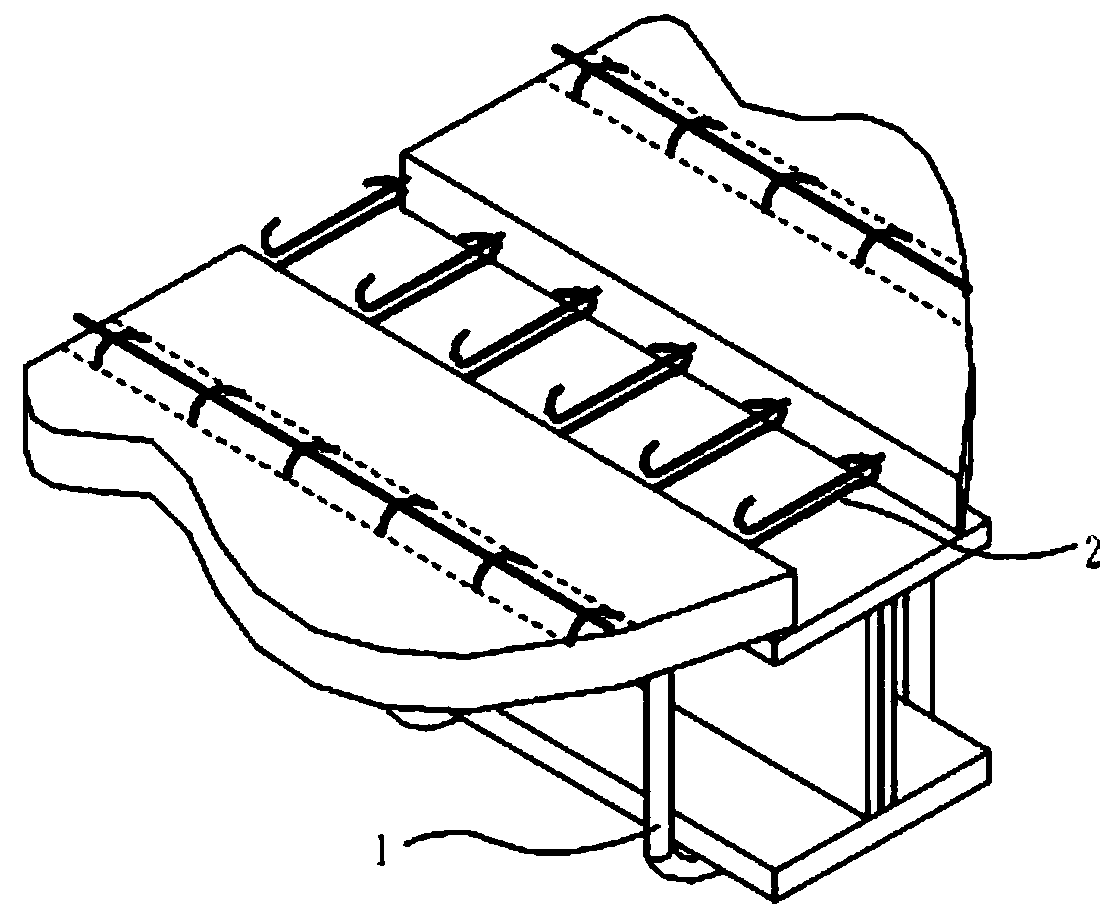

Regenerative block concrete connecting joint provided with H-shaped steel and U-shaped steel

PendingCN107574930APower transmission scienceTake advantage ofBuilding constructionsSolid waste managementSheet steelRebar

The invention discloses a regenerative block concrete connecting joint provided with H-shaped steel and U-shaped steel. The regenerative block concrete connecting joint includes a partial outsourcingH-shaped steel combined column provided with the H-shaped steel, a complete outsourcing U-shaped steel combined beam arranged horizontally in a crossed shape, two first rectangular steel plate connecting parts which are parallel to an H-shaped steel web plate, two second rectangular steel plate connecting parts which are perpendicular to the H-shaped steel web plate and a square outer ring plate with a threaded sleeve. According to the regenerative block concrete connecting joint, on the one hand, because no dense piercing parts are arranged in a joint core area, the problem of put construction of waste concrete blocks is solved, and in addition, the complete outsourcing U-shaped steel combined beam is used, so that the utilization ratio of waste concrete of a structural system can be significantly improved; and on the other hand, outsourcing profiled steel is used in a bean-column structure, so that the processes of steel bar binding and formwork erecting and dismantling can be reduced, meanwhile, a web plate of the U-shaped steel can directly penetrate through the partial outsourcing H-shaped steel combined column, beam shear force and bending moment are transferred better, and continuity of force transferring and safety of the joint are ensured.

Owner:SOUTH CHINA UNIV OF TECH

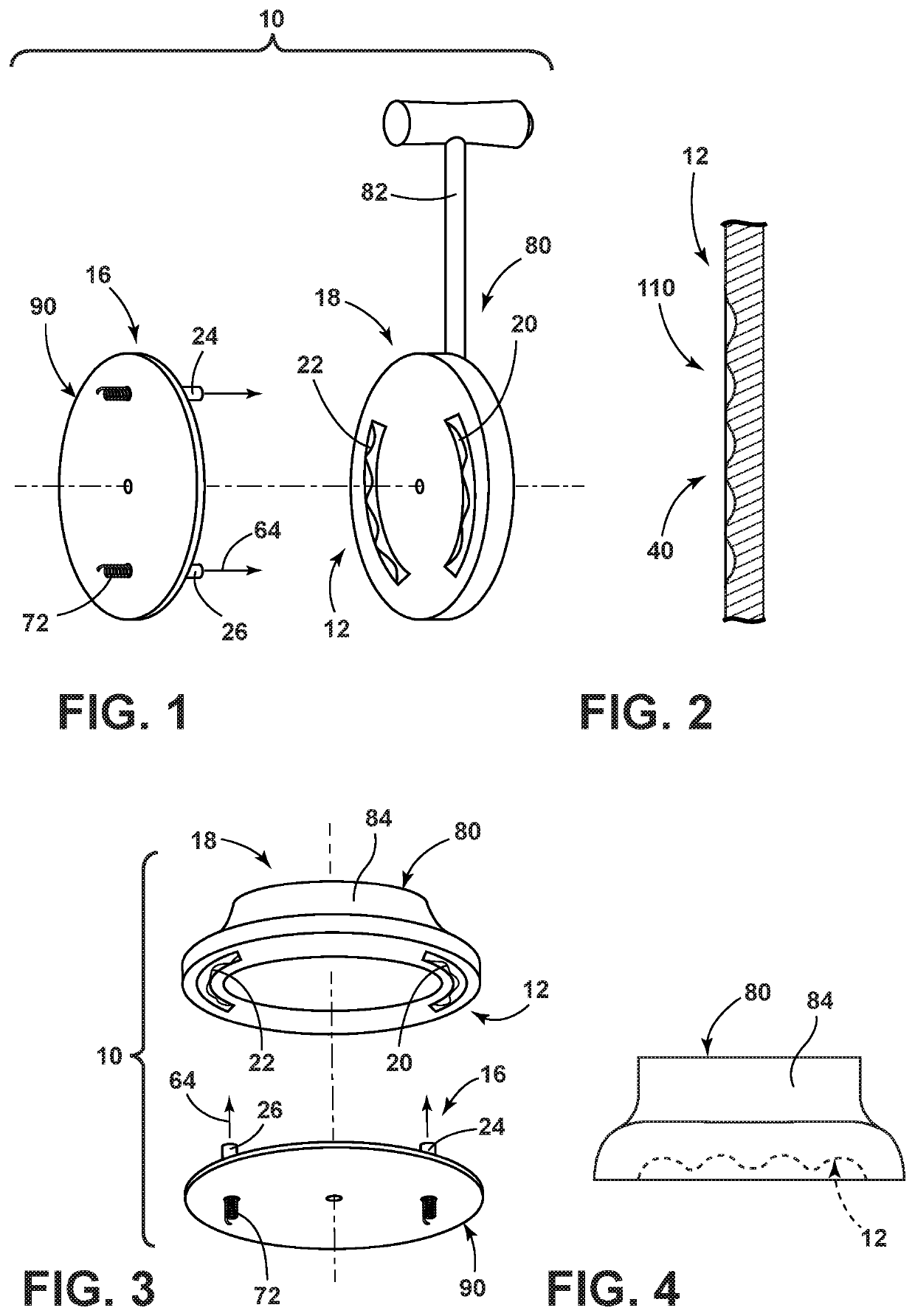

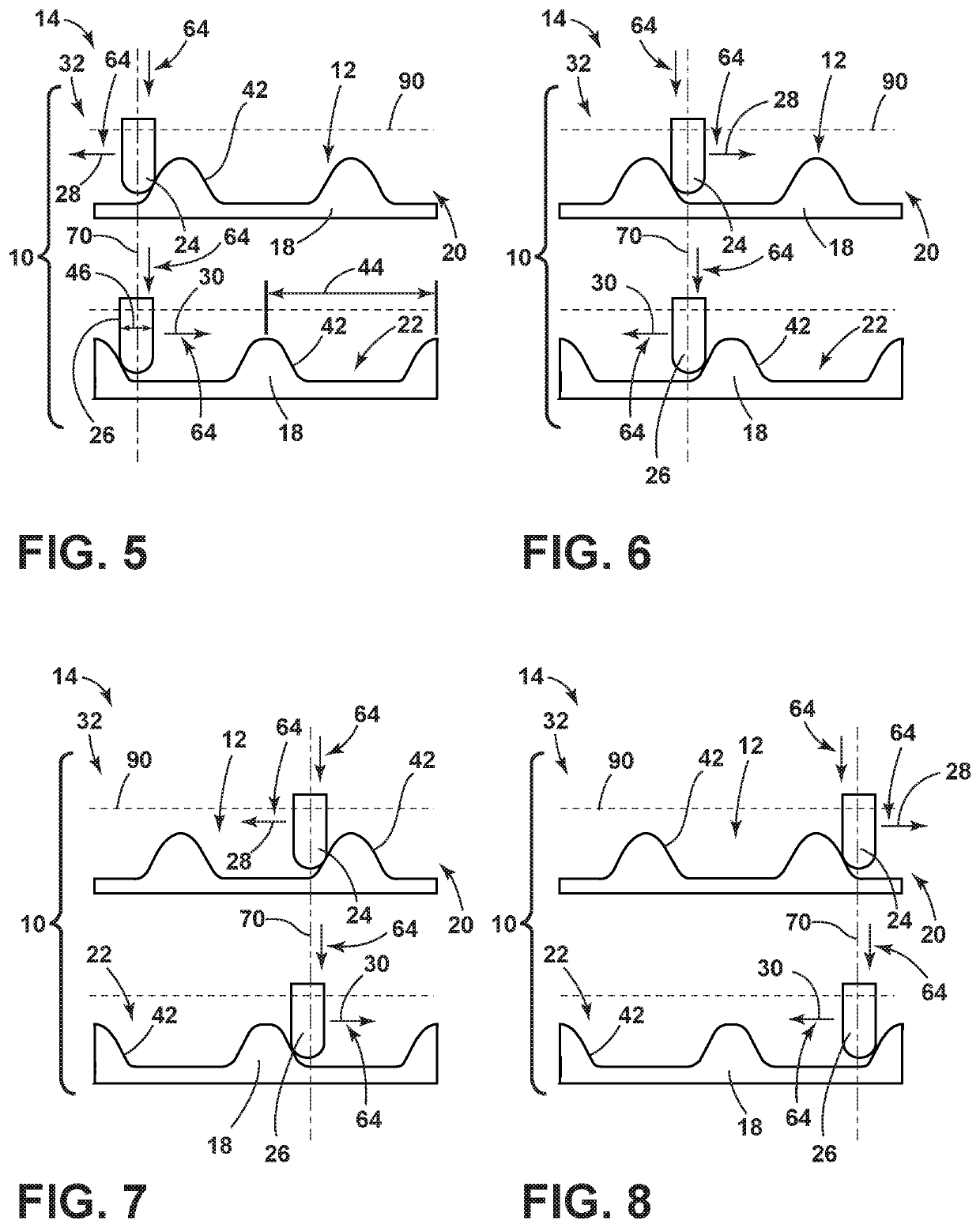

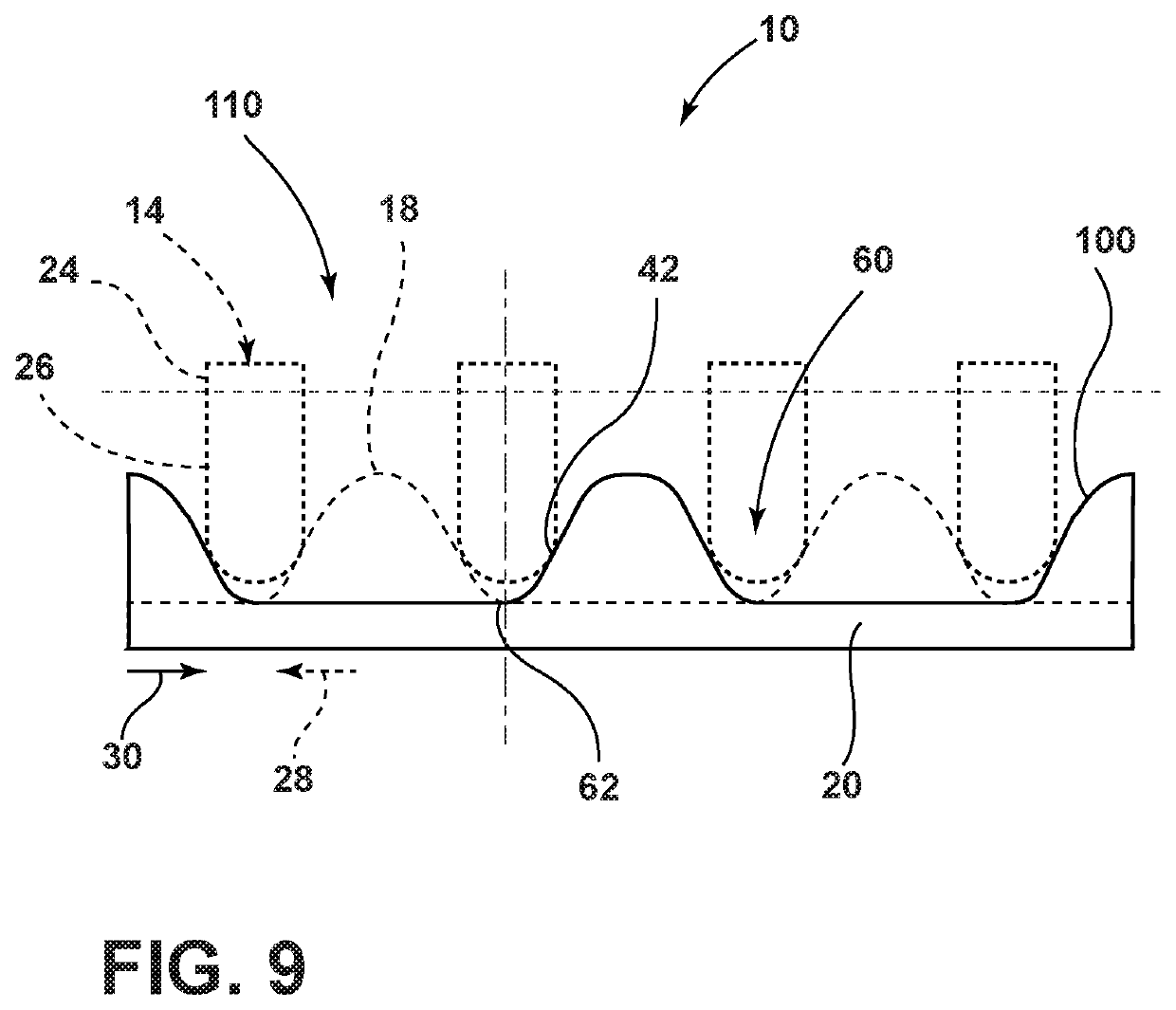

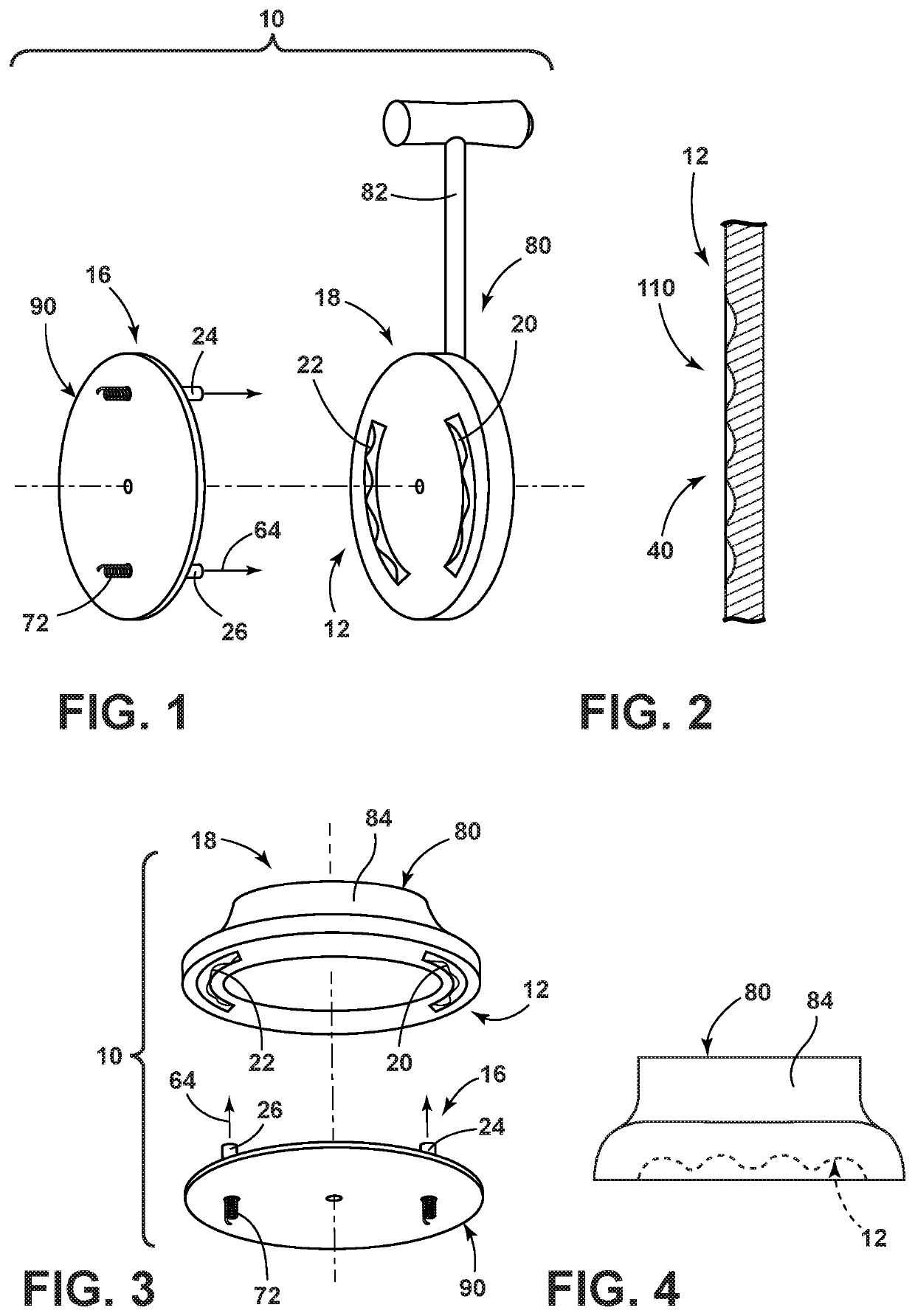

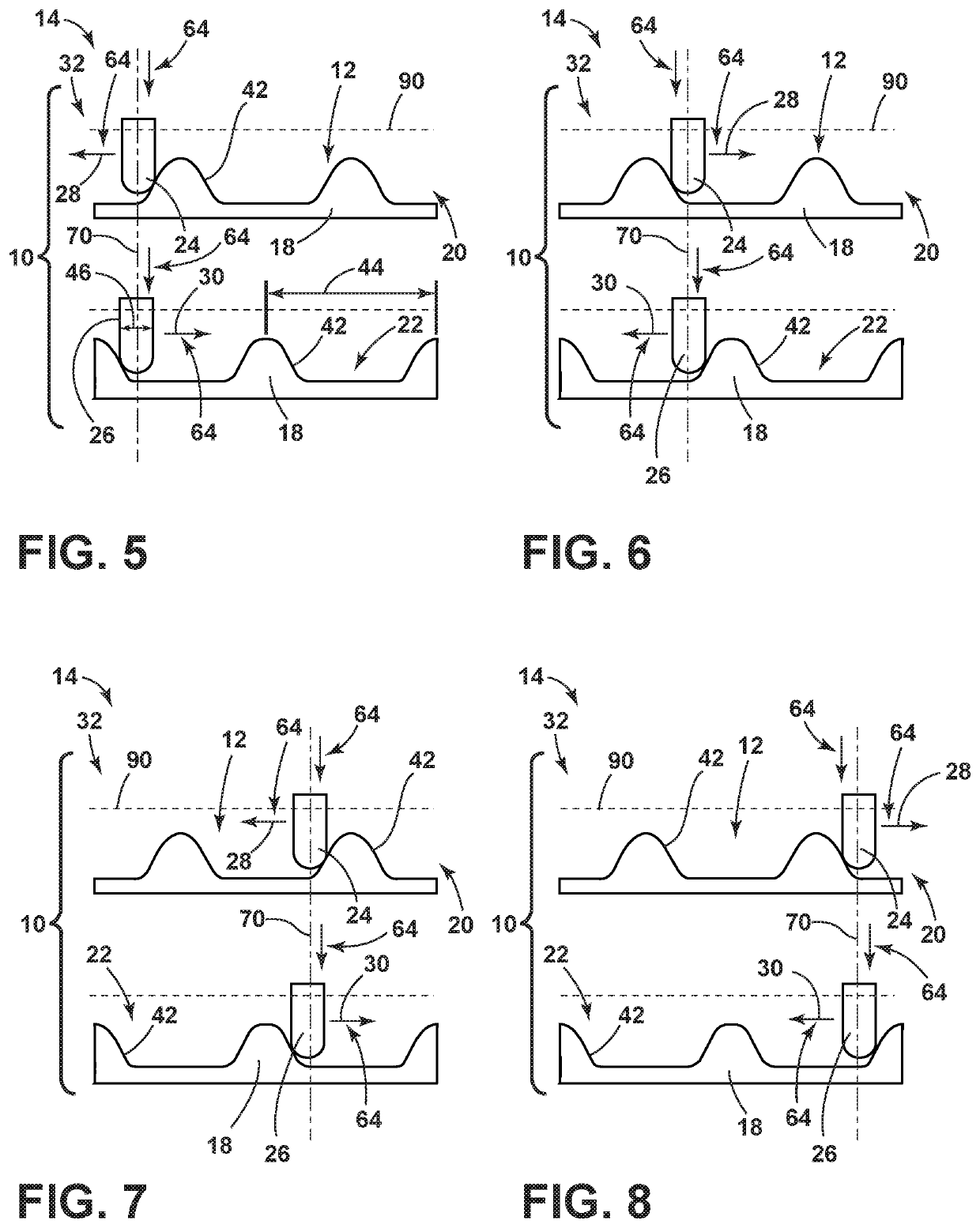

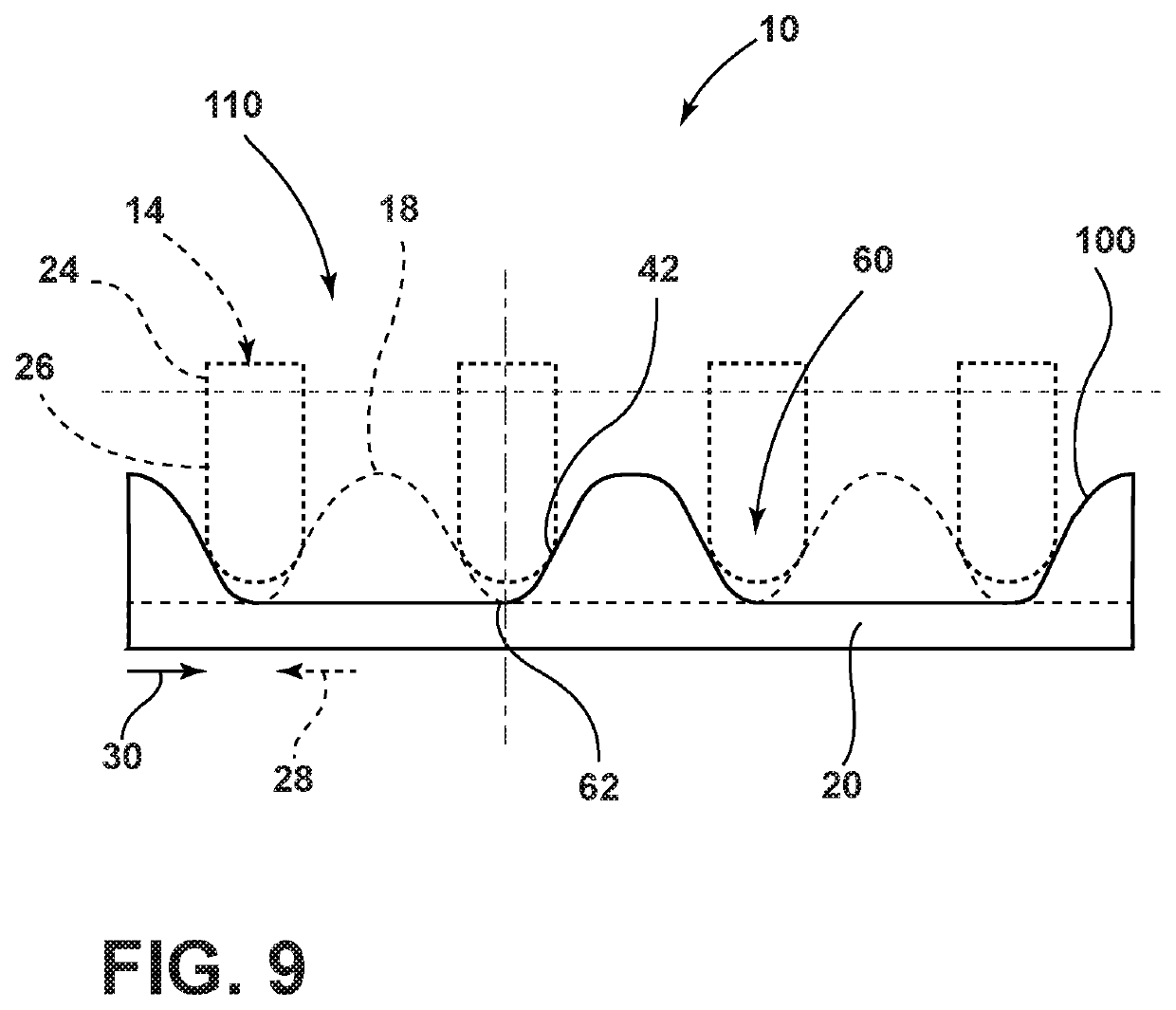

Transmission shifter with improved feel positioner

A selector apparatus comprises a shift lever operably supported on a base for movement between gear positions, and a feel positioner mechanism with offset detent members, where a first detent engages first undulations for biasing the shift lever toward a center of a selected gear position from a first direction, and a second detent engages second undulations for biasing the selector lever toward the center of the selected gear position from a different second direction to the common center point. By the arrangement, the first and second undulations define opposing angled slopes toward the common center point. This allows the undulations to be designed to provide any desired level of biasing force toward the center point without the limitations of a single undulation defining the center point.

Owner:GHSP

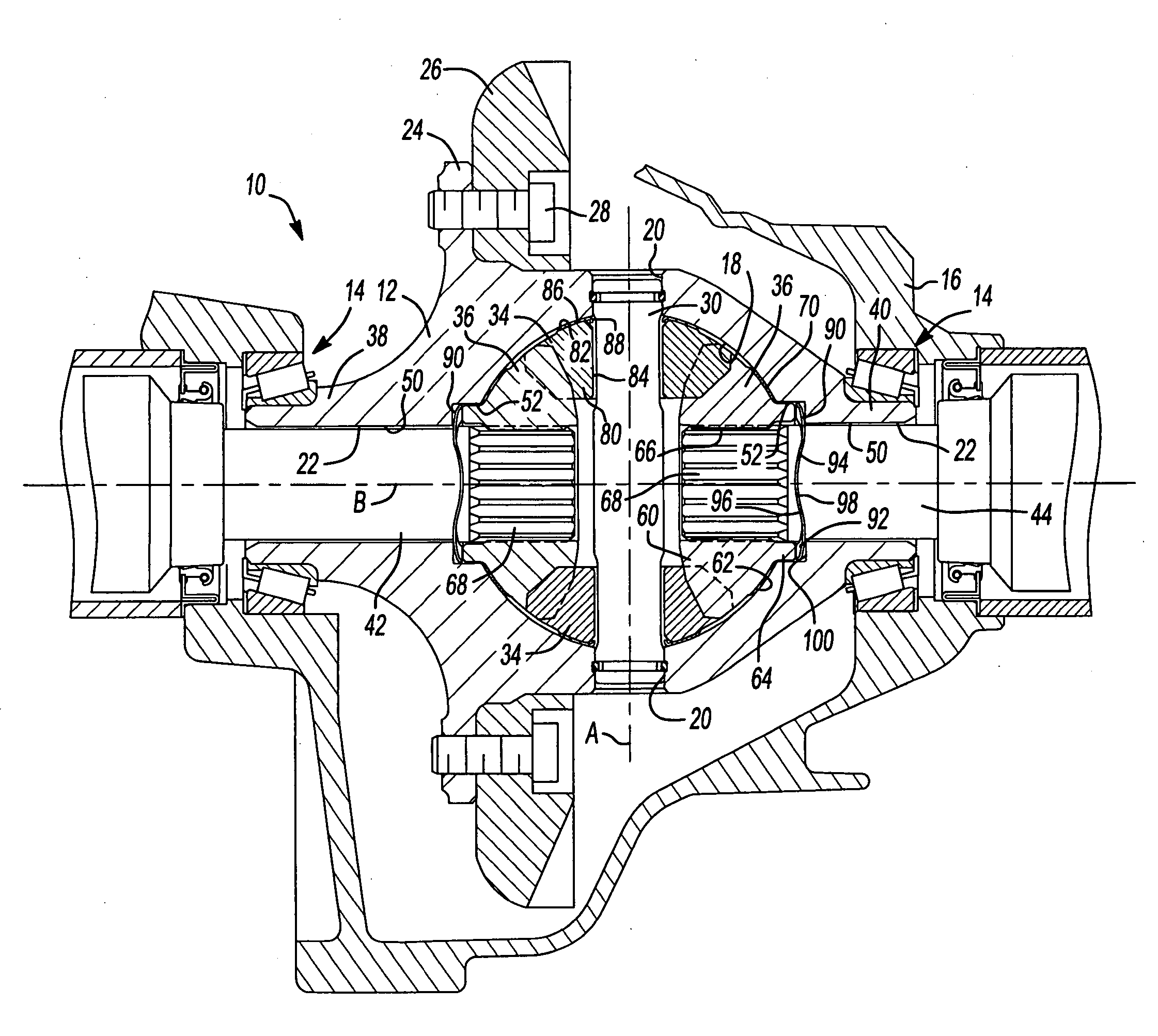

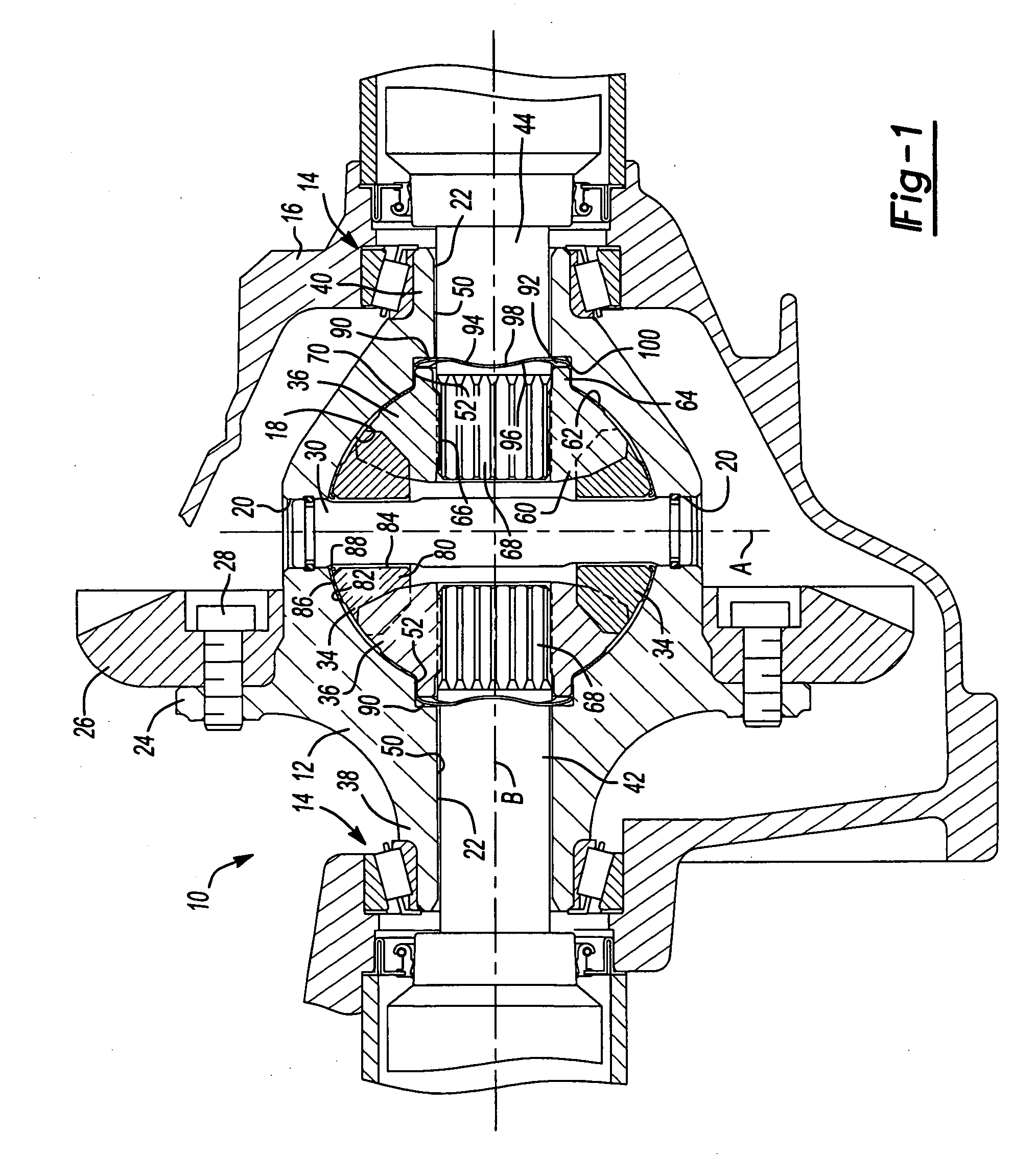

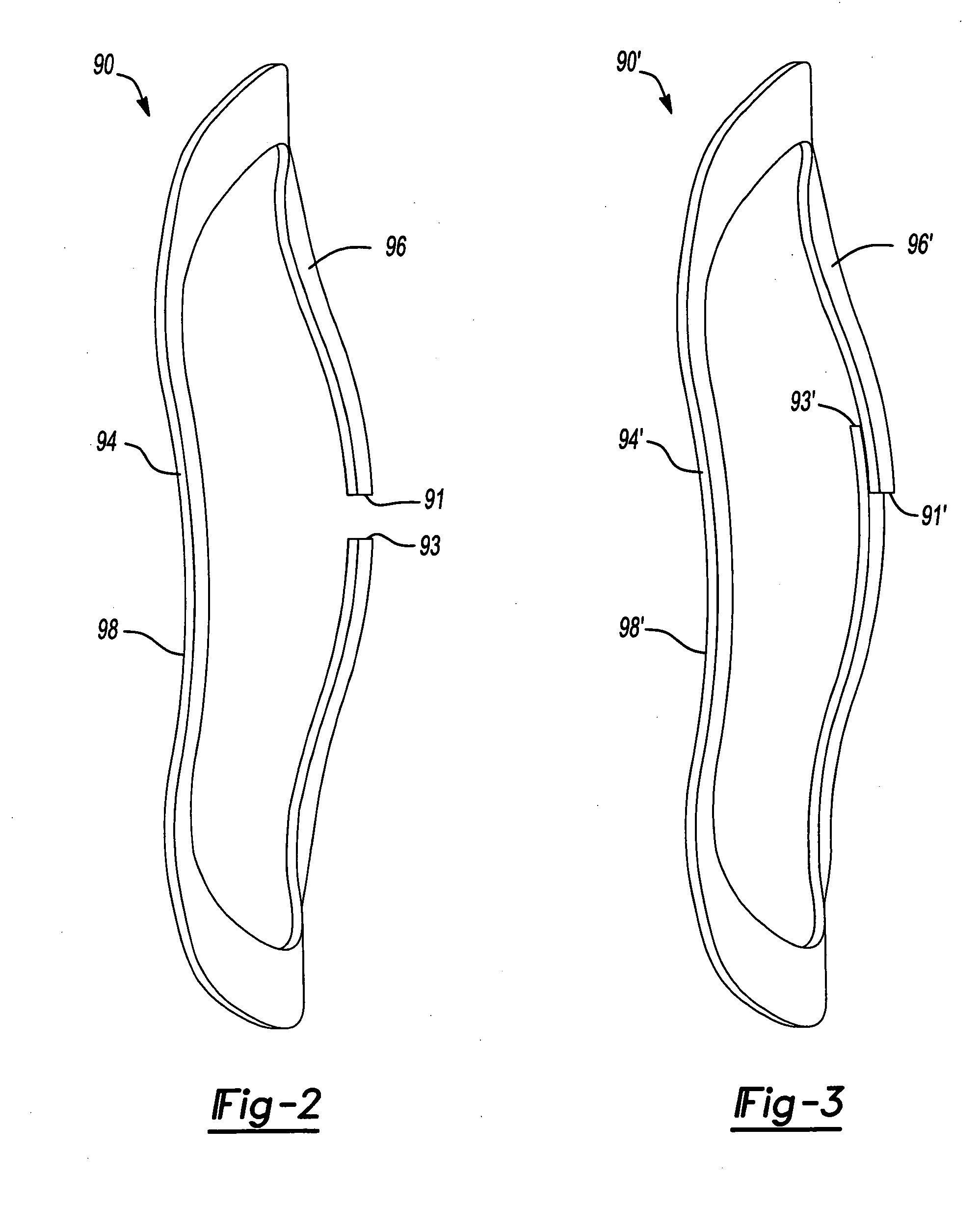

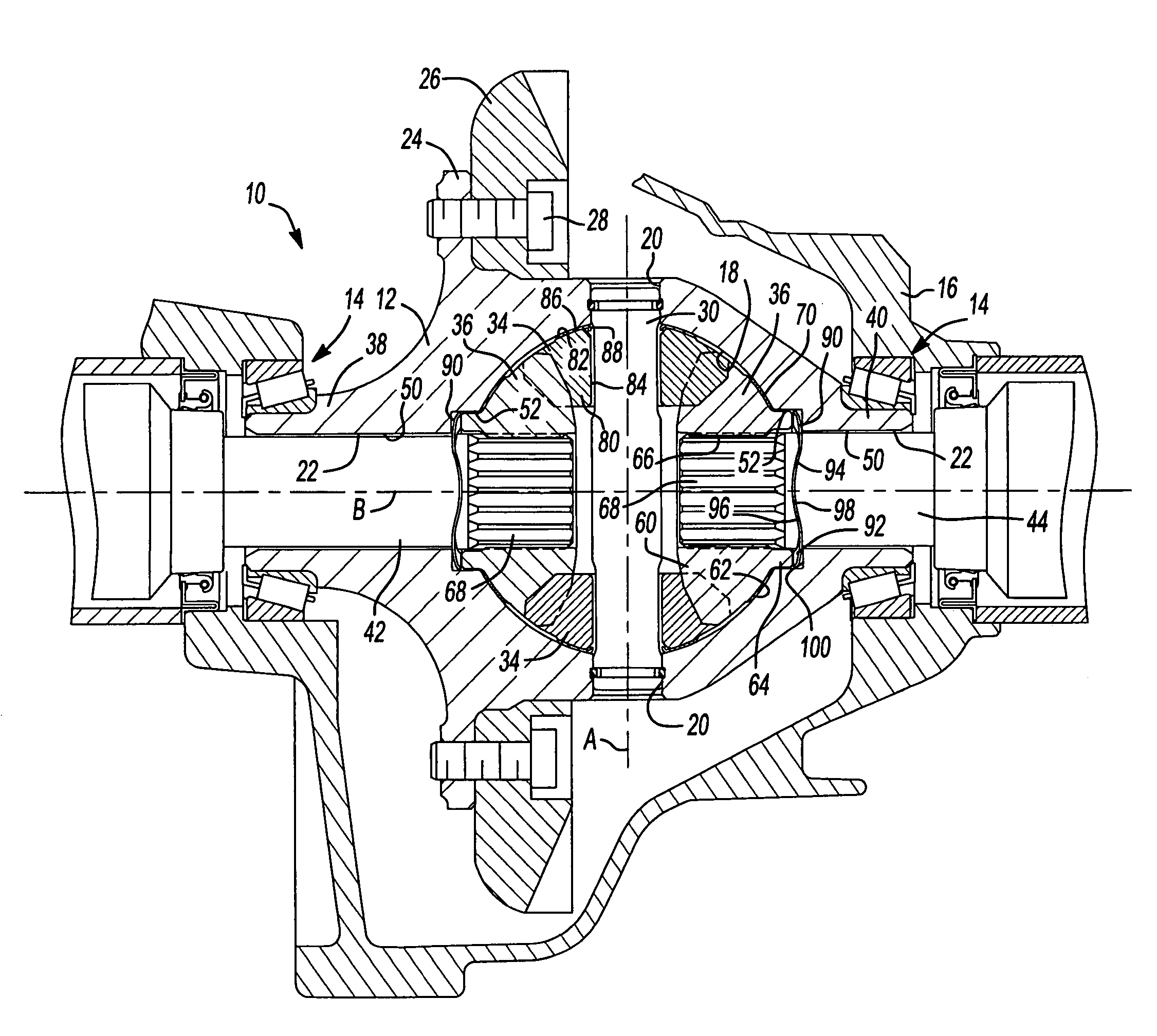

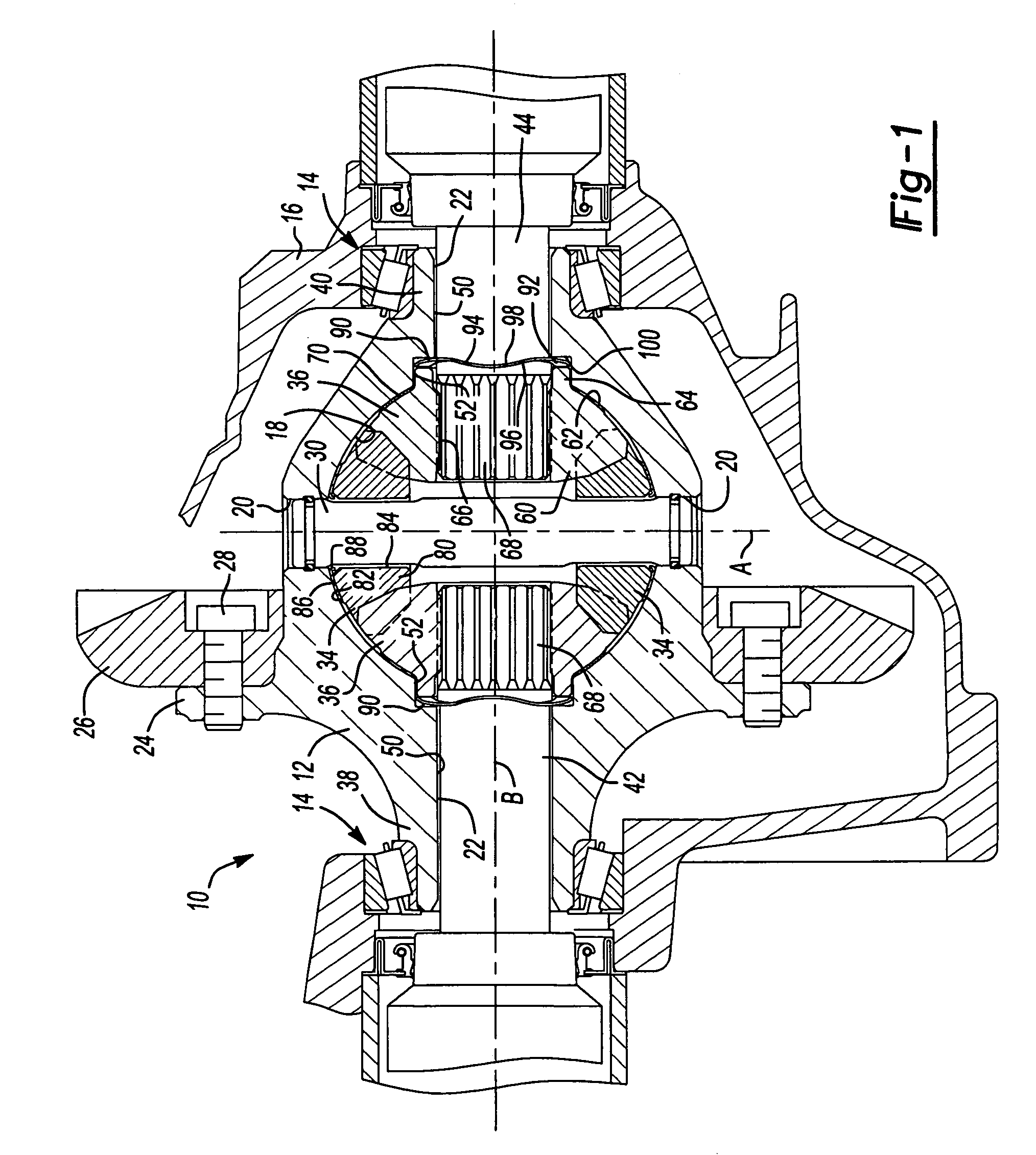

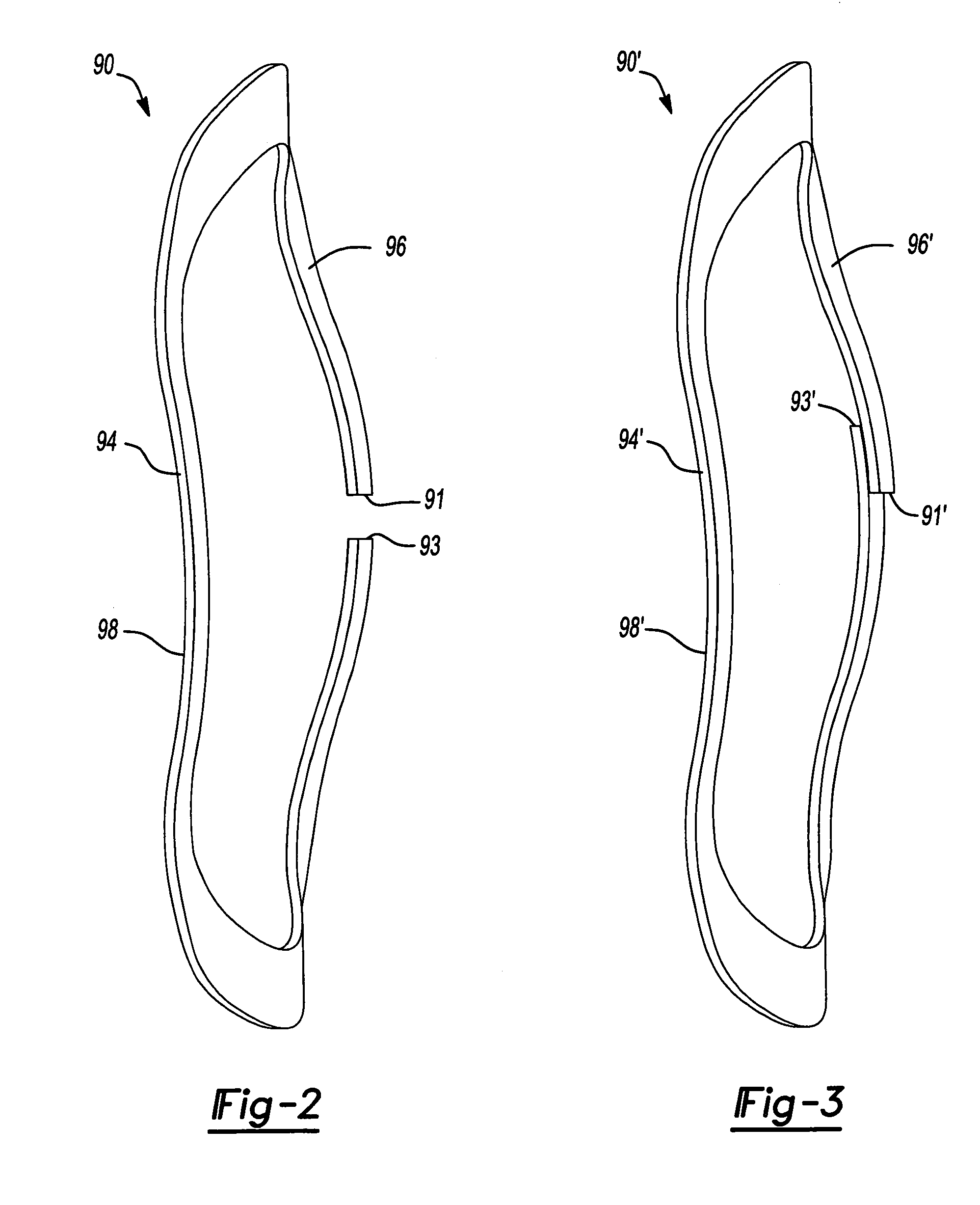

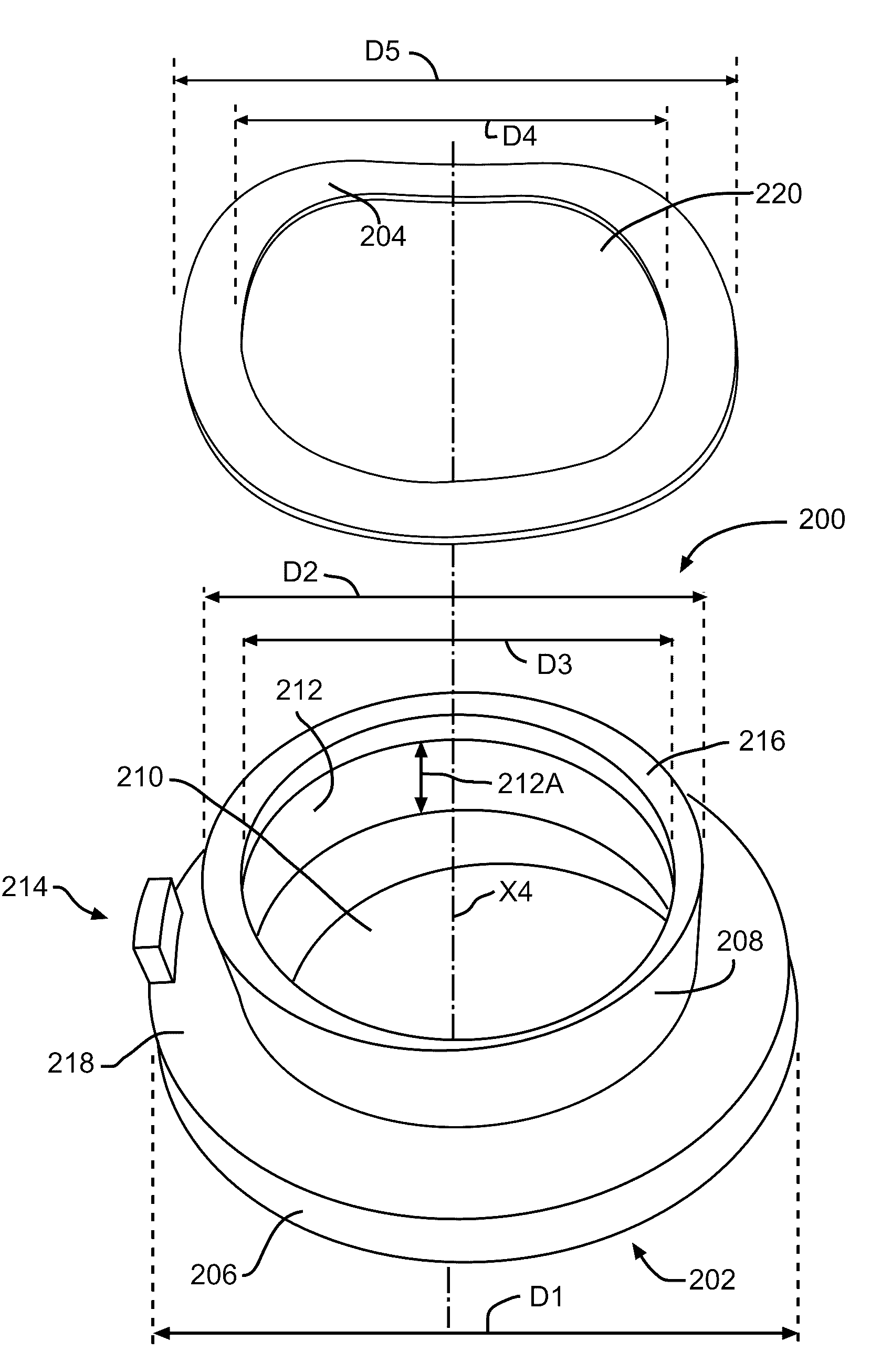

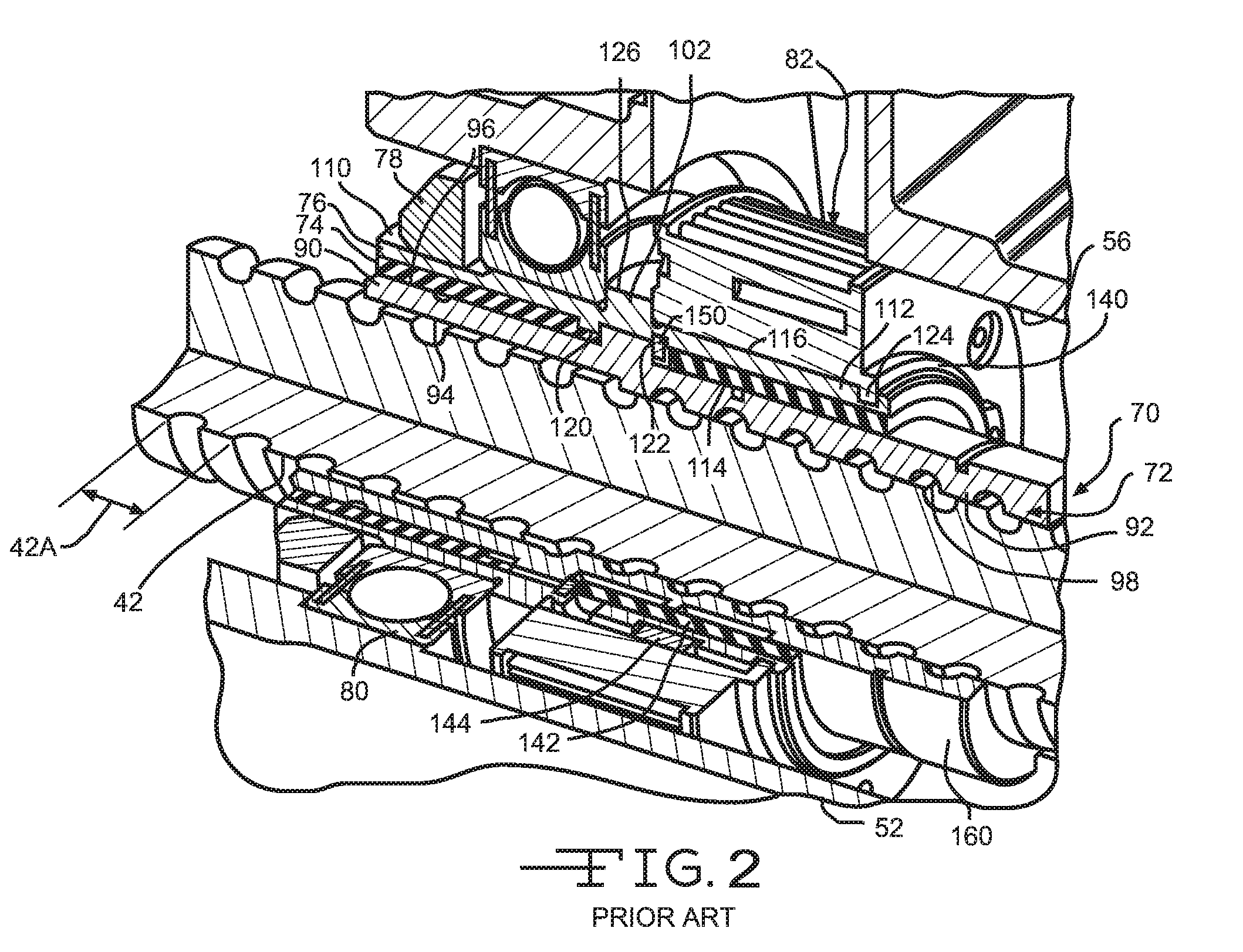

"Zero" lash spherical differential assembly using spring washers

ActiveUS20060240934A1Improve structural durabilityEasy to manufactureDifferential gearingsGearing detailsEngineeringPinion

A differential assembly includes a differential housing including a substantially spherically shaped chamber. A pair of spherically shaped side gears are rotatably positioned in the chamber in driving communication with a pair of spherically shaped pinion gears. A pair of springs are positioned in engagement with the end faces of the side gears to minimize gear lash between the side gears and the pinion gears.

Owner:AMERICAN AXLE & MFG

"Zero" lash spherical differential assembly using spring washers

ActiveUS7278948B2Improve structural durabilityEasy to manufactureDifferential gearingsGearing detailsPinionMechanical engineering

A differential assembly includes a differential housing including a substantially spherically shaped chamber. A pair of spherically shaped side gears are rotatably positioned in the chamber in driving communication with a pair of spherically shaped pinion gears. A pair of springs are positioned in engagement with the end faces of the side gears to minimize gear lash between the side gears and the pinion gears.

Owner:AMERICAN AXLE & MFG

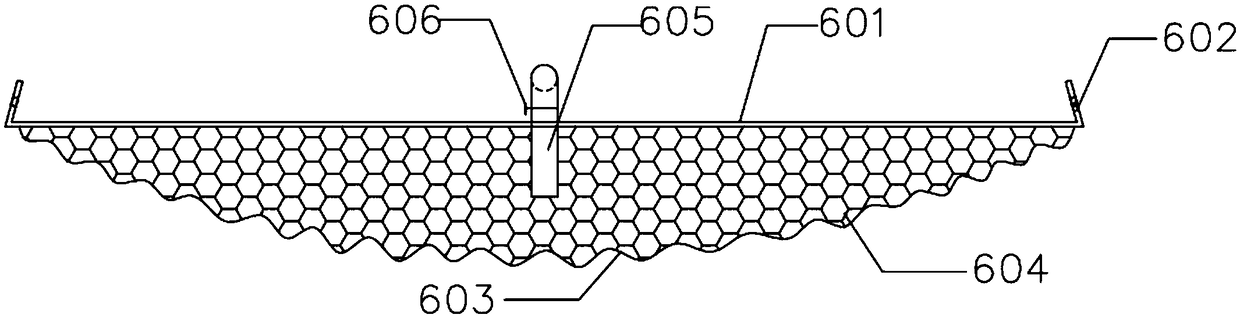

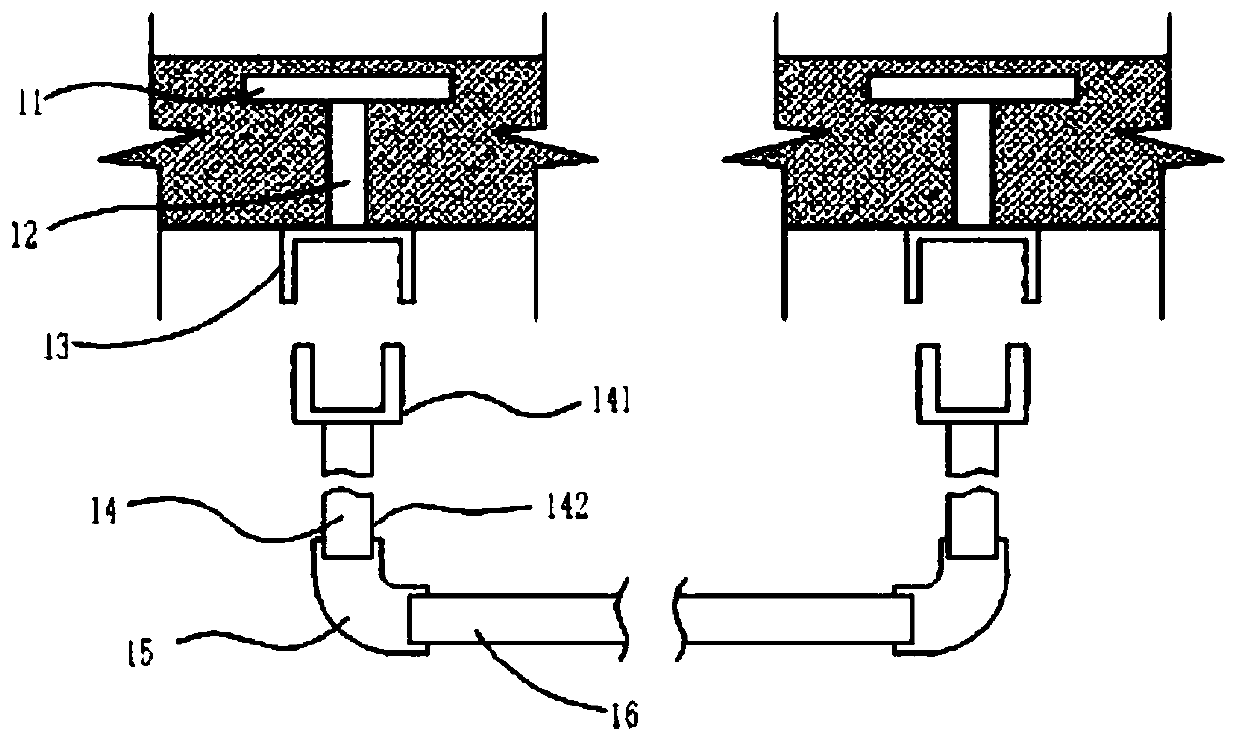

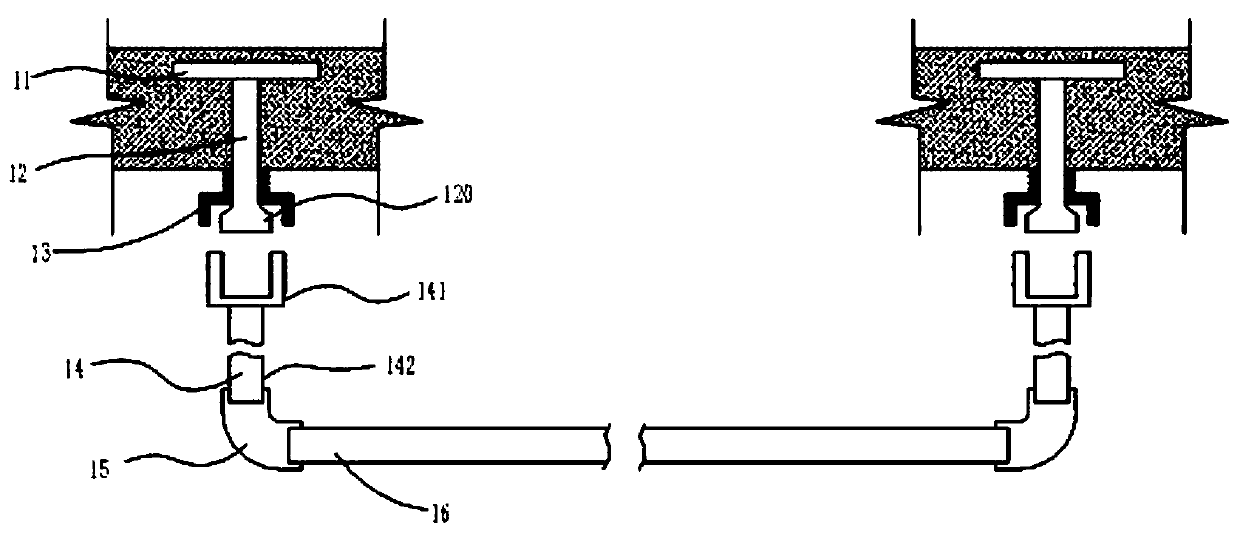

Foundation pit breast board supporting and sealing structure and construction method thereof

The invention discloses a pit breast board supporting and sealing structure and a construction method thereof. The pit breast board supporting and sealing structure comprises drilling injection piles,breast board anchoring and positioning devices and a breast board; the breast board anchoring and positioning devices are vertically fixed on a rebar cage at intervals; each breast board anchoring and positioning device comprise support brace rods, a large arc brace rod and a small arc brace rod; U-shaped grooves are fixed on two sides of the support brace rods; a steel plate sealing belt is arranged in each U-shaped groove; the breast board is provided with a body; two ends of the body are bent upwards and form bending edges; and the bending edges of the breast board are separately connectedto the steel plate sealing belts in the U-shaped grooves on the injection piles on the two sides and form a breast sealing edge jointly with the injection piles on the two sides. The earth-among-pilebreast board disclosed by the invention is convenient to assemble and disassemble and is easy to operate; the breast board can baffle soil and can also baffle water and prevent permeation; foundationpit supporting time can be shortened; on-site construction speed can be enhanced; besides, the tool-type breast board can be used repeatedly, so that cost is reduced; and the construction cost is lowered.

Owner:CHINA FIRST METALLURGICAL GROUP

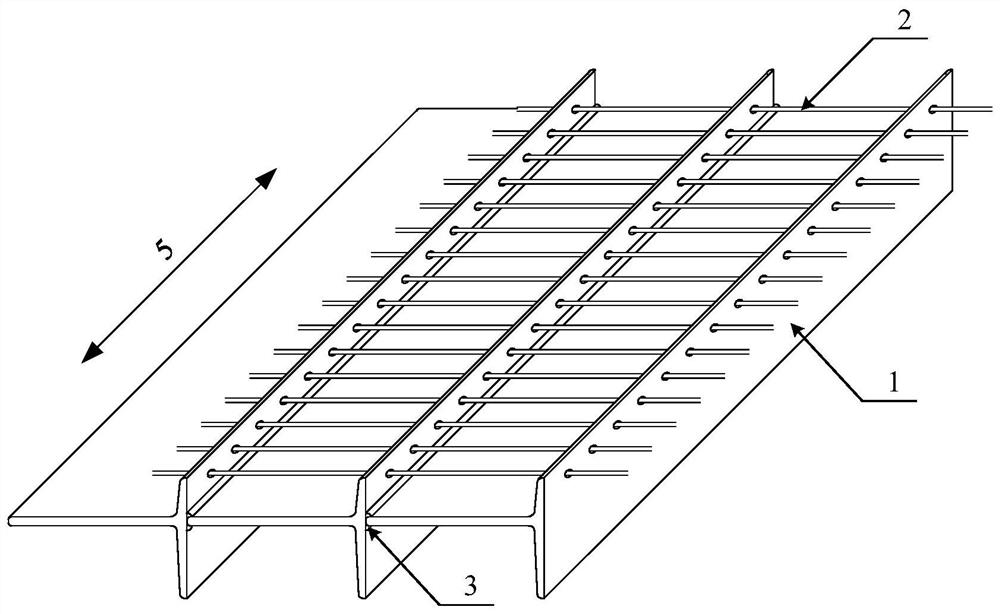

Tough combined bridge deck slab composed of T-shaped steel

ActiveCN112195778APrevent rustImprove toughnessSolid waste managementBridge structural detailsFillet weldBridge deck

The invention discloses a tough combined bridge deck slab system composed of T-shaped steel. The tough combined bridge deck slab system comprises hot-rolled T-shaped steel, transverse steel bars and ultrahigh-toughness concrete. The T-shaped steel is transversely and continuously placed side by side along a bridge deck, and adjacent steel is welded through two fillet welds to form a bridge deck steel framework. The lower side flange of the T-shaped steel is long and plays a role in reinforcing the outer side of the slab surface; the upper side flange of the hot-rolled T-shaped steel is short and is provided with a row of circular holes, and the transverse steel bars penetrate through the flanges of the T-shaped steel through the circular holes. The ultrahigh-toughness concrete is poured onthe bridge deck steel framework to play a role in protecting the bridge deck steel framework. In the combined bridge deck slab system provided by the invention, the ultra-high toughness concrete canensure that tiny cracks of 100 microns or below are not generated or only tiny cracks of 100 microns or below are generated, and the toughness and durability of the structure are improved; the T-shaped steel and the transverse steel bars are combined to replace the anti-shearing and anti-pulling effects of studs, so that the out-of-plane stability of the bridge deck slab is improved, the materialcost and the construction complexity are remarkably reduced, and the fatigue performance is excellent.

Owner:ZHEJIANG UNIV

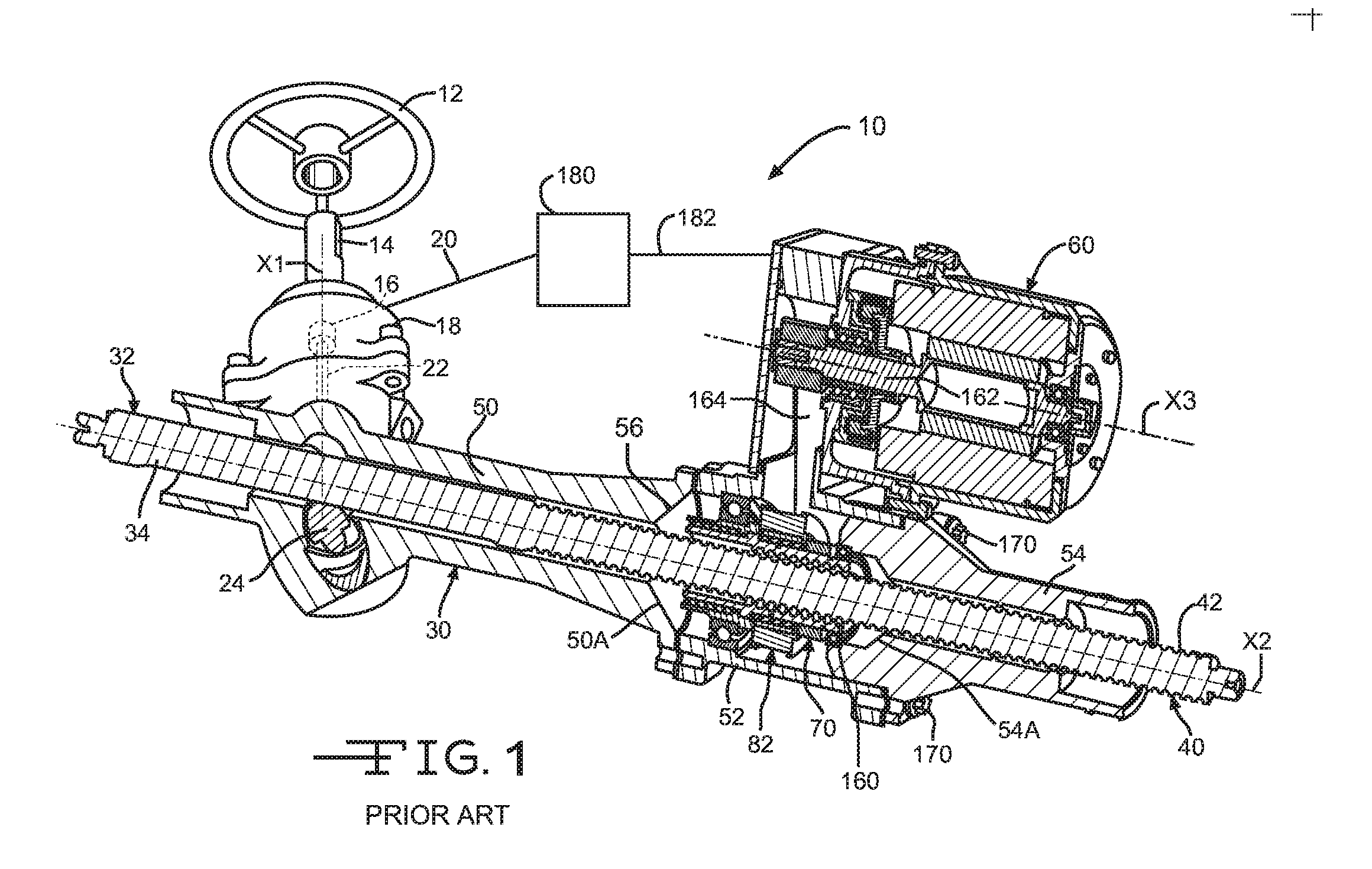

Anti-Lash Assembly For Vehicle Power Steering

A vehicle power steering assembly comprises a steering member having a screw portion. The screw portion has an external screw thread convolution with a first lead spacing. A ball nut is operatively connected to the screw portion. A bushing is operatively connected to the screw portion. The bushing has a bushing screw thread convolution with a second lead spacing. The second lead spacing is different than the first lead spacing. The bushing biases the ball nut against the screw portion.

Owner:TRW AUTOMOTIVE US LLC

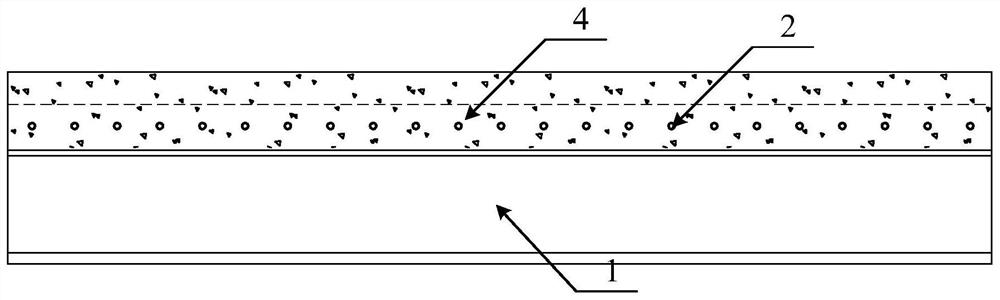

Stud-free tough combined bridge deck slab system

ActiveCN112227200APrevent rustImprove toughnessBridge structural detailsBridge materialsFillet weldArchitectural engineering

The invention discloses a stud-free tough combined bridge deck slab system. The stud-free tough combined bridge deck slab system comprises L-shaped hemming profile steel, longitudinal reinforcing steel bars and ultrahigh-toughness concrete. The L-shaped hemming section steel is continuously arranged side by side in the longitudinal direction of a bridge deck, and adjacent section steel is welded through two fillet welds to form a bridge deck steel framework. A row of circular holes are formed in each L-shaped hemming section steel flange plate, and the longitudinal reinforcing steel bars penetrate through the L-shaped hemming section steel flange plates through the circular holes. And the ultrahigh-toughness concrete is poured on the bridge deck steel skeleton to play a role in protectingthe bridge deck steel skeleton. In the combined bridge deck slab system provided by the invention, the ultra-high toughness concrete can ensure that tiny cracks of below 100 microns are not generatedor only generated under the action of various loads, and the toughness and durability of the structure are improved; the structural mode of combining the L-shaped hemming profile steel and the longitudinal reinforcing steel bars achieves the effective anti-shearing and anti-pulling effects, the effects of studs and transverse reinforcing steel bars are replaced, so that the material cost and the construction complexity are greatly reduced, and the fatigue performance is excellent.

Owner:ZHEJIANG UNIV

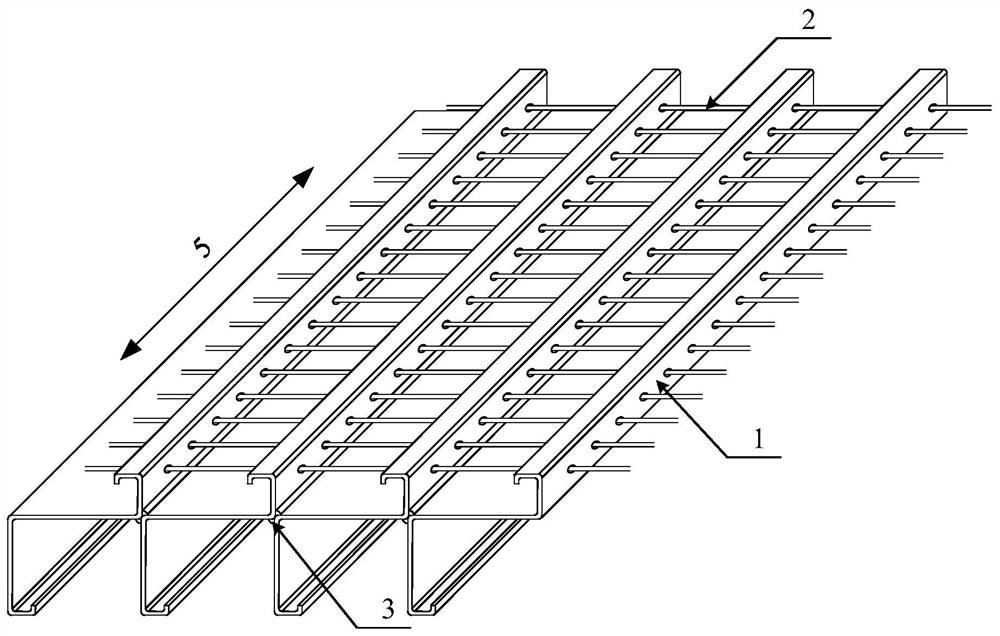

Tough combined bridge deck composed of cold-bent Z-shaped steel

ActiveCN112227199AImprove toughnessIncreased durabilityBridge structural detailsBridge materialsFillet weldBridge deck

The invention discloses a tough combined bridge deck composed of cold-bent Z-shaped steel. The tough combined bridge deck comprises cold-bent curled Z-shaped steel, transverse reinforcing steel bars and ultrahigh-toughness concrete. And the cold-bent Z-shaped steel is transversely and continuously placed along the bridge deck and forms bridge deck steel framework through fillet weld welding. The lower side flange of the cold-bent Z-shaped steel is long and plays a role in reinforcing the outer side of the plate surface; the upper side flange is short and is provided with a row of circular holes, and the transverse reinforcing steel bars penetrate through the cold-bent Z-shaped steel flanges through the circular holes. And the ultrahigh-toughness concrete is poured on the bridge deck steelskeleton to play a role in protecting the bridge deck steel skeleton. In the combined bridge deck slab system provided by the invention, the ultra-high toughness concrete can ensure that tiny cracks of below 100 microns are not generated or only generated, and the toughness and durability of the structure are improved; the construction mode of combining the cold-bent Z-shaped steel and the transverse reinforcing steel bars replaces the anti-shearing and anti-pulling effects of studs, meanwhile, the out-of-plane stability of the bridge deck slab is improved, the material cost and the construction complexity are remarkably reduced, and the fatigue performance is excellent.

Owner:ZHEJIANG UNIV

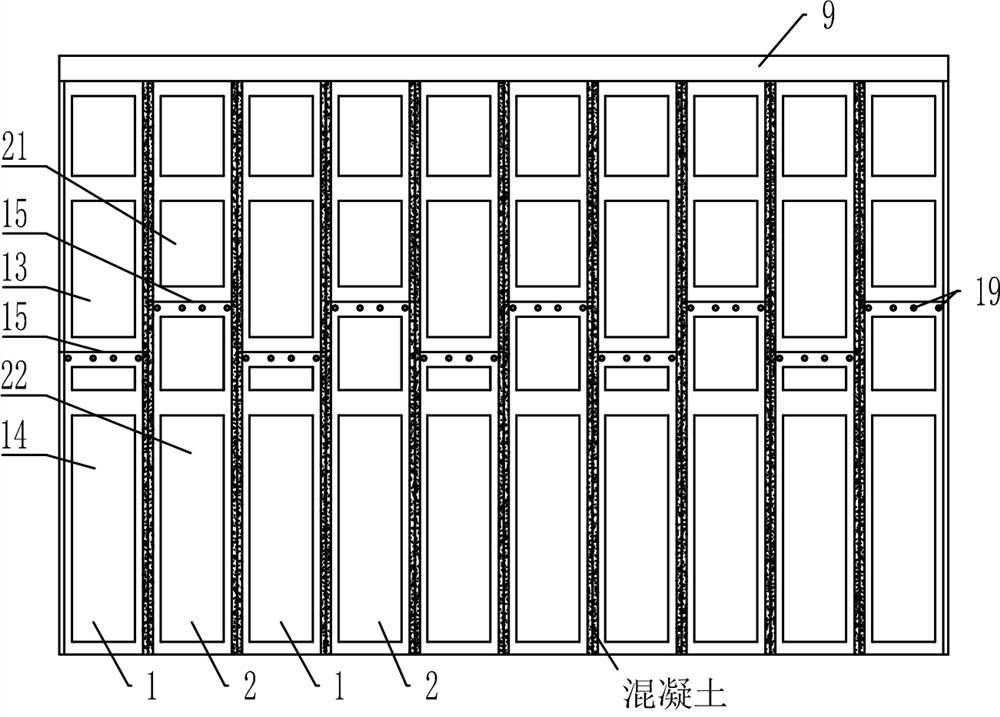

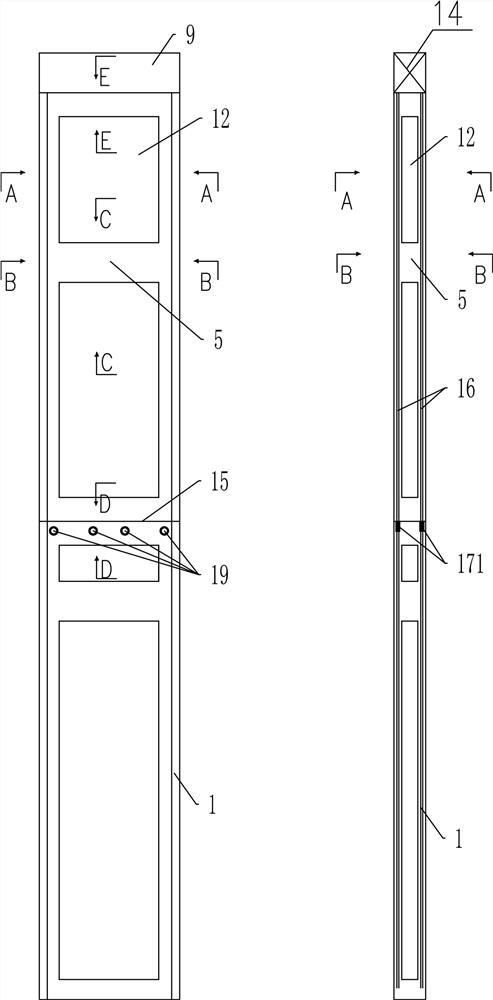

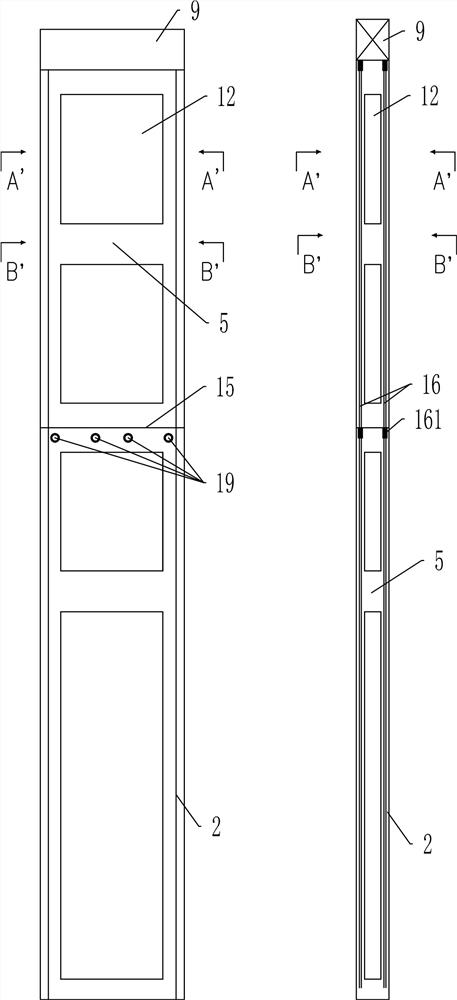

Fabricated shear wall lateral steel bar connecting device and application method thereof

PendingCN112761310AImprove hoisting efficiencyReduce conflictWallsBuilding reinforcementsEngineeringRebar

The invention discloses a fabricated shear wall lateral steel bar connecting device and an application method thereof. The fabricated shear wall lateral steel bar connecting device comprises H-shaped steel, wherein U-shaped grooves are formed in the two ends of a side plate of the H-shaped steel respectively, horizontal reserved steel bars penetrate into the U-shaped grooves from prefabricated shear wall bodies on the two sides separately and are in threaded connection to high-strength nuts on the inner side wall of the H-shaped steel, steel rod reserved holes are formed in notches of the U-shaped grooves and in the side plate of the H-shaped steel, the steel rod is inserted into the steel rod reserved holes in a matched manner, and longitudinal reserved steel bars of a lower wall body penetrate through included angles formed by the two ends of the outer side wall of the H-shaped steel and the horizontal reserved steel bars and are fixedly connected to the horizontal reserved steel bars. Prefabricated shear walls are hoisted from the upper portion of the longitudinal reserved steel bars from top to bottom, the H-shaped steel, the horizontal reserved steel bars and the longitudinal reserved steel bars are assembled and connected to form a whole after the shear walls are hoisted in place, the shear resistance and the integrity of the wall bodies are enhanced, stirrups at connecting positions are replaced with the H-shaped steel, binding with the stirrups is reduced, the hoisting efficiency is improved, the construction difficulty is reduced, and the device has the advantages of simple structure, strong shear resistance, good integrity, practicability and high efficiency.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Thermally-induced fusing steel ball lock pressing and releasing mechanism

ActiveCN113120260ASimple structureLight in massCosmonautic vehiclesCosmonautic component separationSet screwEngineering

The invention discloses a thermally-induced fusing steel ball lock pressing and releasing mechanism which comprises a base, a hoop, a restraining rope, an unlocking spring, a lock column, a heater, a pressing sleeve, a pressing cap, a pressing rod, a locking nut, a force bearing bowl, a sliding block, a pin pulling spring, a steel ball and a set screw. Locking and releasing of the pressing and releasing mechanism are achieved through the relative position relation among the locking column, the clamping hoop and the pressing rod, an unlocking spring is installed between the locking column and the clamping hoop, and a restraining rope is bound between the locking column and the clamping hoop. The restraint rope restrains the position between the lock column and the hoop, so that the pressing and releasing mechanism is in a locked state, and the spring is in a compressed state; a heater is installed on the restraint rope, the heater is powered on, the restraint rope is fused, the unlocking spring pushes the hoop to move by a certain distance, and the pressing and releasing mechanism is changed into an unlocking and releasing state from a locking state. The pressing and releasing mechanism has the characteristics of simple structure, light weight, low impact, low cost, wide temperature adaptability, high locking and unlocking reliability and the like.

Owner:SHANGHAI AEROSPACE SYST ENG INST

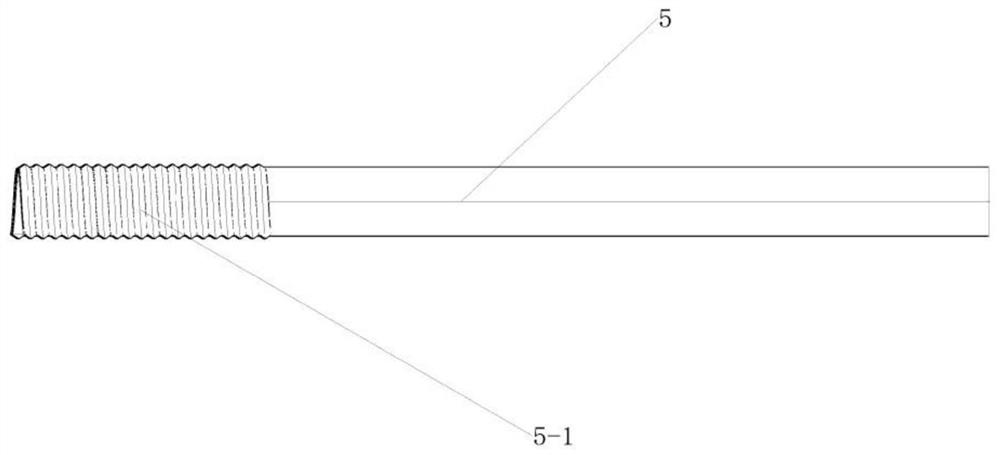

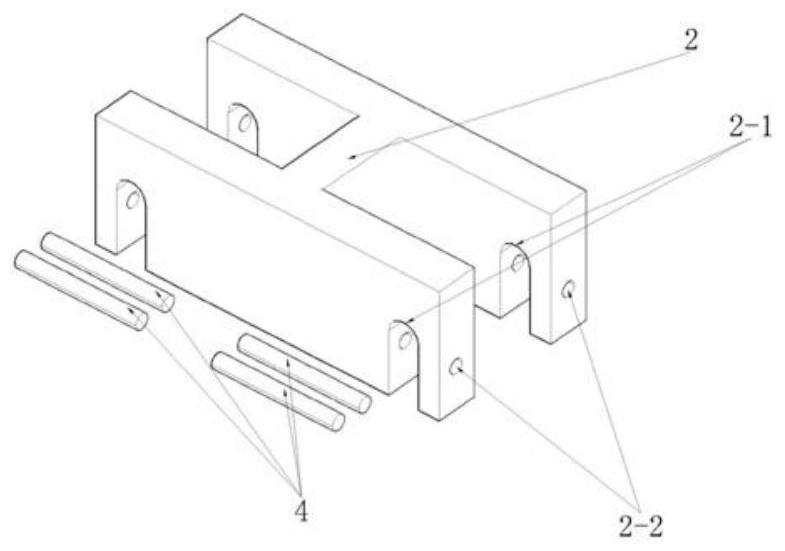

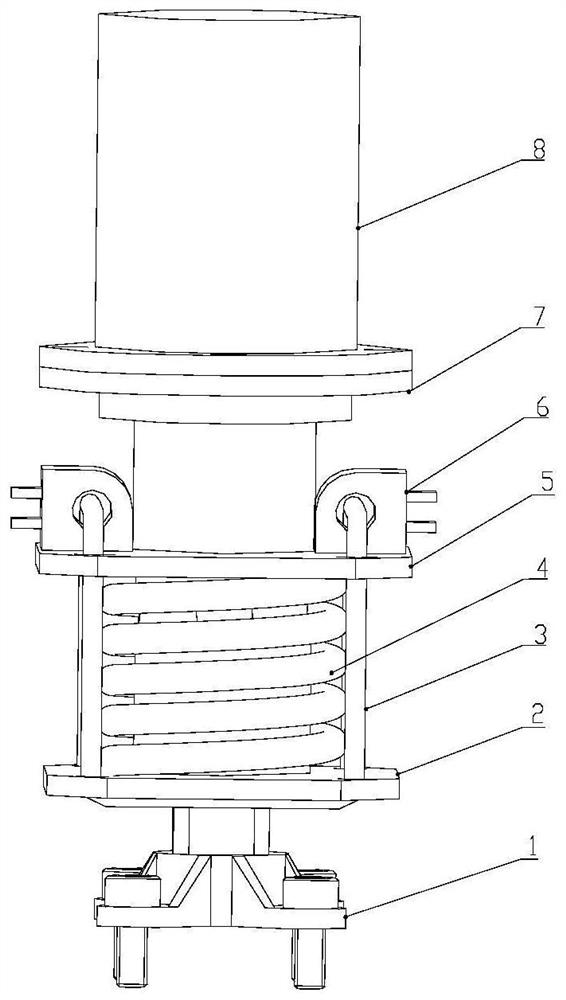

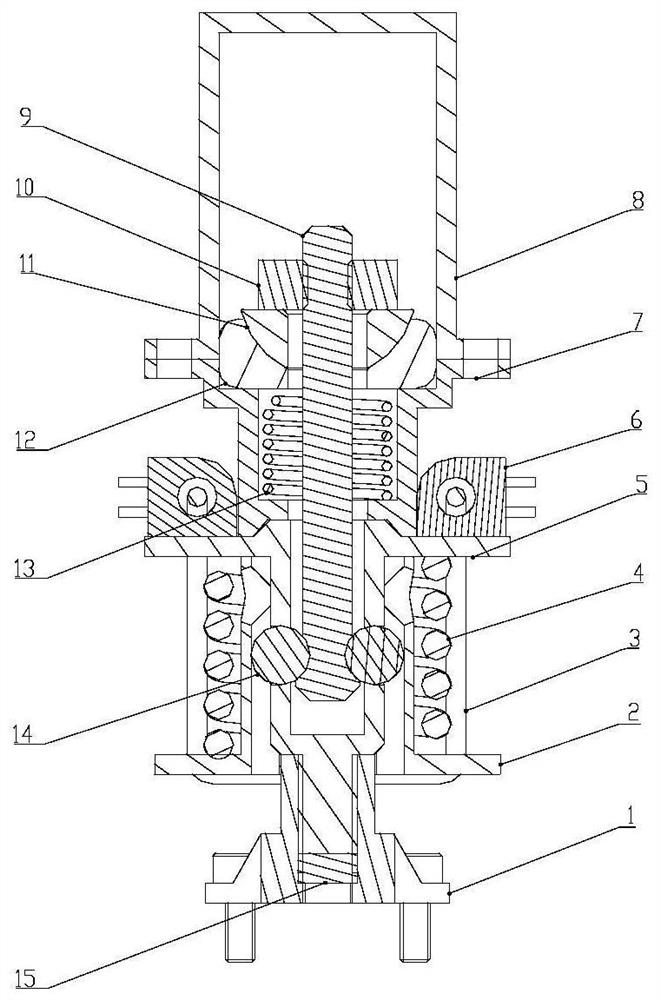

Thermally-induced fusing steel ball lock separating mechanism

PendingCN113120259ASimple structureLight in massCosmonautic vehiclesCosmonautic component separationPhysicsEngineering

The invention discloses a thermally-induced fusing steel ball lock separating mechanism. The separating mechanism comprises a shell (1), an unlocking column (2), an unlocking spring (3), a restraining rope (4), a heater (5), a steel ball (6), a lock cap (7), a check ring (8), a limiting ring (9) and a limiting spring (10). Locking and releasing of the lock cap are achieved through the relative position relation among the shell, the unlocking column and the lock cap, an unlocking spring is installed between the unlocking column and the shell, and a restraining rope is bound between the unlocking column and the shell. The restraint rope restrains the position between the unlocking column and the shell, so that the separation mechanism is in a locked state, and the spring is in a compressed state; a heater is installed on the restraint rope, the heater is powered on, the restraint rope is fused, the unlocking spring pushes the unlocking column to move by a certain distance, and the separation mechanism is changed into an unlocking and releasing state from a locking state. The separation mechanism has the characteristics of simple structure, light weight, low impact, low cost, wide temperature adaptability, high locking and unlocking reliability and the like.

Owner:SHANGHAI AEROSPACE SYST ENG INST

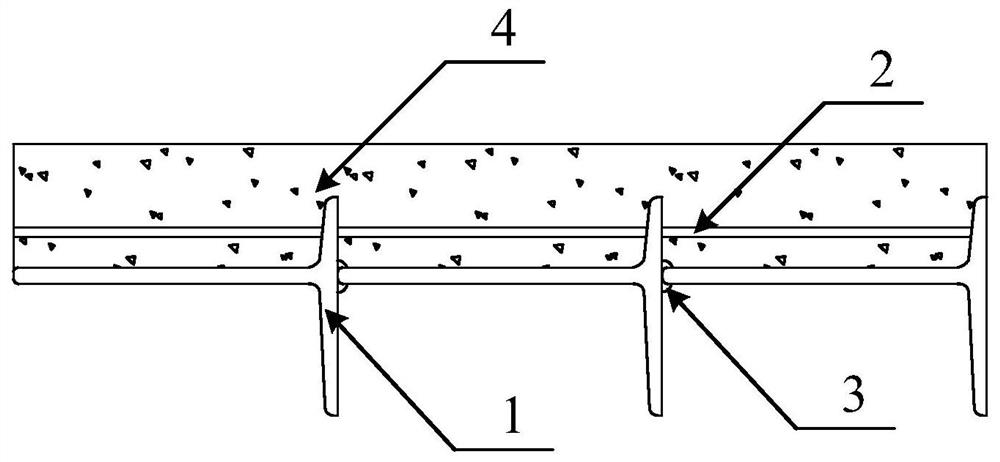

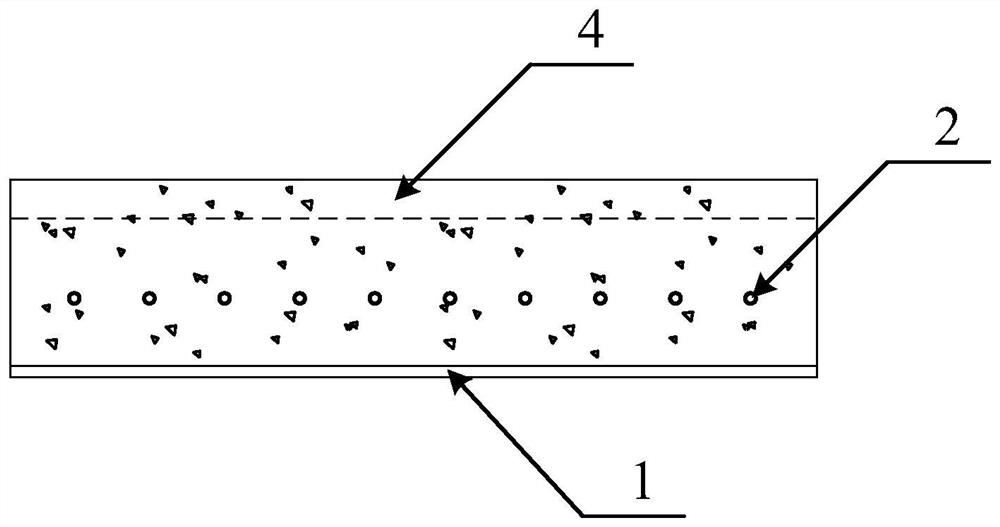

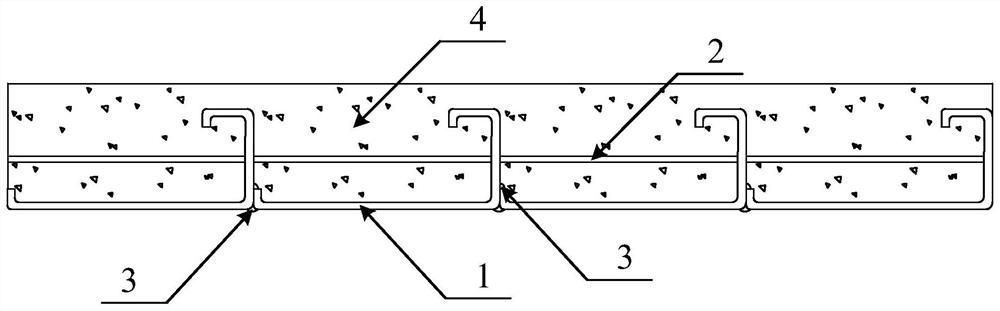

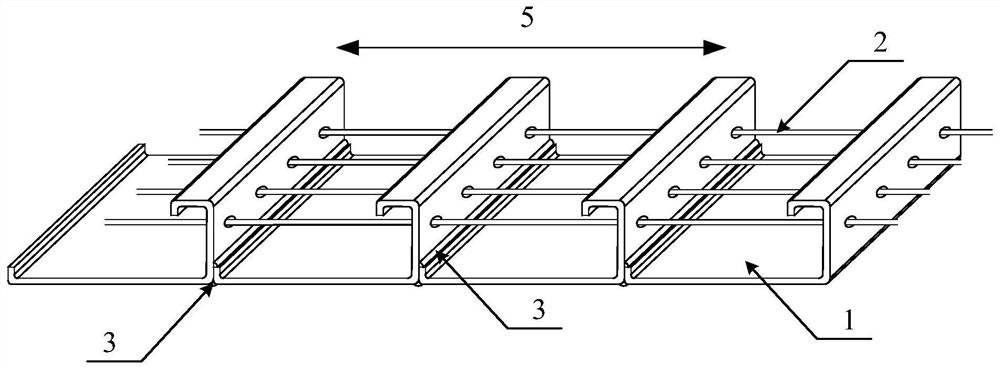

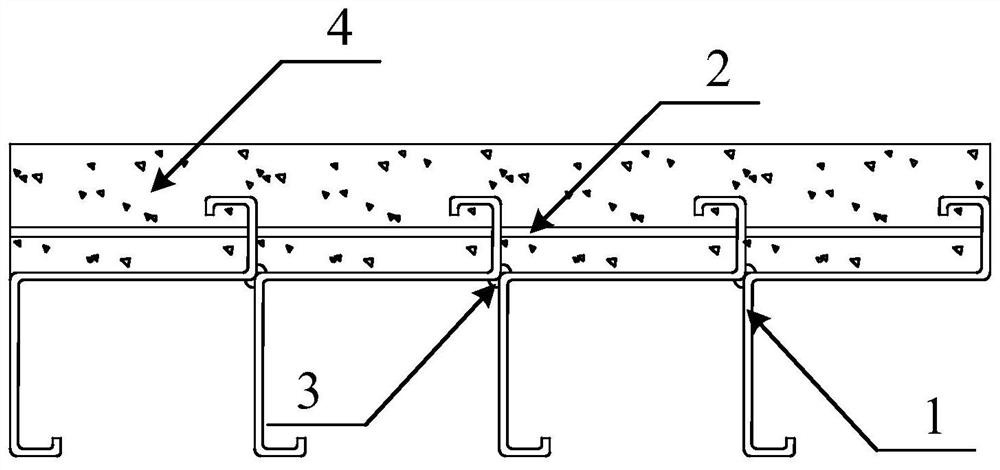

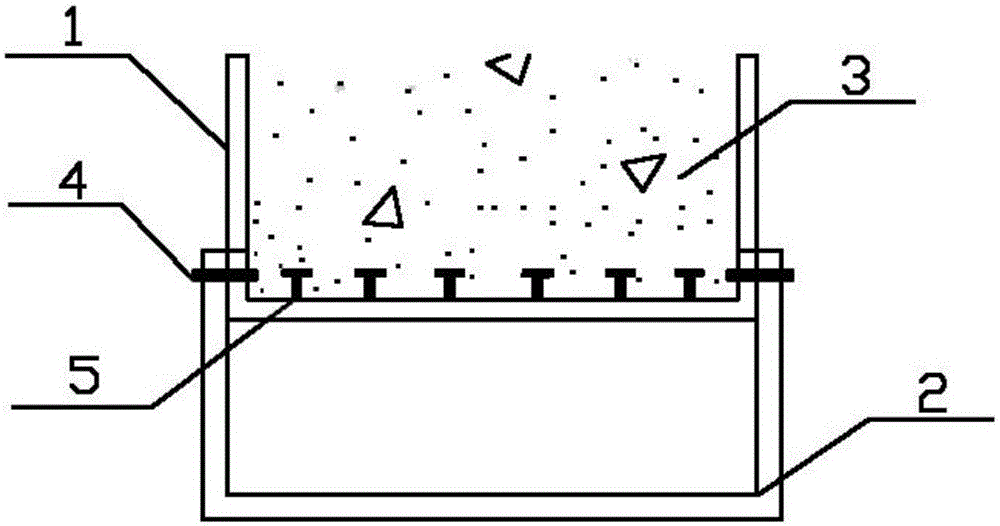

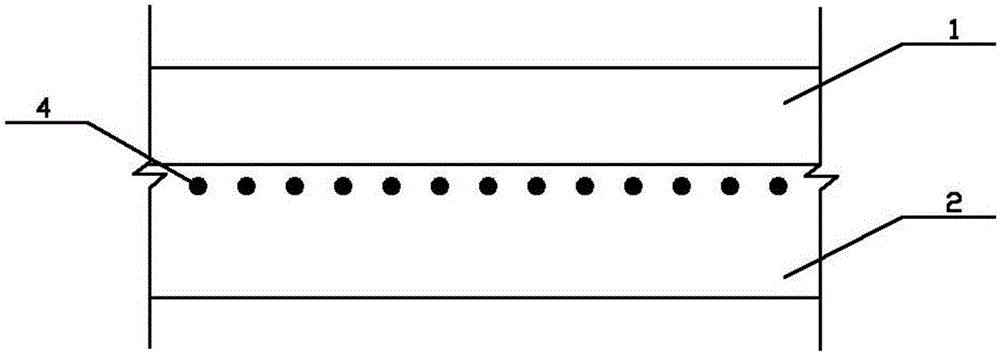

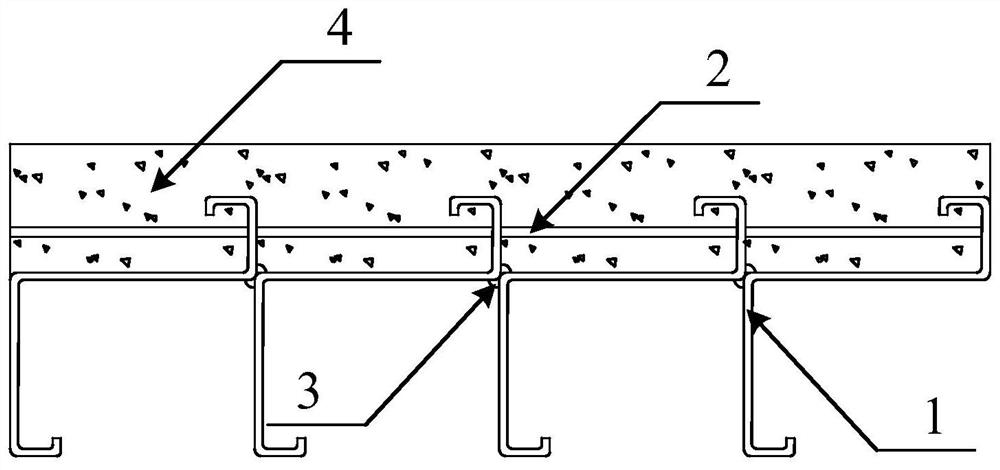

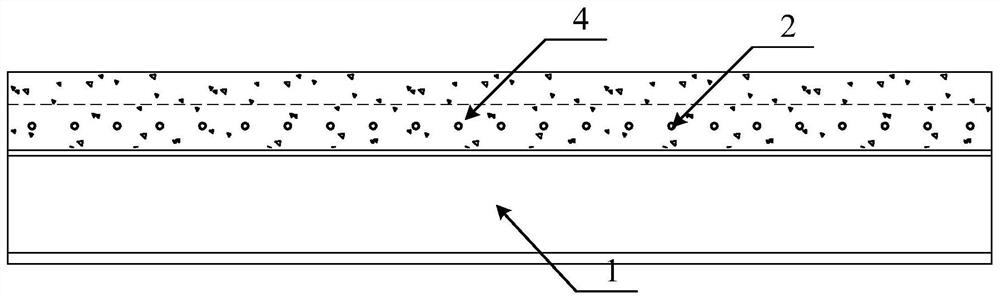

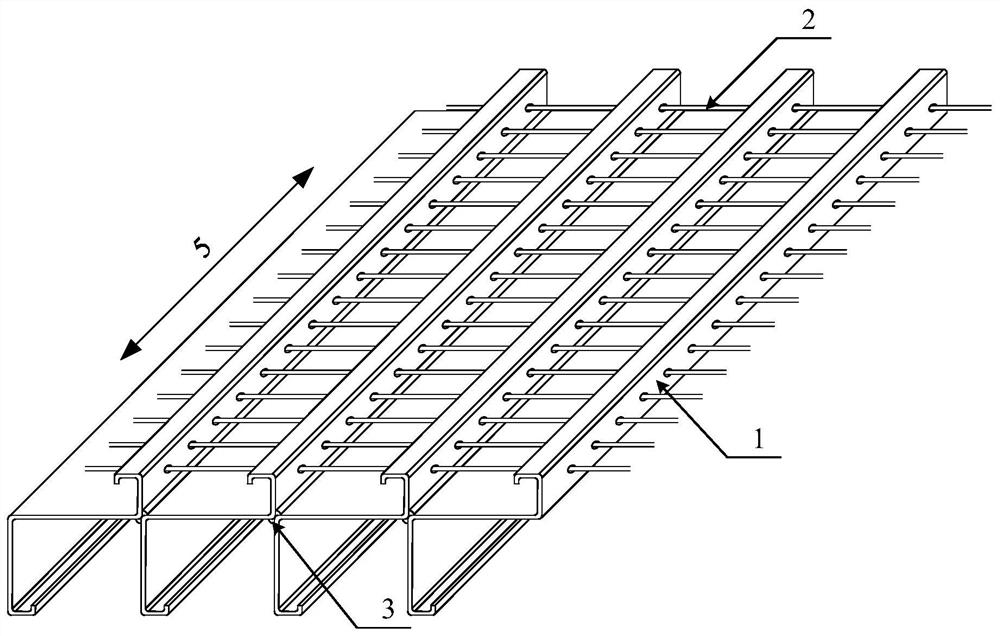

Duplex channel steel and recycled concrete combination beam

InactiveCN105155774AStrong bending abilityReduce weightSolid waste managementLoad-supporting elementsRebarConstruction aggregate

Owner:HOHAI UNIV

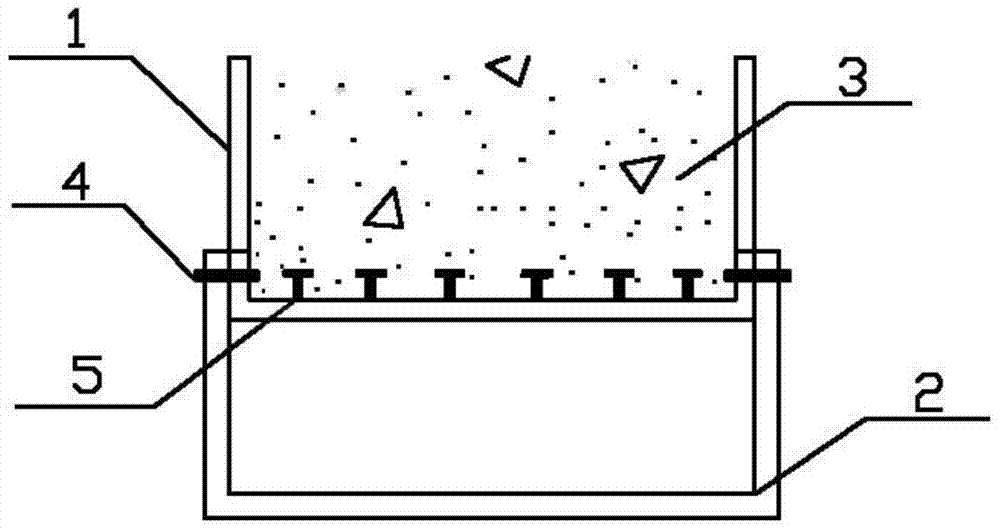

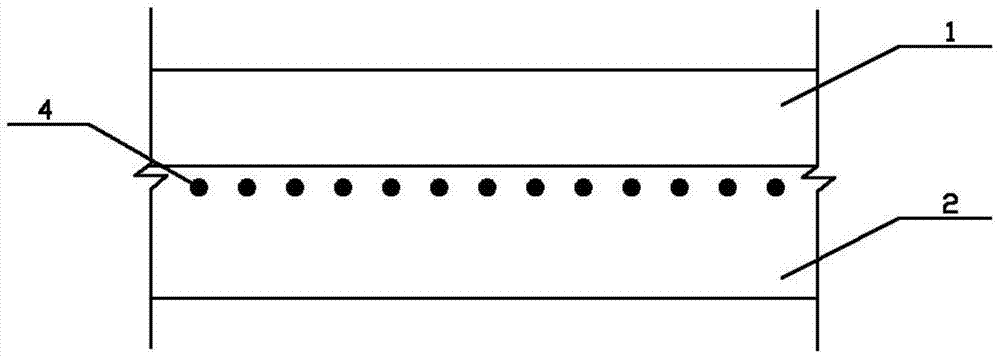

Assembly type laminated slab anchoring structure convenient to construct and connecting mode thereof

The invention discloses an assembly type laminated slab anchoring structure convenient to construct and a connecting mode thereof. The anchoring structure comprises a first anchoring part used for being in anchoring connection with the outside and a second anchoring part used for being in anchoring connection between assembly type laminated slabs. The connecting mode comprises the steps that afterthe first anchoring part is prefabricated, then when the assembly type laminated slabs are prepared, the first anchoring part and the second anchoring part are locally pre-buried in concrete of the prefabricated layer, and finally in later laminated slab assembly construction, the first anchoring part and the second anchoring part are completely assembled, and then concrete preparation of a cast-in-place layer is carried out. According to the assembly type laminated slab anchoring structure convenient to construct and the connecting mode thereof, the adopted first anchoring part can effectively ensure fixation of the assembly type laminated slabs when the assembly type laminated slabs are mounted; and the adopted anchoring structure has better stability, binding of field steel bars can beeffectively reduced in actual field construction, and construction is more convenient.

Owner:UNIV OF JINAN

Double-layer channel-recycled concrete composite beam

InactiveCN105155774BImprove bending abilityReduce lashingSolid waste managementLoad-supporting elementsRebarMaterials science

Owner:HOHAI UNIV

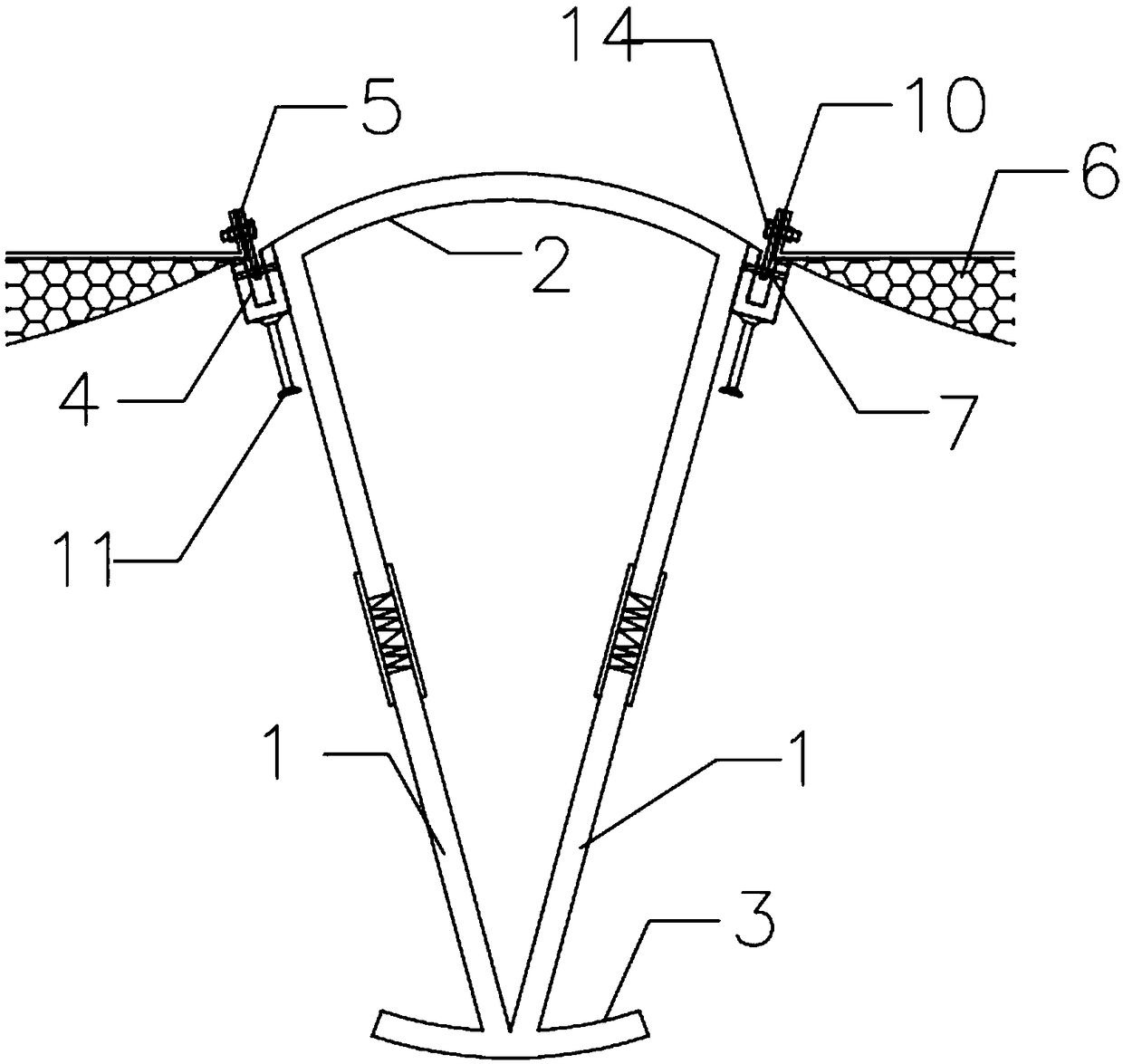

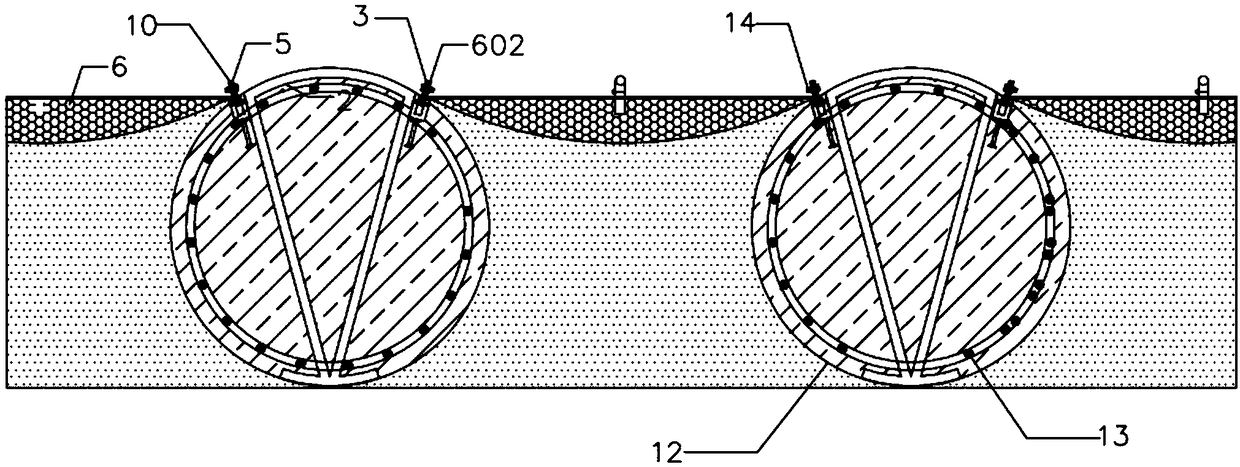

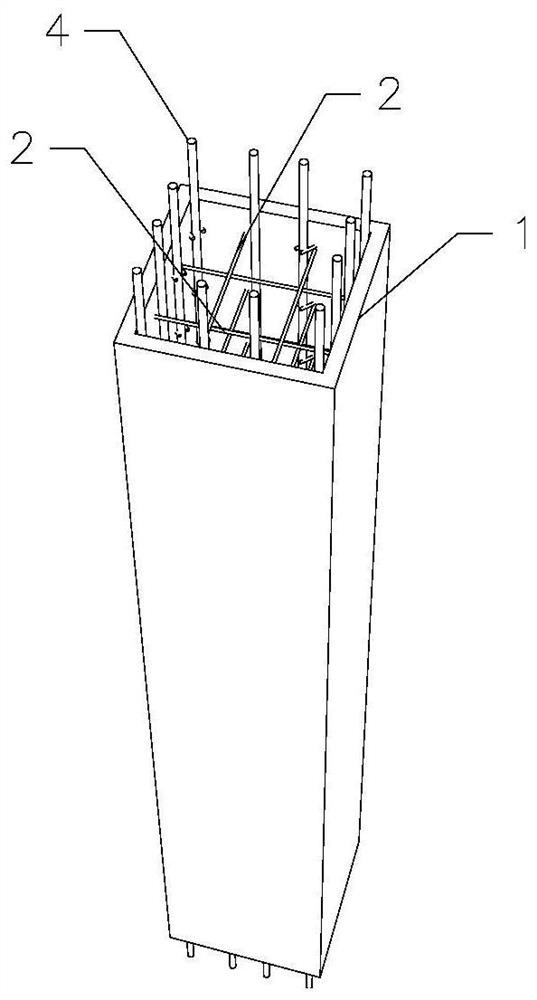

Corrugated plate-ECC fabricated composite column and construction method thereof

PendingCN113789914ASpeed up the construction progressGuaranteed integrity and shock resistanceStrutsPillarsMechanical engineeringBuilding construction

The invention provides a corrugated plate-ECC fabricated composite column and a construction method thereof, and relates to the technical field of building construction. The composite column comprises a hollow columnar corrugated plate inner shell, an upper end plate, a lower end plate, an ECC outer shell and a plurality of connecting rods, wherein the upper end plate and the lower end plate are welded to the two ends of the corrugated plate inner shell correspondingly, the upper end plate is parallel to the lower end plate and is perpendicular to the axial direction of the corrugated plate inner shell, the connecting rods are vertically fixed on the upper end plates, a plurality of penetrating holes are formed in the lower end plate, each connecting rod can correspond to one penetrating hole in the axial direction of the connecting rod, the ECC outer shell wraps the side wall of the corrugated plate inner shell in a solidified mode, one end of the ECC outer shell is connected to the upper end plate in a solidified mode, and the other end of the ECC outer shell is connected to the lower end plate in a solidified mode and avoids the penetrating holes. The composite column is simple in structure, different components support each other, load transmission is guaranteed, integrity and stability of a connecting structure are enhanced, deformation can be effectively resisted, force can be effectively transmitted, and the composite column has wide application prospects in prefabricated buildings.

Owner:HUAQIAO UNIVERSITY

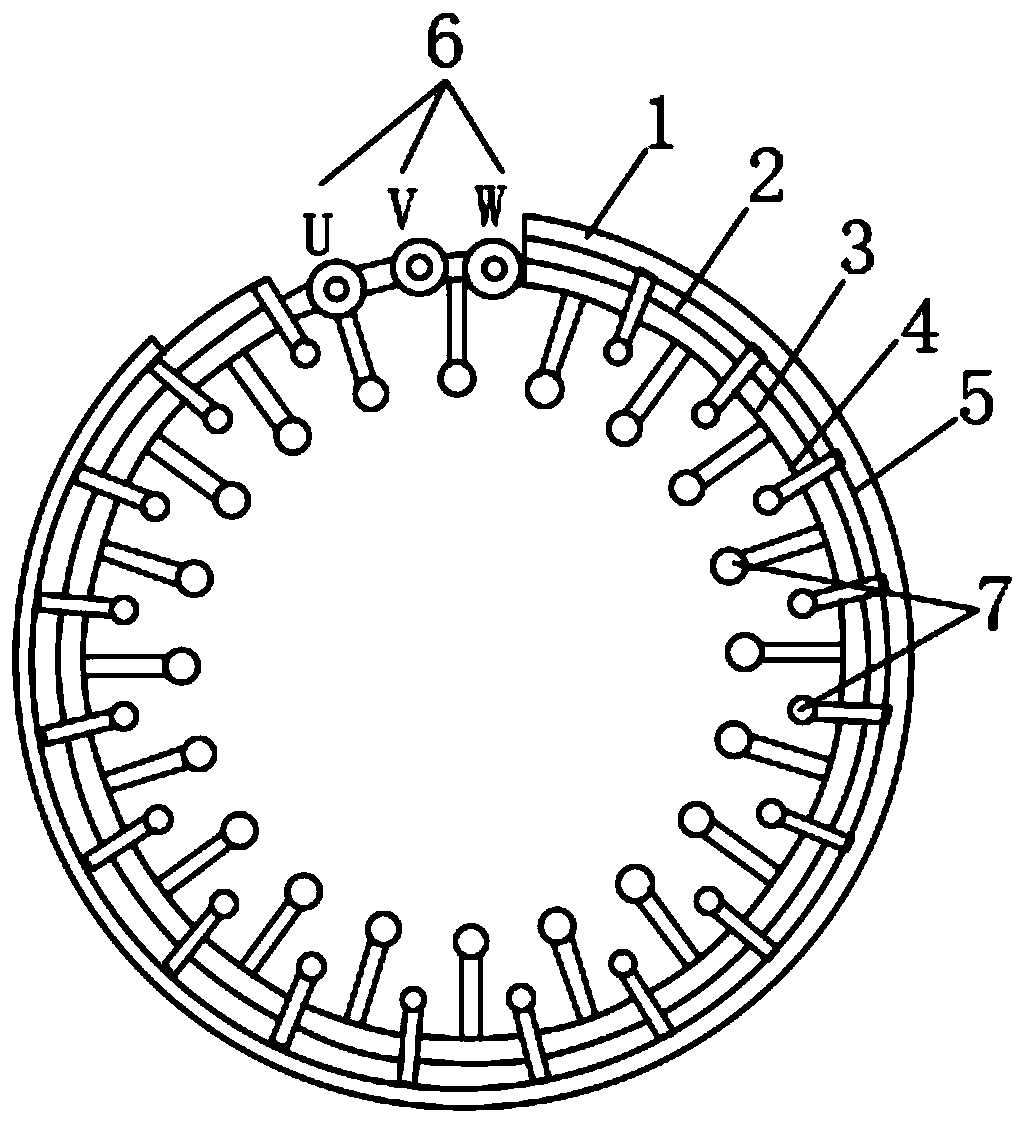

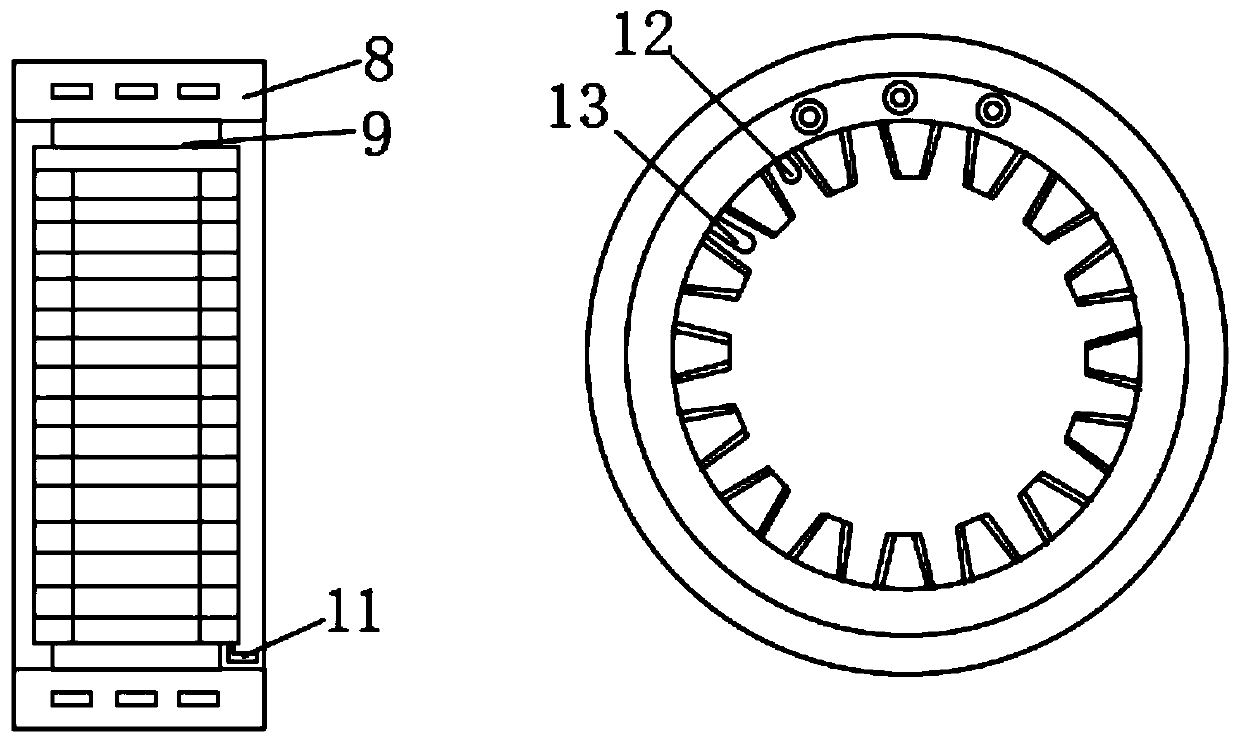

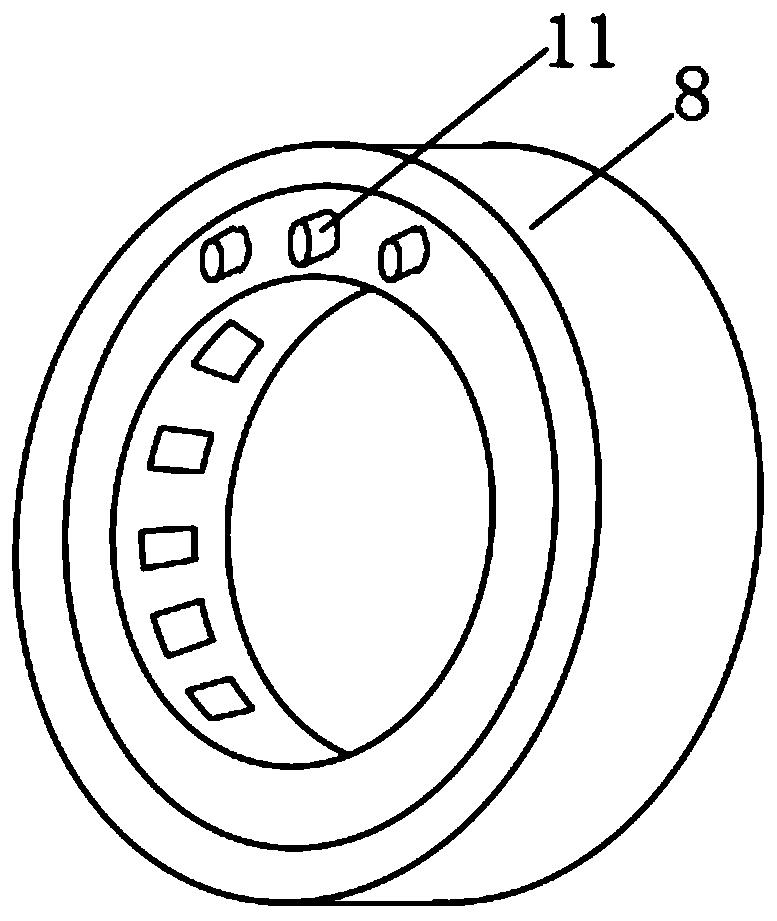

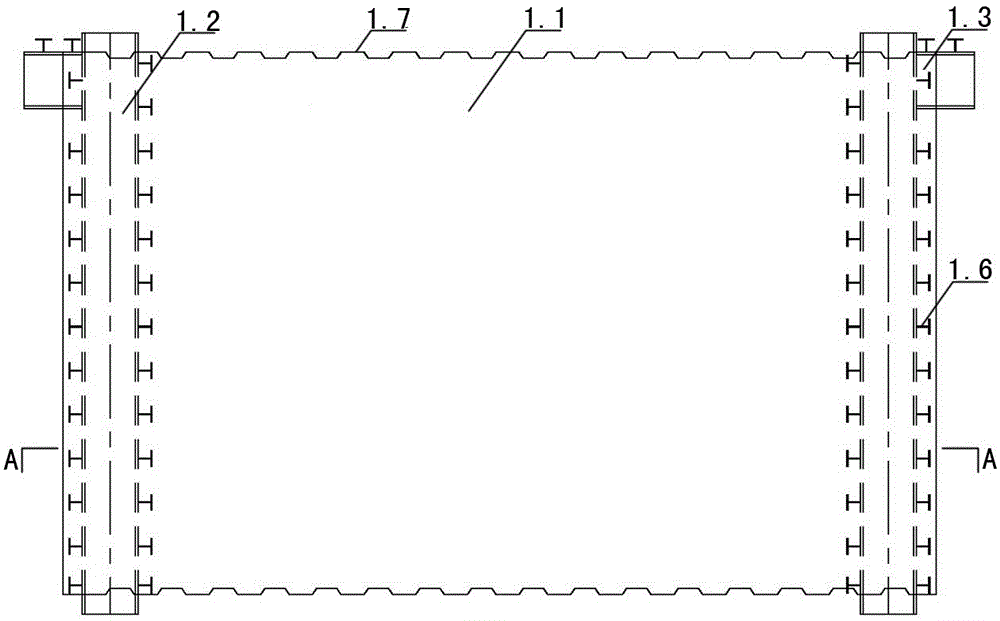

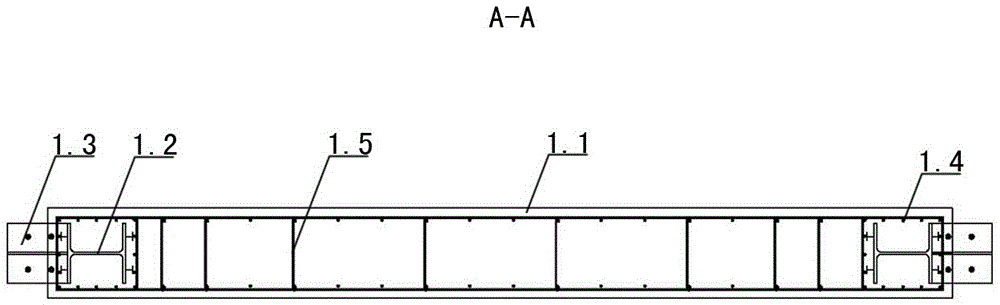

Centralized winding motor end part patch board

The invention discloses a centralized winding motor end part patch board. The patch board comprises a 1-1V phase connection copper bar, a 1-2W phase connection copper bar, a 1-3U phase connection copper bar, a 1-4 center line and 1-6U, V and W three-phase binding posts. 1-5 phase-to-phase insulation paper is arranged among the 1-1V phase connection copper bar, the 1-2W phase connection copper bar,the 1-3U phase connection copper bar and the 1-4 center line, and pins welded with a motor winding are arranged on the 1-6U, V and W three-phase binding posts and the 1-4 center line. The number of pins on the U, V and W three-phase connection copper bars and the center line connection copper bar is determined according to the number of stator slots and the number of parallel connection paths ofthe motor, the current-carrying area of the connection copper bars is determined according to the motor power and the current magnitude, punch forming and insulating encapsulation are performed to form the integrated patch board, and the processing and manufacturing process is simple.

Owner:江西麦克斯韦科技有限公司

Transmission shifter with improved feel positioner

A selector apparatus comprises a shift lever operably supported on a base for movement between gear positions, and a feel positioner mechanism with offset detent members, where a first detent engages first undulations for biasing the shift lever toward a center of a selected gear position from a first direction, and a second detent engages second undulations for biasing the selector lever toward the center of the selected gear position from a different second direction to the common center point. By the arrangement, the first and second undulations define opposing angled slopes toward the common center point. This allows the undulations to be designed to provide any desired level of biasing force toward the center point without the limitations of a single undulation defining the center point.

Owner:GHSP

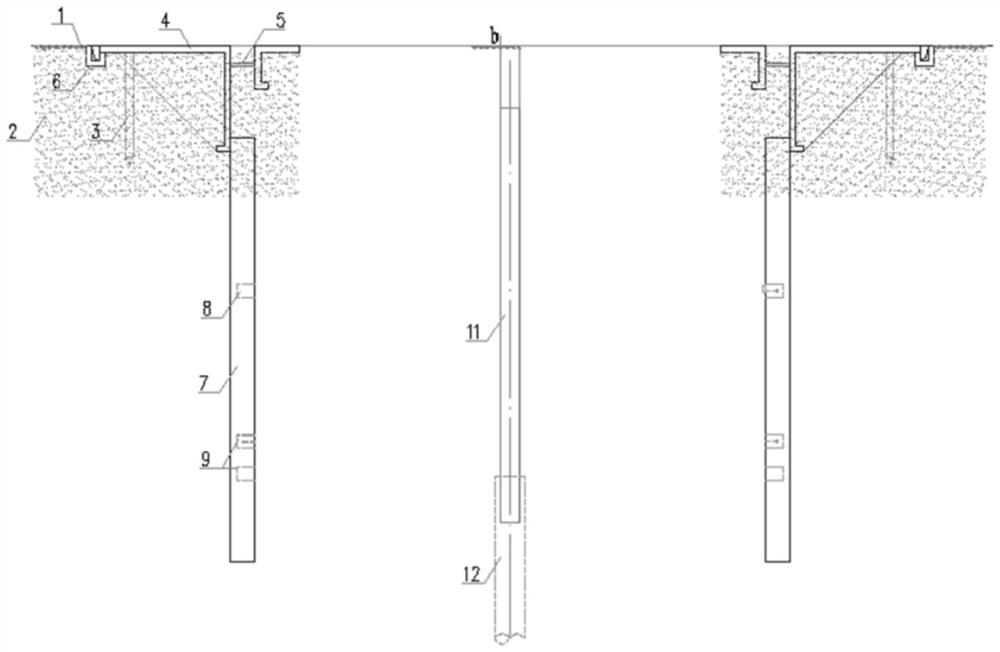

Prestress assembly type underground diaphragm wall and construction method thereof

PendingCN113431031AImprove pouring qualityReduce wall unevennessArtificial islandsProtective foundationRebarPre stress

The invention discloses a prestress assembly type underground diaphragm wall which comprises unit walls I and unit walls II which are alternately connected to form an annular structure or a polygonal structure in a surrounding manner, the adjacent ends of the unit walls I and the unit walls II are paired with each other to form closed cavities, and concrete is poured into the closed cavities so that the unit walls I and the unit walls II can be connected and fixed; the unit walls I and the unit walls II are each of a box type structure internally provided with a cavity, and reinforcement cage structures are embedded in the box type structures; and each reinforcement cage structure comprises steel bars I transversely arranged on the transverse portion of the corresponding box type structure, steel bars II vertically arranged on the transverse portion and the longitudinal portion of the corresponding box type structure, tie bars used for hooping parts of the steel bars II in the transverse portion and stirrups I used for hooping the steel bars II at the corresponding positions of the vertical portion. By means of the arrangement, the underground diaphragm wall is good in water resistance property, construction is simple, and connection is reliable.

Owner:瀚阳国际工程咨询有限公司

Double steel pipe concrete anti-seismic column with built-in rubber compound and its construction method

The invention is a novel double steel pipe concrete anti-seismic column with built-in rubber compound. Including circle in circle, square in square, circle in square, square in circle, and rectangle in rectangular cross-section, it is composed of outer steel pipe, inner steel pipe, interlayer concrete and rubber mixture. The concrete is placed between the double steel pipes, the rubber compound is filled in the inner steel pipes, and the sandwich concrete is self-compacting concrete. The rubber compound is located inside the inner steel pipe, which has a good energy dissipation and shock absorption effect, can effectively absorb earthquake energy, and can also effectively prevent fires; the double steel pipe concrete anti-seismic column with built-in rubber compound has a relatively low self-weight. The invention is the main component of the frame structure in high-rise and long-span buildings, and has the characteristics of high bearing capacity, light weight, good plasticity and toughness, good impact resistance and fatigue resistance, good earthquake resistance, good durability and the like.

Owner:SHENYANG JIANZHU UNIVERSITY

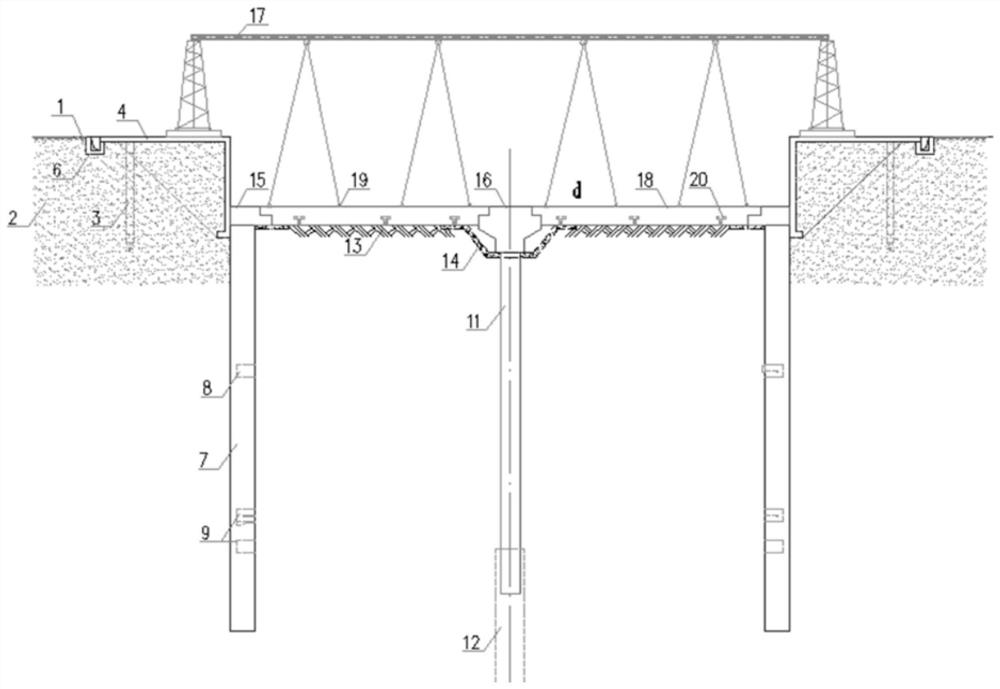

A method of assembly-type construction of open-cut underground building structures

ActiveCN109235499BFacilitate traffic reliefFavorable relocationArtificial islandsUnderwater structuresSupporting systemArchitectural engineering

The open-cut underground building structure assembly construction method of the present invention does not need to erect a temporary support system, and the temporary support system in the existing construction method is replaced by each floor plate in the permanent structure station, including the top plate, the floor plate and the bottom plate, Eliminate support removal, save a lot of waste of temporary materials, avoid structural instability caused by the change of structural force system caused by support removal and replacement, change the longitudinal beam system of the existing station structure to vertical and horizontal integrated force, and the structure is completed at one time , simple and clear, safe and reliable.

Owner:GUANGZHOU METRO DESIGN & RES INST

A ductile composite bridge deck composed of cold-formed z-shaped steel

ActiveCN112227199BPrevent rustImprove toughnessBridge structural detailsBridge materialsFillet weldBridge deck

The invention discloses a ductile composite bridge deck composed of cold-formed Z-shaped steel, which comprises cold-formed and curled Z-shaped steel, transverse steel bars and ultra-high toughness concrete. The cold-formed Z-shaped steel is continuously placed laterally along the bridge deck and welded by fillet welds to form the steel skeleton of the bridge deck. The lower flange of the cold-formed Z-shaped steel is longer, which plays the role of external reinforcement of the plate surface; the upper flange is shorter and has a row of round holes on it, and the transverse steel bars pass through each cold-formed Z-shaped steel flange through the round holes. The ultra-high toughness concrete is poured on the steel skeleton of the bridge deck to protect the steel skeleton of the bridge deck. In the composite bridge deck system proposed by the present invention, the ultra-high toughness concrete can ensure that no or only tiny cracks below 100 microns will be generated, and the toughness and durability of the structure will be improved; The anti-shear and pull-out effects of the studs are improved, and the out-of-plane stability of the bridge deck is improved, the material cost and construction complexity are significantly reduced, and the fatigue performance is superior.

Owner:ZHEJIANG UNIV

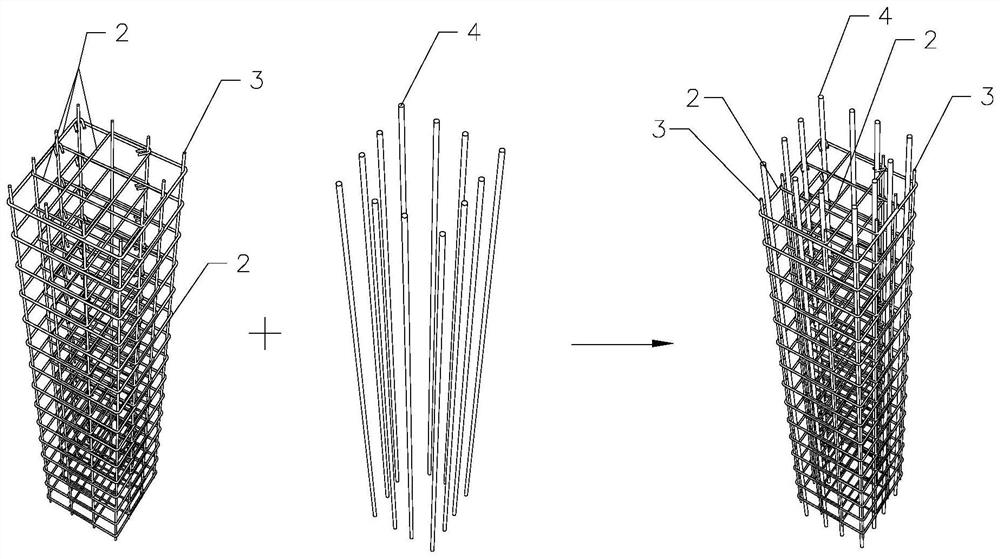

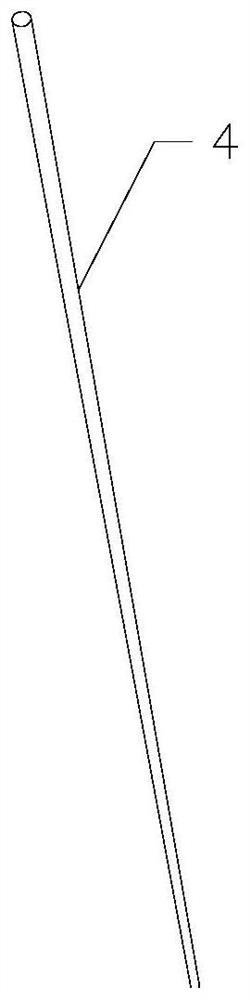

Hollow thin-wall concrete composite column

PendingCN114562072AImproved transport and hoisting efficiencyReduce energy consumption and transportation costsStrutsBuilding reinforcementsRebarHollow core

The invention discloses a hollow thin-wall concrete composite column which comprises a pre-buried steel bar framework. The concrete shell wraps the outer side of the pre-embedded steel bar framework in a matched mode, the pre-embedded steel bar framework is connected with the concrete shell, so that the pre-embedded steel bar framework and the concrete shell are fixed to form the prefabricated hollow column, and after the prefabricated hollow column is transported to a site, longitudinal steel bars are inserted into the prefabricated hollow column in a penetrating mode and then hoisted in place. And finally, concrete is poured to form the concrete composite column. In the assembling production process, the operation process is simple and convenient, and factory manufacturing is easy to achieve; in the on-site construction process, components are light and extremely easy to hoist, longitudinal load-bearing steel bars are inserted on site, a prefabricated concrete shell is thin, the contradictions that longitudinal steel bars of a traditional prefabricated concrete column are complex in connection, the steel bars are prone to dislocation and the like are avoided, prefabricated components are light in self weight and extremely easy and convenient to transport and hoist, a large amount of cast-in-place concrete is adopted, and prefabricated part concrete is thin; and the overall shape of the component is very good.

Owner:江苏万斯达建筑科技有限公司

Prefabricated mixed limb wall system and its construction method

InactiveCN104032860BGood extensibilityExcellent shear yield energy dissipation performanceWallsBuilding material handlingFloor slabButt joint

Disclosed are an assembly-type mixed coupled wall system and a construction method thereof. The assembly-type mixed coupled wall system comprises wall units which are connected in the horizontal direction and the vertical direction respectively, a floor slab is arranged between the wall units connected in the vertical direction, the left wall unit and the right wall unit in the horizontal direction are connected through an energy-dissipating beam, anti-shear studs are fixed onto the energy-dissipating beam, the two ends of the energy-dissipating beam are fixedly connected with non-energy-dissipating short beams of the two wall units respectively, the upper wall unit and the lower wall unit in the vertical direction are correspondingly and fixedly connected through steel columns and a steel bar framework, and the steel columns between the upper wall unit and the lower wall unit are fixed in a butt-joint mode and poured in the floor slab. The construction method of the assembly-type mixed coupled wall system is simpler, faster and more efficient and comprises the procedures of prefabrication and on-site assembly, the two procedures can be conducted at the same time, the concrete on-site wet construction quantity is reduced, the construction speed is increased, generation of construction waste is reduced and the construction method can be applied to construction of coupled walls in constructional engineering.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

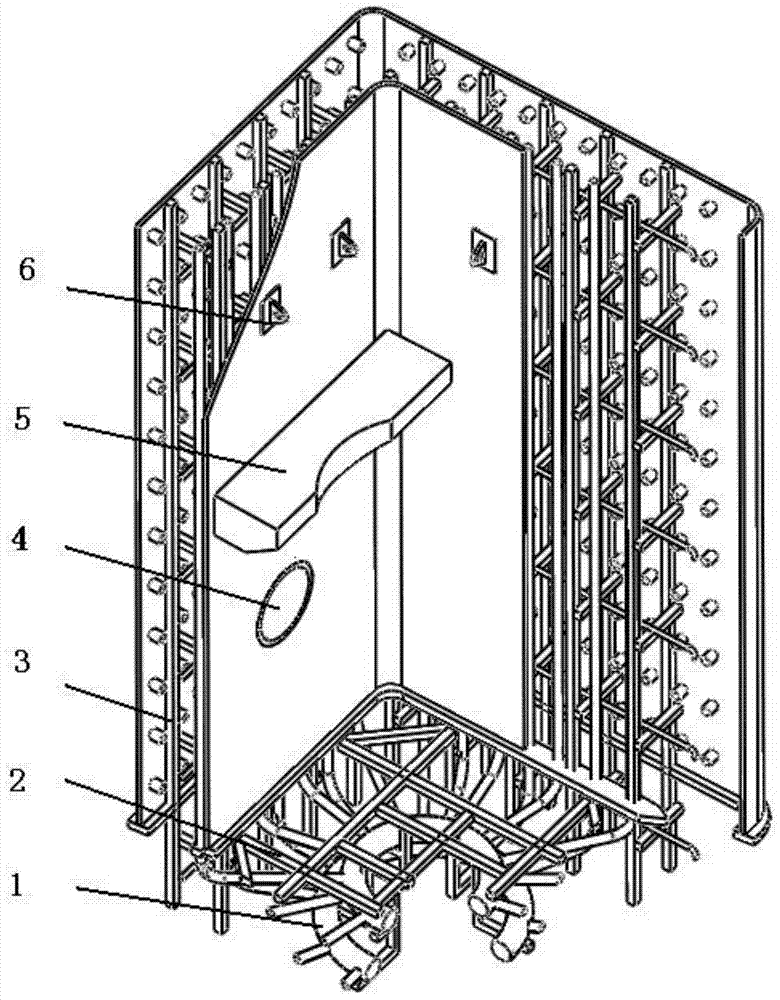

A high temperature gas-cooled reactor nuclear power plant steam generator cabin module

The invention belongs to the nuclear power technique of high temperature gas cooled reactors, and particularly relates to a nuclear power station steam generator cabin module for a high temperature gas cooled reactor. The nuclear power station steam generator cabin module comprises a wall structure, a bottom structure, a shielding cooling water system, an evaporator supporting embedded part and a penetrating part which is installed on the wall structure in a penetrating mode. The wall structure comprises an outer wall body and an inner wall body. The inner wall of the outer wall body and the inner wall of the inner wall body are provided with pieces of supporting angel steel. A shielding cooling water pipe is arranged on the inner wall body. Shearing resistance pins are longitudinally and transversely fixed to the inner walls. A plurality of parallel supporting cross beams are arranged between the inner wall body and the inner wall body in the direction which is perpendicular to the pieces of supporting angel steel. The wall structure is composed of the outer wall body and the inner wall body and made of Q345-C steel plates, and meanwhile, the amount of tied steel arranged between the inner wall body and the outer wall body is effectively decreased through the steel structure which is composed of the pieces of supporting angel steel, the shearing resistance pins and the supporting cross beams; accordingly, the cost is reduced, and more importantly, the stability is good. The supporting embedded part is of a box body structure, internally provided with rib plates and independently and integrally machined, cross construction between the supporting embedded part and a water pipe rebar is avoided, the construction difficulty is reduced, and the construction precision is improved.

Owner:HUANENG SHANDONG SHIDAOBAY NUCLEAR POWER CO LTD

Non-welding fabricated steel pipe concrete beam-column joint and its construction method

The invention relates to a solderless assembly type steel pipe concrete beam column node, which comprises a steel pipe concrete column, wherein an annular sleeve is arranged outside the steel pipe concrete column; a plurality of reinforced concrete beams are annularly arranged at the circumferential side of the annular sleeve. The invention also relates to a construction method of the solderless assembly type steel pipe concrete beam column node. The solderless assembly type steel pipe concrete beam column node and the construction method have the advantages that the structure design is simple, compact and reasonable; all mechanical properties of the node are met; the structure assembly is realized; the assembling speed of components is accelerated; the requirements and the characteristics of an assembly type system are fully met.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com