Prestress assembly type underground diaphragm wall and construction method thereof

An underground diaphragm wall and construction method technology, which is applied in artificial islands, sheet pile walls, water conservancy projects, etc., can solve the problems of difficult wall quality assurance, high construction risk, and easy leakage of joints, etc., so as to improve the lateral force performance and Waterproof performance, reduce the effect of binding steel bars, and improve the quality of pouring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings.

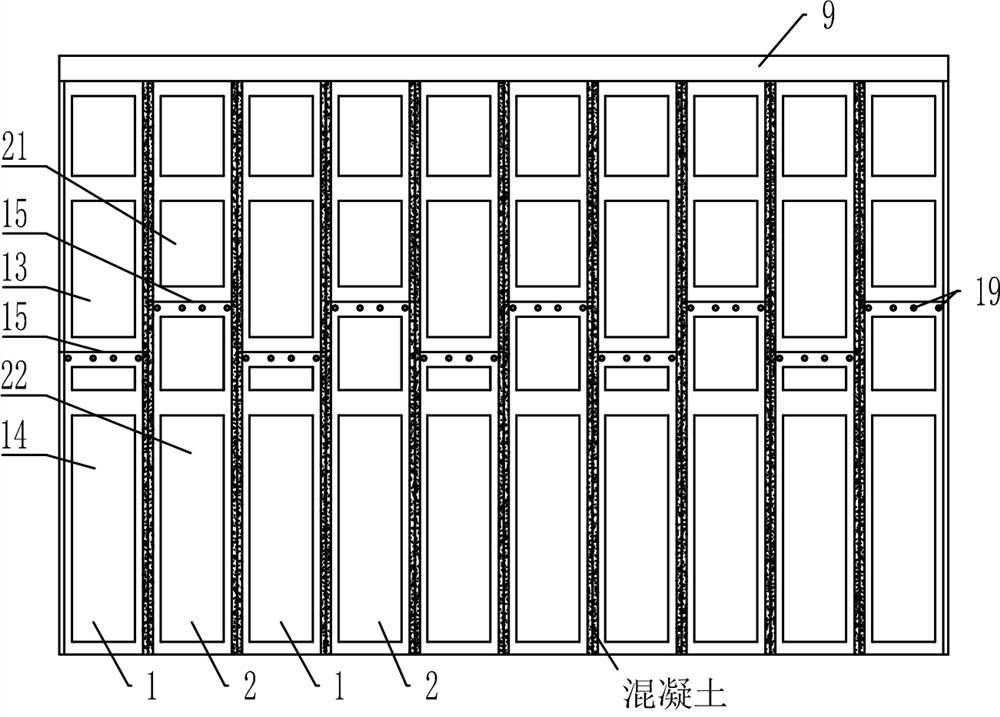

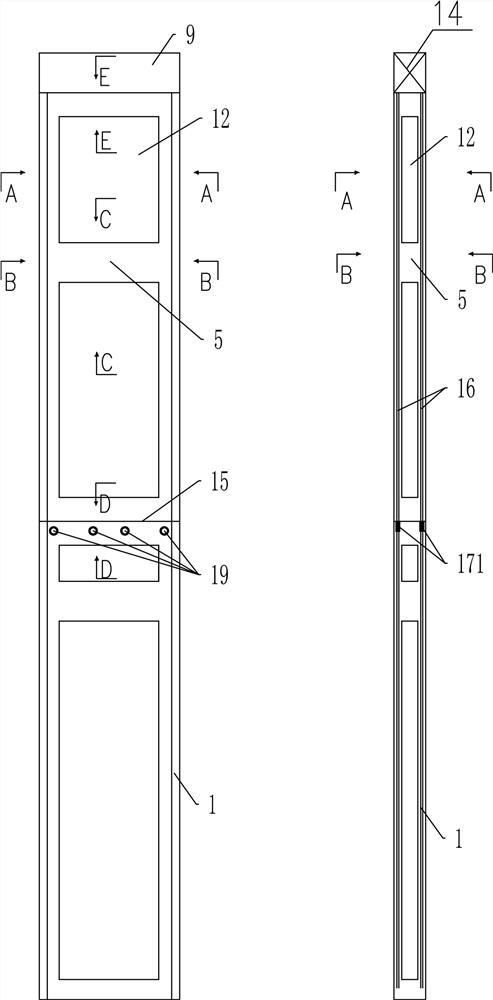

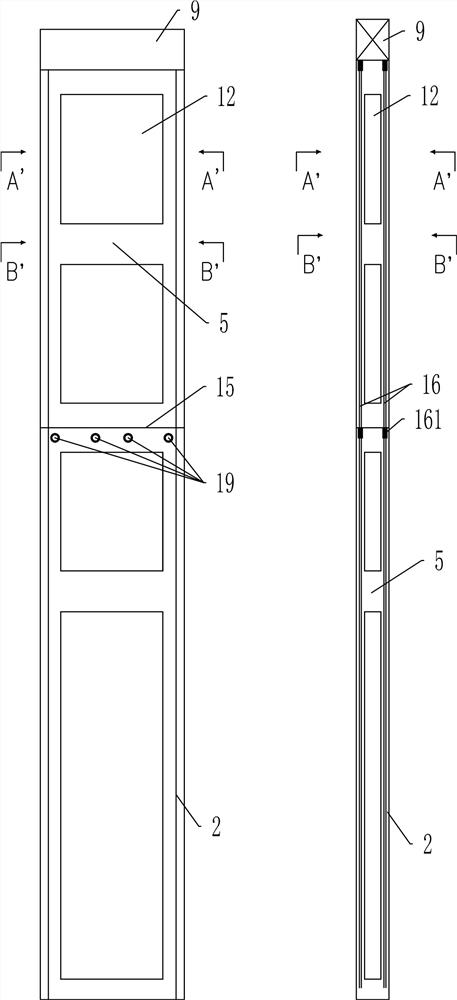

[0055] Such as Figure 1-12As shown, a prestressed assembled underground continuous wall includes unit walls I1 and unit walls II2 that are alternately connected to form a ring structure or a polygonal structure, and the adjacent ends of the unit walls I1 and unit walls II2 are paired with each other A closed cavity 3 is formed, and the unit wall I1 and the unit wall II2 are connected and fixed by pouring concrete in the closed cavity 3. In the present invention, the unit wall I1 and the unit wall II2 are provided with matching grooves 11, and the unit wall I1 The groove 11 of the unit wall Ⅱ2 cooperates with the groove 11 of the unit wall Ⅱ2 to form a closed cavity 3, and at the ends of the unit wall Ⅰ1 and the unit wall Ⅱ2, two or more sets of inserting ribs 18 are respectively provided, that is, one end of the inserting rib 18 is located at the unit wall Ⅰ1 or In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com