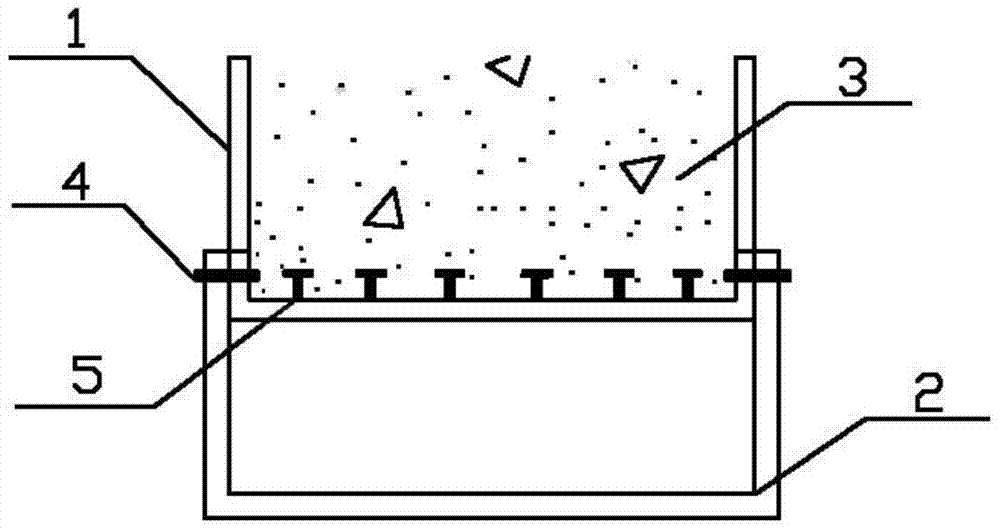

Double-layer channel-recycled concrete composite beam

A technology of recycled concrete and composite beams, applied in the field of composite beams, can solve the problems of incomplete bending resistance of section steel, unfavorable factory mechanized production, low production efficiency, etc., and achieve the effects of improving space utilization, light weight and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

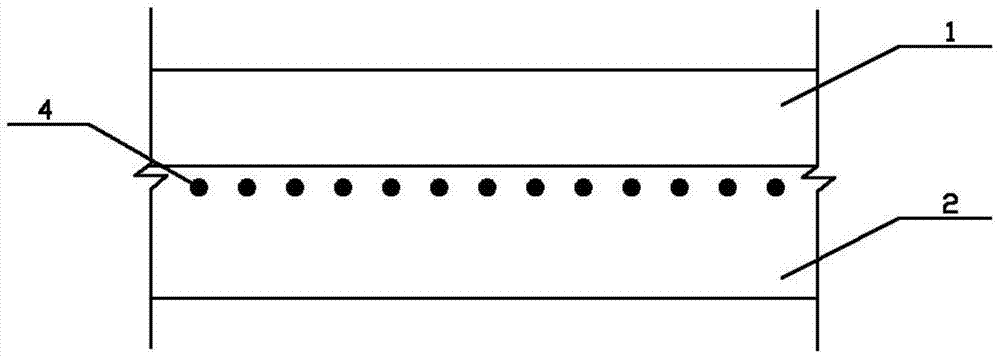

Method used

Image

Examples

Embodiment 1

[0018] The weight ratio of each component in Example 1 is: water: cement: sand: discarded bricks: discarded concrete blocks=1:2.27:2.27:1.04:5.21. Standard methods were used for testing, and the experimental data were as follows: slump was 180, excellent workability, 7-day compressive strength 28.5MPa, 28-day compressive strength 43.5MPa.

[0019] 1. Determine the preparation strength f cu,0

[0020] f cu.0 = F cu,k +1.645σ

[0021] When the strength grade of concrete is C35, σ=5.0MPa, then

[0022] f cu,0 =48.2MPa

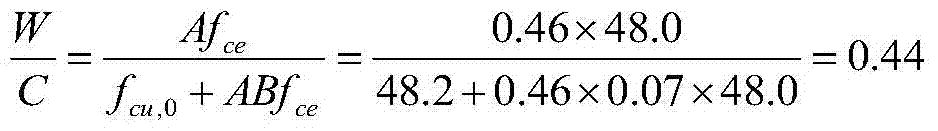

[0023] 2. Preliminarily determine the water-cement ratio W:C

[0024] Because the 28d measured strength of the cement used in this experiment is f ce Unknown, it is expected that the measured strength of cement at 28d can reach 48.0MPa. Coarse aggregate is crushed stone, A=0.46, B=0.07

[0025]

[0026] 3. Preliminary estimation of unit water consumption

[0027] The maximum particle size is 40mm. Because the waste concrete blocks are subjected to a large external force d...

Embodiment 2~5

[0042] In Examples 2 to 5, the related process refers to Example 1, and the relevant parameters are adjusted to obtain the following ratios:

Embodiment 2

[0043] The weight ratio of each component in Example 2 is: water: cement: sand: discarded bricks: discarded concrete blocks=1:2.11::2.48:1.15:5.25. Standard methods were used for testing, and the experimental data are as follows: slump is 160, excellent workability, 7-day compressive strength 22.5MPa, 28-day compressive strength 45MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com