Assembly type laminated slab anchoring structure convenient to construct and connecting mode thereof

An anchoring structure and laminated board technology, applied in the direction of structural elements, floor slabs, building components, etc., can solve the problems of large workload and low construction efficiency, and achieve the effect of reducing the use of materials, convenient construction, and reducing workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

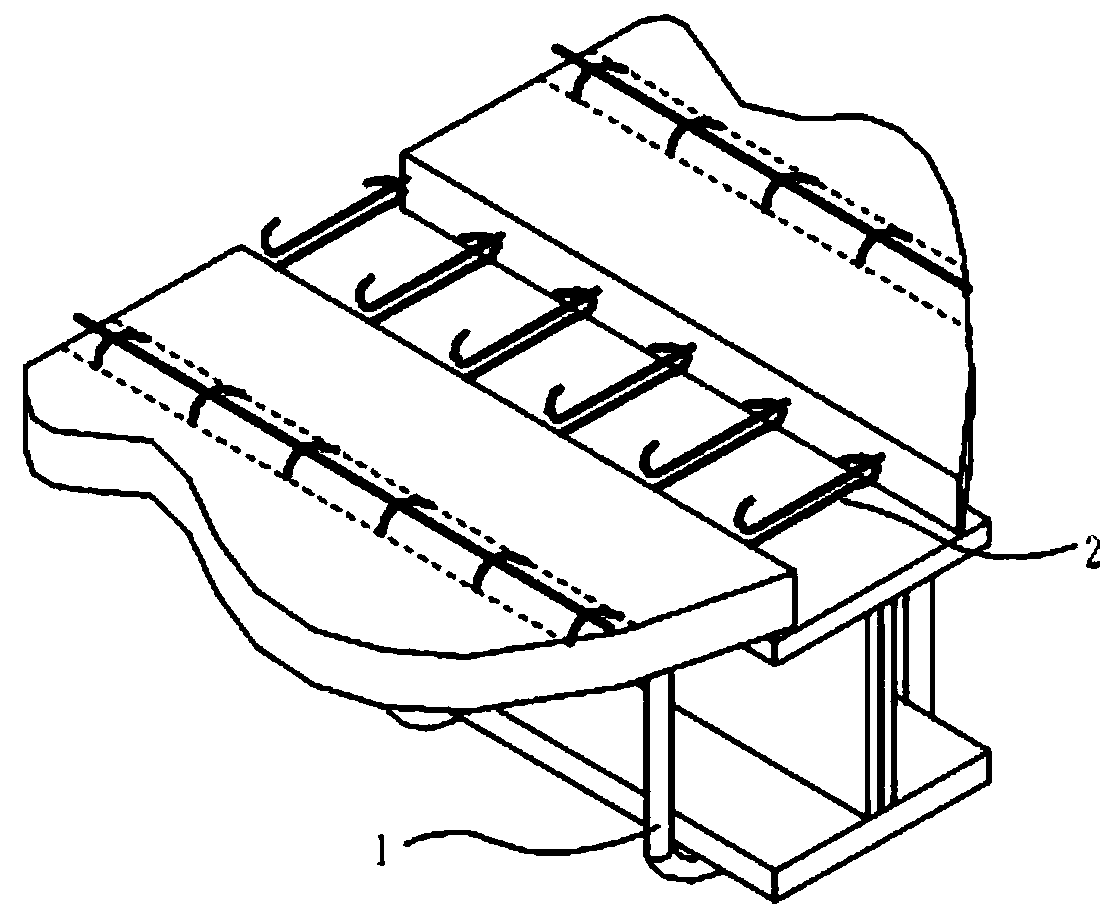

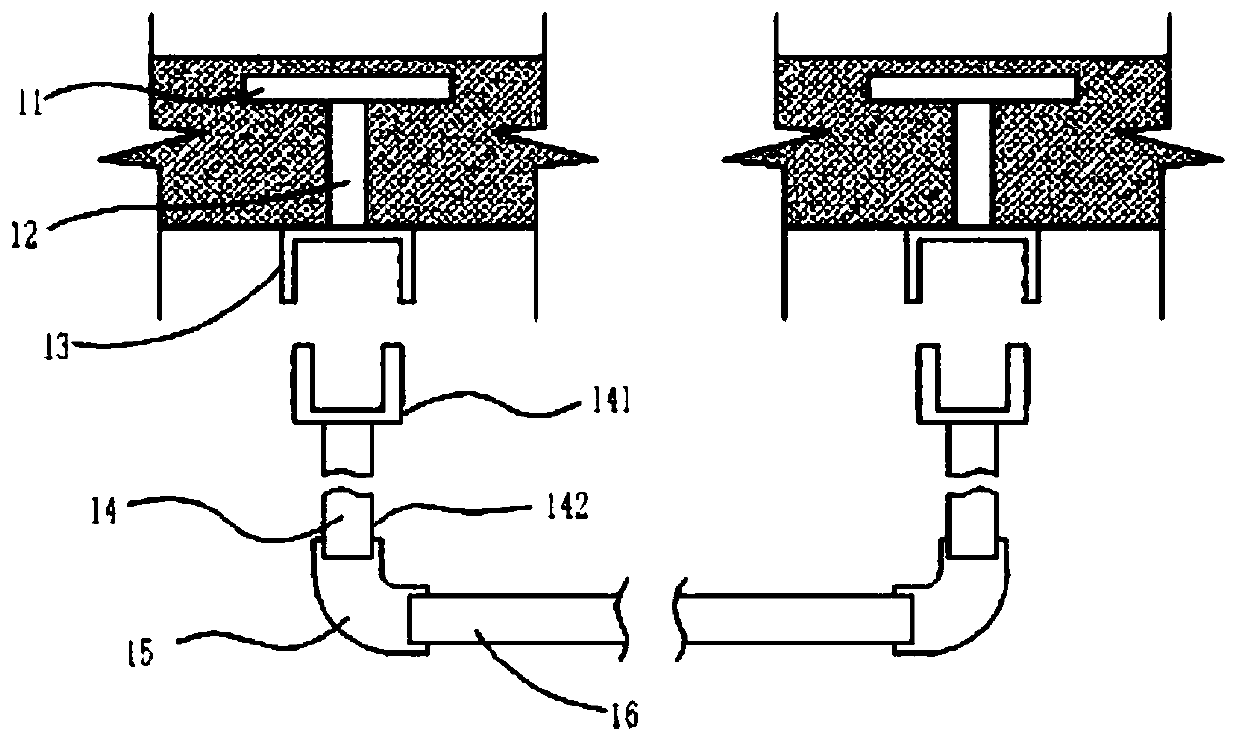

[0033] Embodiment 1: as figure 1 , 2 A prefabricated laminated plate anchoring structure that is convenient for construction is shown, including a first anchor 1 for anchoring connection with the outside, and a second anchor 2 for anchoring connection between the prefabricated laminated plates themselves;

[0034] The first anchor 1 includes embedded parts and connectors;

[0035] The embedded part includes the embedded bottom plate 11, the embedded connecting rod 12, and the first connecting cap 13; the connecting part includes the connecting rod 14, the connecting elbow 15 and the second connecting rod 16, and the connecting rod 14 includes the second connecting cap 141 and the a connecting rod 142;

[0036] One end of the pre-embedded connecting rod 12 is welded on the pre-embedded bottom plate 11, and the first connecting cap 13 is installed on the other end of the pre-embedded connecting rod 12;

[0037] like figure 2 As shown, the second connecting cap 141 can be in...

Embodiment 2

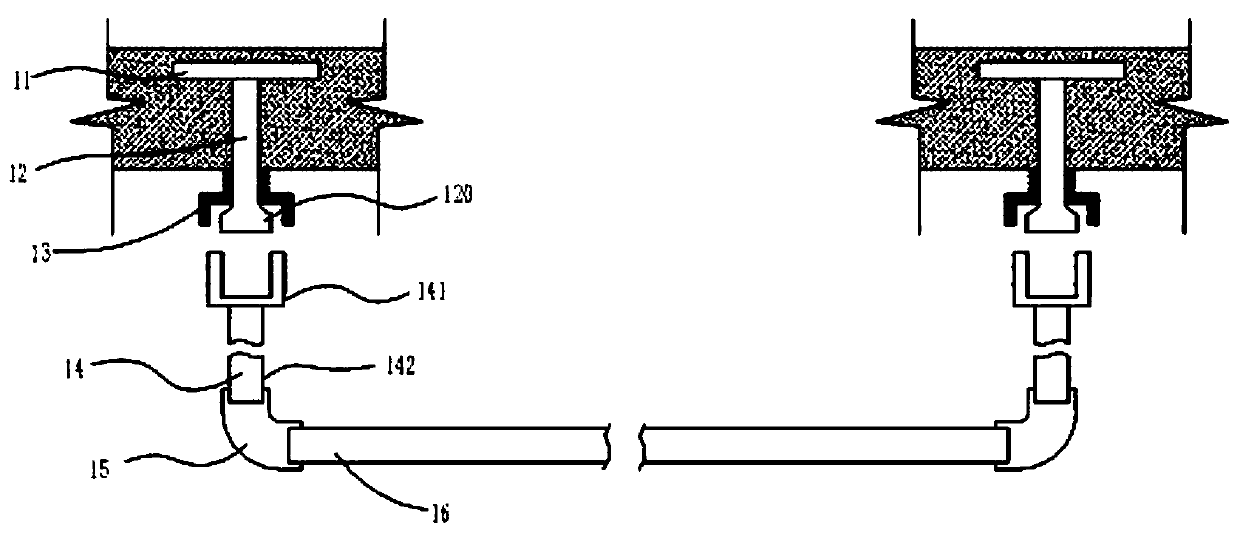

[0045] Embodiment 2: Different from Embodiment 1: as image 3As shown, the end of the embedded connecting rod 12 connected to the first connecting cap 13 is equipped with a mounting head 120, and the outer wall of the mounting head 120 is provided with threads; the first connecting cap 13 is movably installed on the embedded connecting rod 12, and the first connecting The inner wall of the cap 13 is provided with threads, and the inner and outer walls of the second connecting cap 141 are provided with threads corresponding to the threads on the mounting head 120 and the first connecting cap 13; The outer wall of the second connecting cap 141 is threadedly connected with the first connecting cap 13 .

Embodiment 3

[0046] Embodiment 3: Different from Embodiment 2: as Figure 4 As shown, the embedded base plate 11 adopts a channel steel base plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com